Posted on Wednesday, September 18, 2024

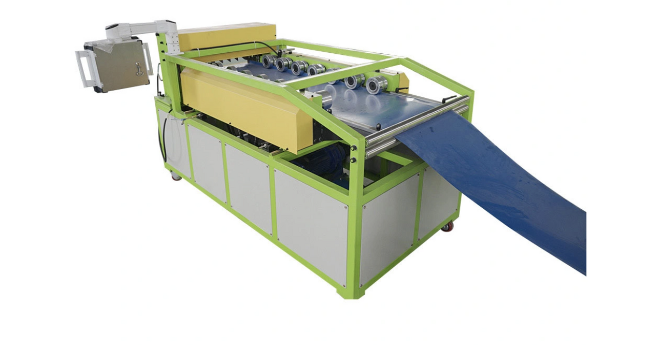

For a roll forming machine to produce snaplock standing seam panels in the United States, you would typically look for equipment that specializes in creating interlocking metal panels designed for roofing and siding. These machines allow the formation of precise standing seams without additional fasteners, which are popular for their sleek appearance and strong weather resistance.

Several manufacturers in the U.S. provide these machines, and it's important to consider the profile dimensions, material thickness, and width capabilities depending on your project requirements. Would you like specific recommendations or more details on suppliers?

snaplock standing seam panel

A snaplock standing seam panel is a type of metal roofing panel system designed for easy installation without the need for mechanical seaming tools. It is characterized by its interlocking edges that "snap" together to create a clean, durable standing seam. These panels are widely used in residential and commercial roofing due to their sleek appearance, watertight qualities, and ease of installation compared to traditional mechanical lock standing seam systems.

Key features of snaplock standing seam panels include:

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.