Sudan, with its growing demand for infrastructure, housing, and commercial development, has seen a steady increase in the use of roll forming machines across various industries. These machines are essential in producing consistent, high-quality metal profiles used in roofing, wall cladding, framing systems, and structural components. In this blog, we explore the most popular roll forming machines in Sudan, their specifications, applications, costs, maintenance requirements, and more.

1. Most Popular Roll Forming Machine Types in Sudan

a. Roofing Sheet Roll Forming Machines

- Specifications:

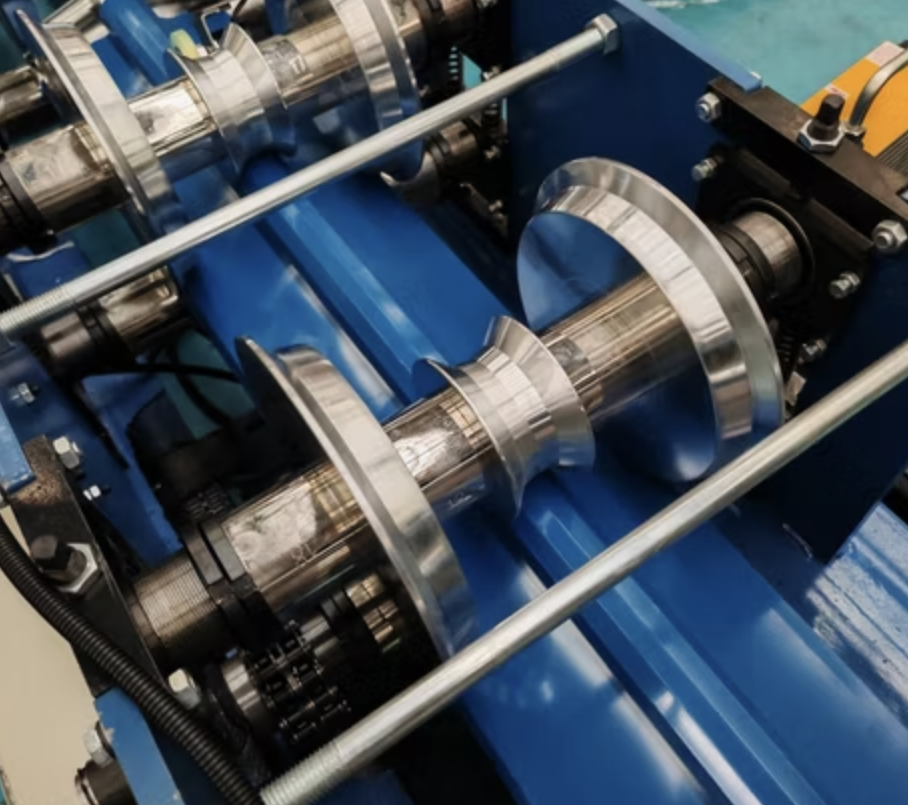

- Roller Material: GCr15 steel with hard chrome coating

- Frame Structure: 300-350H steel welded frame

- Transmission: Gearbox or chain drive

- Cutting System: Hydraulic with Cr12 cutting blades

- Speed: 10-15 meters per minute (standard) / up to 40 m/min (high-speed)

- PLC Control: Siemens or Delta system

- Profiles Used: Corrugated sheets, IBR profiles, trapezoidal roofing sheets

- Industries: Construction, roofing contractors, metal building manufacturers

b. C/Z Purlin Roll Forming Machines

- Specifications:

- Interchangeable C & Z profiles without tool change

- Punching: Servo feeding with hydraulic punching unit

- Thickness: 1.5mm to 3.0mm steel

- Cutting: Flying hydraulic cutter

- Output Speed: 12-18 m/min

- Profiles Used: C purlins, Z purlins, U channels

- Industries: Industrial construction, steel structure projects

c. Door Frame and Shutter Roll Forming Machines

- Specifications:

- Roller Material: GCr15

- Motor: 7.5kw to 15kw depending on gauge

- Sheet Thickness: 0.8mm to 2.0mm

- Forming Stations: 12-20

- Pre-punching and notching unit included

- Profiles Used: Door frames, roller shutter slats

- Industries: Steel door manufacturers, commercial building sector

d. Highway Guardrail Roll Forming Machines

- Specifications:

- Material: 2.5mm to 4.0mm steel

- Profile: W-beam or three-beam guardrails

- Drive: Gearbox with strong frame support

- Punching: High-speed hydraulic unit

- Speed: 8-12 m/min

- Profiles Used: W and thrie beam highway guardrails

- Industries: Road safety and infrastructure

2. Main Cities and Areas Using Roll Forming Machines in Sudan

- Khartoum: Capital city with extensive industrial development

- Omdurman: Major urban area with active commercial metalwork industry

- Port Sudan: Increasing use in logistics and shipping construction

- El Obeid and Nyala: Regions with growing demand for agricultural and rural infrastructure

3. Maintenance Requirements

Proper maintenance ensures long service life and optimal machine performance:

- Daily Checks: Lubrication of rollers and chains, checking bolts and electrical wiring

- Weekly Tasks: Inspect hydraulic oil levels, clean sensors and control panels

- Monthly Maintenance: Check roller alignment, inspect cutting blades, clean punching units

- Annual Service: Replace worn rollers, service PLC system, calibrate the entire line

4. Machine Setup and Operation

Setup Steps:

- Position the machine on a level surface with proper alignment

- Connect to power supply (usually 380V/50Hz, customizable)

- Install decoiler and load coil

- Program profile settings into the PLC

- Run test sheet and make adjustments

Operation:

- Trained operators feed coil into the machine

- PLC system controls the profile dimensions

- Hydraulic unit performs cutting and punching

- Formed sheet exits into run-out table or automatic stacker

5. Machine Costs in Sudan

- Low-End Machines: $20,000 to $35,000

- Standard speed, manual decoiler, basic PLC system

- Mid-Range Machines: $40,000 to $65,000

- Includes hydraulic cutters, inverter control, auto stacker

- High-End Machines: $70,000 to $120,000+

- High-speed, fully automated with remote monitoring, advanced punching, fast profile changeover

6. Local and International Manufacturers

In Sudan, most machines are imported. However, a few local fabricators offer custom solutions:

- Local Fabricators: Based in Khartoum industrial zones; produce simple profile machines

- International Brands:

- Chinese manufacturers (widely used due to affordability)

- Turkish and Indian brands (preferred for mid-range performance)

- European machines (high-end projects)

7. Frequently Asked Questions

Q: What type of power supply is needed for roll forming machines in Sudan?

A: Most machines require 380V/50Hz three-phase power. Some can be configured for 220V/60Hz.

Q: Can one machine produce multiple profiles?

A: Some machines are adjustable or come with cassette-type systems for quick profile changeovers.

Q: What is the delivery time for imported machines?

A: Typical delivery takes 45-75 days depending on the manufacturer.

Q: Is operator training required?

A: Yes, training is essential. Most suppliers provide installation and operator training onsite.

Q: How long does a machine last?

A: With proper maintenance, 10-15 years or more.

8. Why Machine Matcher is the Best Choice for Sudanese Buyers

Choosing the right roll forming machine for your profile and industry needs is critical. Machine Matcher connects Sudanese businesses with the right manufacturers worldwide, offering:

- Expert advice tailored to your profile and budget

- New and used machines to fit all project sizes

- Shipping, installation, and operator training support

- Flexible customization based on Sudan’s industrial needs

- Large database of machines ready to ship or build

We understand the market and provide personalized solutions to help you get the most out of your investment. Whether you're producing roofing panels in Khartoum or guardrails in Port Sudan, Machine Matcher helps you make the best choice.

Contact Machine Matcher

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]