The D Style Drip Edge is a specific type of drip edge profile used primarily for roofing applications to direct water away from the roof and fascia, protecting the underlying structure from water damage. It has a rounded or "D" shaped curve, giving it its name, which adds both a functional and aesthetic dimension to roofing systems.

This profile is often made from metal materials like aluminum, galvanized steel, or copper, and is commonly installed along the edges of roofs, particularly on flat or low-slope roofs. The D style is ideal for homes or buildings in areas with significant rainfall, as it helps channel water efficiently into gutters, reducing the risk of leaks or damage to the roof structure.

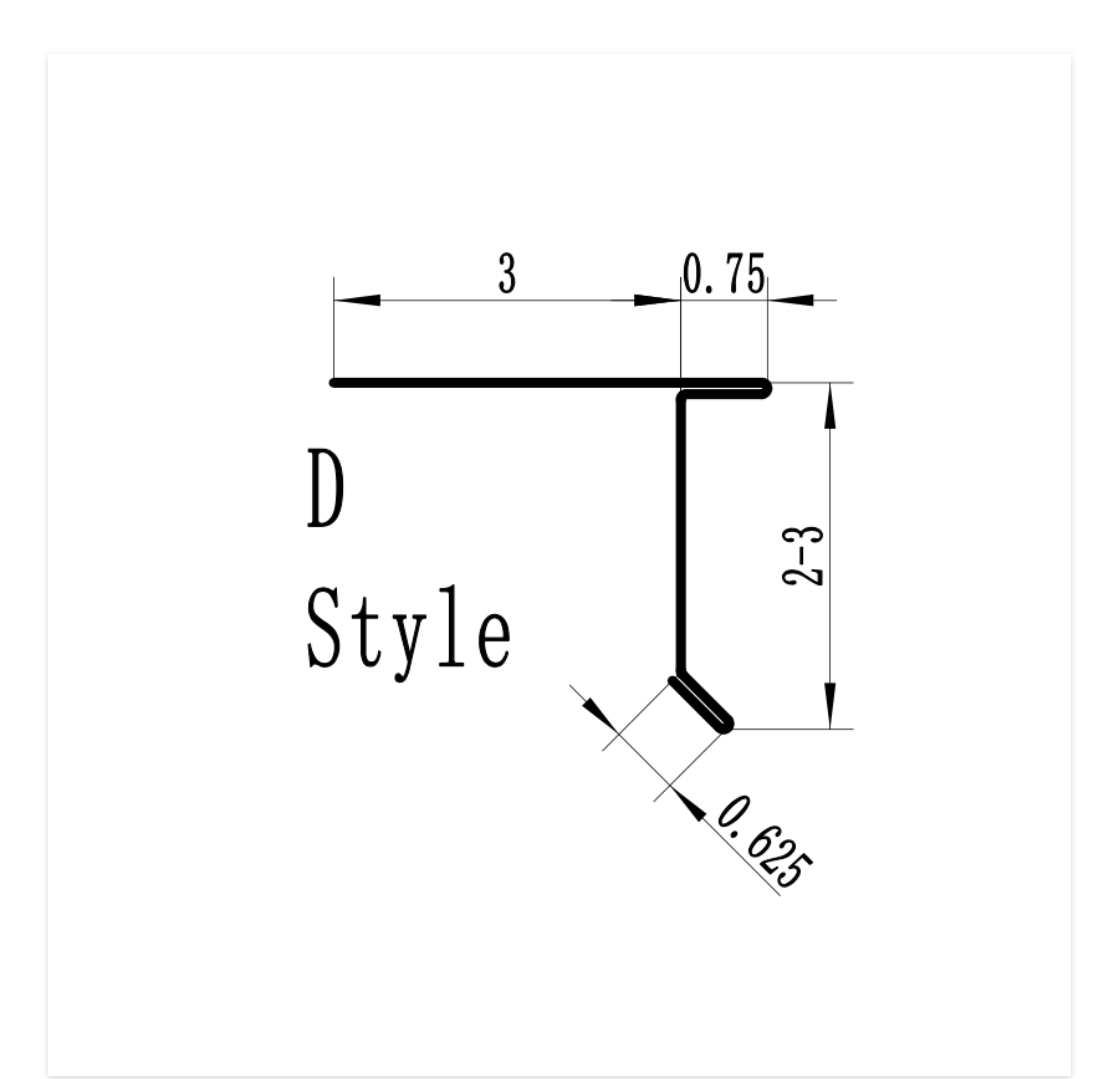

The D Style Drip Edge is a widely used drip edge profile due to its rounded top edge, which provides both structural benefits and a visually appealing finish. Below are some technical details and specifications for this profile:

1. Design Features:

- Shape: The “D” shape refers to the rounded curve at the top of the profile. This design allows for better water flow, directing rainwater away from the roof and into the gutter system.

- Flange: The vertical flange that attaches to the roof deck is typically flat and ranges in width from 1.5" to 3". This part is installed under the roofing material (shingles or underlayment), creating a seamless protective edge.

- Drip Leg: The extended bottom part is the drip leg, which is bent outward at a slight angle, allowing water to drip off the roof and away from the fascia, preventing water damage.

2. Materials:

- Aluminum: Lightweight and resistant to rust, making it suitable for various climates. Aluminum is often pre-painted or coated to match the roof or trim colors.

- Galvanized Steel: Durable and resistant to corrosion, especially when coated. Galvanized steel is common in commercial projects or areas with severe weather conditions.

- Copper: High-end option with a distinctive look. Copper drip edges are more expensive but offer extreme durability and a natural patina over time.

3. Common Dimensions:

- Face Width: 2" to 3" (the portion that extends over the fascia or gutter).

- Nailing Flange Width: Typically 1.5" to 3".

- Length: Typically comes in 10-foot lengths for ease of handling and installation, but can vary based on manufacturer specifications.

- Drip Leg Depth: Usually around 0.5" to 0.75" deep, allowing adequate space for water to run off.

4. Coatings and Finishes:

- Painted/Coated: Available in a variety of colors to match different roof styles. Pre-painted drip edges have a protective finish that helps extend their lifespan.

- Galvanization: For steel drip edges, a zinc coating is applied to resist rust and weather damage.

- Anodized: For aluminum versions, an anodized coating enhances durability and resistance to corrosion.

5. Installation:

- Placement: Installed at the edge of the roof, over the underlayment but under the shingles or roofing material. The drip leg should hang just over the fascia to guide water into the gutter.

- Fastening: Usually nailed or screwed into place along the roof edge with corrosion-resistant fasteners.

- Overlap: When installing, the edges of each drip edge piece should overlap by about 2" to ensure continuous protection along the roof edge.

6. Applications:

- Residential Roofing: Ideal for homes with shingle roofs or low-slope roof systems where water management is critical.

- Commercial Roofing: Used in flat or low-slope roofing systems for commercial buildings to ensure proper water run-off.

- Weather Protection: Common in areas with significant rainfall or snow as it helps prevent water from seeping under the shingles or into the roof deck.

7. Benefits:

- Water Management: Ensures rainwater flows directly into the gutter system, preventing water damage to fascia boards, soffits, and roof decking.

- Longevity: Extends the lifespan of the roof by protecting vulnerable edges from water infiltration.

- Aesthetic Appeal: The rounded design creates a smooth, finished look along the roofline.

8. Maintenance:

- Minimal Maintenance: Requires little maintenance, but periodic inspection is recommended to ensure the drip edge is intact, especially after severe weather events.

- Cleaning: Cleaning gutters and ensuring no debris accumulates around the drip edge will help maintain its functionality.

This profile is a versatile and important component for ensuring proper water shedding and protecting roofing structures. Would you like further details on specific materials or how it compares to other drip edge profiles?