Here's a quick overview of popular machines:

- Standing Seam Roll Forming Machines:

- Ideal for producing standing seam roofing panels like Snaplock, mechanically seamed panels, and others.

- PBR Panel Roll Forming Machines:

- Used for creating PBR panels commonly seen in metal roofing systems.

- Corrugated Roofing Sheet Roll Forming Machines:

- Designed to produce traditional corrugated roofing sheets.

- Snaplock Standing Seam Roll Forming Machines:

- Tailored for the Snaplock panel system, which is a popular choice for residential and commercial roofing due to its easy installation process.

- Custom Roll Forming Machines:

- Many manufacturers offer customization based on the specific profiles you need, allowing for tailored designs for metal roofing applications.

A roofing sheet roll forming machine is used to manufacture metal roofing sheets by continuously bending metal coils into specific profiles for various types of roofing. Here are some common types of roofing sheet roll forming machines:

1. Standing Seam Roll Forming Machine:

- Produces standing seam metal roofing panels, which are widely used for both commercial and residential roofing applications due to their durability and sleek appearance. This type includes models like Snaplock, mechanically seamed, and batten seam.

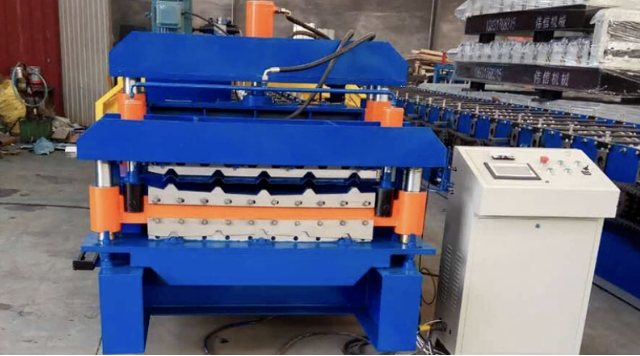

2. Corrugated Roll Forming Machine:

- Creates traditional corrugated metal roofing sheets, known for their wavy design. These sheets are lightweight, strong, and often used for agricultural or industrial buildings.

3. PBR Panel Roll Forming Machine:

- Used to produce PBR (Purlin Bearing Rib) panels. These panels are popular for metal building structures because they provide excellent strength and load-bearing capacity.

4. Tile Roof Sheet Roll Forming Machine:

- This machine manufactures metal roofing sheets that mimic the appearance of traditional clay or concrete tiles, providing a durable and lightweight alternative.

5. Trapezoidal Roof Panel Roll Forming Machine:

- This machine is used for creating trapezoidal roofing sheets, known for their high strength and modern look. It is widely used for commercial and industrial roofing systems.

6. Snaplock Standing Seam Roll Forming Machine:

- Specialized for producing Snaplock panels, which are a specific type of standing seam roofing that can be installed without mechanical seaming, making the installation process simpler and faster.

Key Features:

- Decoiler/Uncoiler: Feeds the metal coil into the roll forming system.

- Rollers: Series of rollers gradually shape the metal into the desired roofing profile.

- Cutting System: Some machines come with automatic cutting systems to size the sheets.

- Control Panel: Often computer-controlled (CNC) for precise dimensions and configurations.

These machines can be customized to produce different roof profiles based on regional needs and preferences.

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.