Posted on Thursday, November 30, 2023

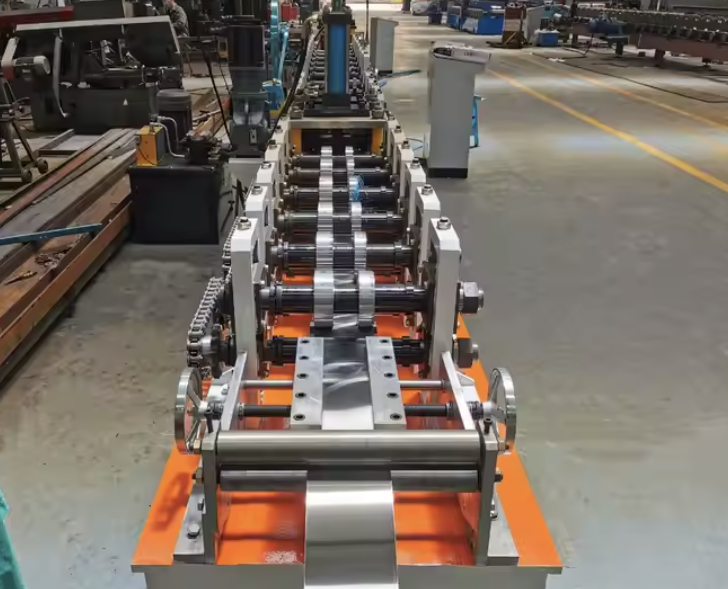

Roll forming machines have become a valuable asset in many industries across the Seychelles, particularly in construction, manufacturing, and infrastructure. While Seychelles is known for its stunning landscapes and tourism, the demand for quality metal fabrication—especially for roofing, framing, and structural components—has steadily grown in urban developments and industrial projects. Whether for local production or small-scale exports, roll forming machines play a vital role.

In this comprehensive guide, we’ll explore the most popular types of roll forming machines used in Seychelles, including their specifications, profiles, industries, locations of high usage, maintenance tips, pricing ranges, setup and operation processes, and key manufacturers. We’ll also explain how Machine Matcher can help you select the ideal roll forming machine for your needs.

Specifications:

Roller Material: GCr15 steel with heat treatment

Frame Structure: 300–400 H-beam welded

Drive Type: Chain or gearbox

Motor Power: 5.5 kW to 15 kW

Cutting System: Hydraulic guillotine

PLC System: Delta or Siemens

Profiles Used: Trapezoidal, corrugated, and step tile roofing sheets

Industries: Residential and commercial roofing, tourism resorts, public buildings

Popular in: Victoria (Mahé), Anse Boileau, Cascade, Beau Vallon

Specifications:

Roller Material: High-grade alloy steel

Adjustable Sizes: 80mm to 300mm (width)

Changeover Time: Manual or automatic within 5–15 minutes

Hydraulic Cutting: Precise and burr-free

Profiles Used: Structural purlins for roofs and walls

Industries: Commercial construction, logistics warehouses, airports

Popular in: Mahé industrial zones, Providence, and regional storage developments

Specifications:

Material Thickness: 0.4–0.8 mm galvanized or pre-painted steel

Machine Speed: 8–15 meters/minute

Cutter System: Manual or automatic hydraulic

Profiles Used: K-style and half-round gutter profiles

Industries: Resort maintenance, residential housing, tourism infrastructure

Popular in: Eden Island, Praslin, La Digue

Specifications:

Motor Power: 7.5–11 kW

Rollers: 16–22 stages depending on design

Material Used: Galvanized or mild steel, 1.0–2.0 mm thickness

Controller: Fully automatic PLC-based system

Profiles Used: Door frame profiles, shutter slats, tracks

Industries: Industrial garages, secure storage, retail shops

Popular in: Victoria, inner islands, and logistics centers

Construction: For roofing, siding, and steel framing systems

Tourism & Hospitality: Roof panels and gutters for resorts and villas

Government Infrastructure: Warehouses, public service buildings

Retail & Logistics: Shutters, doors, storage facility cladding

Renewable Energy: Metal profiles for solar mounting structures (growing sector)

Regular maintenance ensures your machines run smoothly and extend their lifespan. Here are the key steps:

Daily Cleaning: Remove debris and dust after each shift.

Lubrication: Apply grease to gears, bearings, and chains weekly.

Roller Inspection: Check for surface wear or misalignment monthly.

Hydraulic Oil Check: Replace oil every 6 months to avoid pressure issues.

PLC System Backup: Keep regular backups of your machine settings.

Alignment Checks: Ensure rollers and cutter blades are aligned quarterly.

Professional Servicing: Annual servicing by certified technicians is recommended.

Low-End Machines:

Manual or semi-automatic systems

Basic single-profile machines

Estimated Price: $18,000 – $30,000 USD

Mid-Range Machines:

Fully automatic PLC systems

Better material handling and hydraulic cutting

Estimated Price: $35,000 – $60,000 USD

High-End Machines:

Servo motors, remote PLC control, fast changeovers

Dual-profile or interchangeable line machines

Estimated Price: $70,000 – $120,000+ USD

Custom features, stackers, coil cars, or automated packaging units will add to the cost.

While Seychelles has limited local manufacturing, most machines are imported and supported by international suppliers or regional partners in the Middle East, Asia, and Europe. Key suppliers include:

Chinese Roll Forming Manufacturers (Zhongyuan, Xiamen, Liming)

Turkish Suppliers with CE-certified machines

European Brands offering premium high-speed lines

Machine Matcher – a global network connecting buyers in Seychelles with the best-fit machine from over 170+ countries

Unpack and inspect the machine upon delivery

Secure the machine on level ground with anchor bolts

Connect power supply (ensure compatibility with local voltage)

Install the uncoiler and feed the coil

Configure the PLC system with profile specs

Test with a trial run and inspect the first few outputs

Start with the emergency stop engaged and clear the line

Power up the machine and slowly feed the material

Monitor for noise, vibrations, or misfeeds

Maintain a safe zone around the moving line

Use trained staff for loading, monitoring, and unloading

Q1: Can I use a roll forming machine for multiple profiles?

Yes, with a multi-profile machine or quick-change cassette system. However, single-profile machines are more cost-effective if you only produce one shape.

Q2: Do I need a large factory to install a roll forming machine?

Not necessarily. Many compact roll forming machines are designed for small workshops or container-sized operations.

Q3: What power supply is needed in Seychelles?

Most machines require 3-phase 380V, 50Hz power. Always confirm before purchase to ensure compatibility.

Q4: Can I import a used roll forming machine?

Yes. Machine Matcher can help you find quality pre-owned machines that are serviced and ready for use.

Q5: What profile is best for roofing in Seychelles?

Trapezoidal and corrugated profiles are most common due to their strength, water flow efficiency, and ease of installation.

Machine Matcher connects Seychellois buyers with the most suitable roll forming machines globally. Whether you’re starting a new metal fabrication business or upgrading your current equipment, we make the process easy and reliable. Here's how we help:

Custom Profile Matching: We find machines based on your exact profile drawing and material thickness.

New & Used Options: Access to a wide range of machines depending on your budget.

Technical Consultation: Our experts guide you from selection to installation.

Shipping & Logistics: We coordinate delivery to Seychelles, ensuring smooth customs and port handling.

After-Sales Support: Get help with maintenance, spare parts, and upgrades.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let us help you find the roll forming machine that fits your business in Seychelles.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.