Posted on Thursday, September 26, 2024

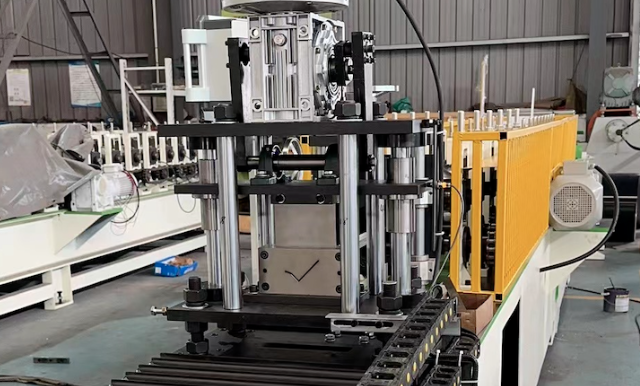

The metal drip edge is a vital component in roofing systems, ensuring water is directed away from the roof and protecting the structure from moisture damage. As demand for metal drip edge continues to grow, manufacturers are turning to automation in roll forming machines to enhance their production processes. This shift towards automation offers several benefits, including reduced labor costs, faster production times, and consistent product quality.

Traditional manufacturing processes for metal drip edge require skilled labor for tasks such as manual cutting, bending, and shaping. These processes can be time-consuming and costly, especially when handling large volumes. Automated roll forming machines streamline these tasks by performing them in one continuous process. With minimal human intervention, manufacturers can significantly reduce labor costs while maintaining high production levels.

Automation also minimizes the risk of errors that often occur in manual operations, reducing waste and further saving costs. This allows companies to allocate their workforce more efficiently, focusing on higher-value tasks such as quality control and system optimization rather than routine manual labor.

One of the most significant advantages of automation in roll forming is the speed at which production can be completed. Automated machines can run continuously, producing metal drip edge at a much faster rate than manual methods. This increase in speed allows manufacturers to meet higher demand without compromising the quality of their products.

Modern roll forming machines are also designed to handle multiple operations at once, such as cutting, shaping, and punching. This eliminates the need for separate steps, further accelerating the production process. Manufacturers can quickly adapt to orders of various sizes and specifications, meeting deadlines more efficiently.

In the metal drip edge industry, product consistency is key to ensuring roofs are protected and function as intended. Automated roll forming machines are programmed to follow precise specifications, resulting in a uniform product across every batch. This consistency is particularly important for roofing contractors, as any deviation in product quality can lead to installation challenges and future maintenance issues.

Automated systems reduce the likelihood of defects, ensuring that each piece of drip edge meets the required dimensional tolerances and quality standards. This not only strengthens the manufacturer’s reputation but also helps them avoid costly returns and rework.

Automation is transforming the way metal drip edge is manufactured, with roll forming machines at the heart of this shift. By reducing labor costs, increasing production speed, and ensuring product consistency, manufacturers can enhance their competitiveness in the roofing industry. As technology continues to evolve, automation in roll forming is set to become even more integral to the success of metal drip edge production, offering a faster, more efficient, and cost-effective way to meet growing demand.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.