Posted on Thursday, September 26, 2024

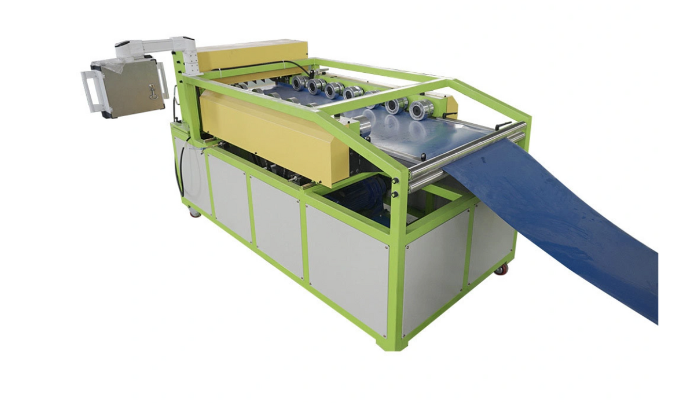

In today’s fast-paced construction world, contractors face increasing pressure to meet tight deadlines, reduce costs, and adapt to ever-changing project requirements. One solution that has emerged as a game-changer is the mobile roll forming machine. These versatile machines allow contractors to bring the power of roll forming directly to the job site, offering unparalleled flexibility, precision, and efficiency.

This blog will explore how mobile roll forming machines are revolutionizing construction processes, particularly for roofing and siding projects, and why they’re becoming an indispensable tool for contractors looking to maximize productivity.

One of the key advantages of mobile roll forming machines is the ability to produce panels and metal components on-site. In traditional manufacturing, roll-formed metal panels are produced in factories and then transported to the construction site, which can add significant time and cost to a project. Mobile roll forming machines eliminate these delays by enabling contractors to create custom-length panels right where they’re needed.

This on-site production capability has several advantages:

Despite the portability of mobile roll forming machines, they offer the same level of precision and consistency as their stationary factory counterparts. These machines are designed to meet the strict standards required in construction, ensuring that the quality of the panels produced on-site is indistinguishable from factory-made alternatives.

Whether you’re producing standing seam roofing panels, metal siding, or other components, mobile roll forming machines guarantee:

One of the standout features of mobile roll forming machines is their flexibility. On-site production enables contractors to quickly adapt to changing project requirements. If a project specification changes mid-construction, the contractor can adjust the machine’s settings and immediately start producing the new panel design or length.

This adaptability offers several key advantages:

Tight deadlines are a constant challenge in construction. Mobile roll forming machines enable contractors to speed up production and meet these deadlines without sacrificing quality. By producing panels on-site, contractors can bypass the traditional supply chain and manufacturing delays that often slow down projects.

The efficiency of mobile roll forming machines comes from:

Mobile roll forming machines are particularly suited to a range of construction applications. Some of the most common uses include:

Mobile roll forming machines are quickly gaining popularity across a wide range of construction industries, from roofing to commercial building. Their ability to produce high-quality metal components on-site, in real time, offers several key benefits that contractors are finding hard to ignore.

Mobile roll forming machines are transforming how contractors approach construction projects by bringing precision, flexibility, and efficiency directly to the job site. As the demand for faster project completion and more custom solutions continues to grow, these machines will become increasingly vital tools in the contractor’s toolkit.

For any contractor looking to stay ahead of the competition, mobile roll forming solutions offer an excellent way to streamline workflows, reduce costs, and deliver high-quality results—whether you’re working on a roofing project, producing siding, or tackling a challenging remote build. As the construction industry evolves, mobile roll forming machines are poised to play an even bigger role in shaping the future of on-site production.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.