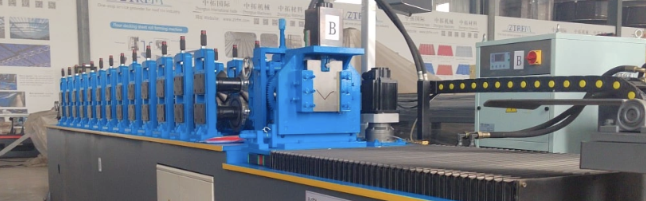

A flashing roll forming machine is specialized equipment used to manufacture metal flashing profiles for roofing and other building applications. These machines are designed to produce various types of metal flashing, such as step flashing, drip edge flashing, counter flashing, and other custom shapes, often from materials like aluminum, galvanized steel, and copper.

Key Features of a Flashing Roll Forming Machine:

- Customizable Profiles: Machines are often designed to produce specific flashing profiles like drip edge, valley flashing, step flashing, etc.

- Material Flexibility: They work with a variety of metals, including aluminum, galvanized steel, stainless steel, and copper, in different gauges.

- Adjustable Rollers: Most machines feature adjustable rollers to accommodate different flashing sizes and profiles without the need for extensive tooling changes.

- High Production Speed: These machines are designed for high-speed production, ensuring consistent quality and efficient output.

- Automatic Cutting: Many models come equipped with automatic cutting mechanisms that allow for precision cutting without manual intervention.

- CNC Control Systems: Modern machines often feature computerized controls for precise adjustments and ease of operation.

Applications:

- Roofing: Flashing for valleys, drip edges, step flashing, and other roof components.

- Building Construction: Flashing for windows, doors, and other exterior features to prevent water infiltration.

- Custom Flashing Profiles: The ability to produce flashing profiles tailored to specific construction projects.

Benefits:

- Efficiency: Produces large quantities of flashing consistently and quickly.

- Cost-effective: Reduces labor costs and waste by automating the production process.

- Precision: Ensures consistent, high-quality profiles with minimal variation.

Flashing profiles

Flashing profiles are essential components in construction, primarily used to prevent water infiltration at joints, edges, and intersections of roofs, walls, and other structural elements. They are designed to guide water away from critical areas, ensuring long-term durability and reducing the risk of leaks. Flashing profiles can be made from a variety of materials, including aluminum, galvanized steel, stainless steel, and copper.

Common Types of Flashing Profiles:

- Drip Edge Flashing:

- Purpose: Installed along the edges of a roof to prevent water from running underneath shingles and to protect the fascia.

- Profile: L-shaped or T-shaped with a small lip to divert water away from the roof edge.

- Step Flashing:

- Purpose: Used where the roof meets a vertical wall (e.g., chimneys or dormers). It is installed in layers, following the slope of the roof.

- Profile: Consists of small, rectangular pieces bent at a 90-degree angle.

- Valley Flashing:

- Purpose: Installed in roof valleys where two roof planes meet to direct water off the roof and into gutters.

- Profile: A wide, V-shaped or W-shaped profile.

- Counter Flashing:

- Purpose: Often used in combination with step flashing to cover and protect it, usually around chimneys or wall junctions.

- Profile: A horizontal or vertical flashing that covers the top of step flashing.

- Kickout Flashing:

- Purpose: Directs water away from the wall and into the gutter where a roof edge meets a vertical wall.

- Profile: Angled, with a small kick-out at the bottom.

- Z-Flashing:

- Purpose: Used to prevent water from penetrating vertical joints in siding or between other building materials.

- Profile: Shaped like a "Z," designed to overlap siding pieces or other materials.

- Base Flashing:

- Purpose: Installed at the base of a roof structure, typically around chimneys or vent pipes, to prevent water entry.

- Profile: Often used in conjunction with step flashing and designed to sit flat against the roof surface.

- Cap Flashing:

- Purpose: Installed over top of base flashing to provide additional protection against water.

- Profile: Typically has a horizontal bend that sits over the base flashing.

- Window and Door Flashing:

- Purpose: Prevents water infiltration around windows and doors.

- Profile: Can be L-shaped or flat with custom bends to suit the window or door frames.

Materials Used for Flashing:

- Aluminum: Lightweight, corrosion-resistant, and easy to work with.

- Galvanized Steel: Strong and durable, with a zinc coating for corrosion resistance.

- Copper: High durability and a traditional aesthetic, often used in premium projects.

- Lead: Malleable and highly durable but less commonly used due to environmental concerns.

These flashing profiles are crucial in preventing water damage, and their design varies depending on the specific application. If you're looking for specific profiles for a project or need further information on sourcing, feel free to ask!

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.