Posted on Tuesday, September 24, 2024

The roofing industry is experiencing a transformative shift, driven by advancements in technology, increased focus on sustainability, and evolving architectural trends. Among the many roofing solutions available today, Snaplock standing seam panels are emerging as a game-changer, setting new standards for performance, aesthetics, and durability.

Sustainability is no longer optional in the construction industry. Homeowners and businesses alike are seeking roofing solutions that reduce environmental impact and improve energy efficiency. Reflective metal roofing, solar panel integration, and recyclable materials are becoming critical components of modern roofing designs. Snaplock panels, made from durable metals like aluminum or steel, align perfectly with these demands due to their recyclability and energy-efficient properties.

Extreme weather conditions, from hurricanes to heavy snowfall, have increased the demand for roofing materials that offer unparalleled durability. Standing seam metal panels, including Snaplock, are known for their ability to withstand harsh elements, resist corrosion, and last significantly longer than traditional roofing options like asphalt shingles.

Modern architectural designs emphasize clean lines and minimalistic aesthetics. Snaplock standing seam panels complement this trend, offering a sleek and sophisticated look without exposed fasteners, making them ideal for contemporary residential and commercial buildings.

The construction industry faces labor shortages and tight deadlines. Roofing materials that are easier and faster to install are becoming increasingly popular. Snaplock panels simplify installation compared to traditional standing seam systems by eliminating the need for special tools or mechanical seaming, making them a practical choice for contractors.

Snaplock panels are designed with pre-fabricated edges that securely "snap" together, creating a watertight seal. This design not only enhances structural integrity but also reduces the risk of leaks, making them highly reliable in areas prone to heavy rain or snow.

Snaplock panels can accommodate reflective coatings that help regulate indoor temperatures by reflecting sunlight, reducing cooling costs in hot climates. Additionally, they can be easily integrated with solar panels, aligning with green building initiatives.

Snaplock panels are available in various materials, finishes, and colors, providing architects and builders with endless design possibilities. Whether it’s a sleek metallic finish for a modern home or a bold color for a commercial property, Snaplock panels offer unmatched versatility.

Compared to other roofing systems, Snaplock panels require minimal maintenance. Their hidden fasteners reduce the likelihood of wear and tear, while their durable materials resist rust and corrosion, ensuring long-term cost savings.

Modern homeowners prioritize comfort, and metal roofing systems like Snaplock standing seam panels are designed to reduce noise during rain or hailstorms, thanks to advanced underlayment and panel designs.

The combination of durability, aesthetic appeal, and cost-effectiveness positions Snaplock panels as a leading choice in modern roofing. They meet the needs of both contractors and property owners by offering:

As the construction and roofing industries continue to evolve, Snaplock standing seam panels are setting themselves apart as an industry favorite. They seamlessly blend performance, aesthetics, and sustainability, making them a top choice for builders and property owners seeking modern roofing solutions. By aligning with trends like energy efficiency, durability, and sleek designs, Snaplock panels represent the future of roofing—one that prioritizes both form and function.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

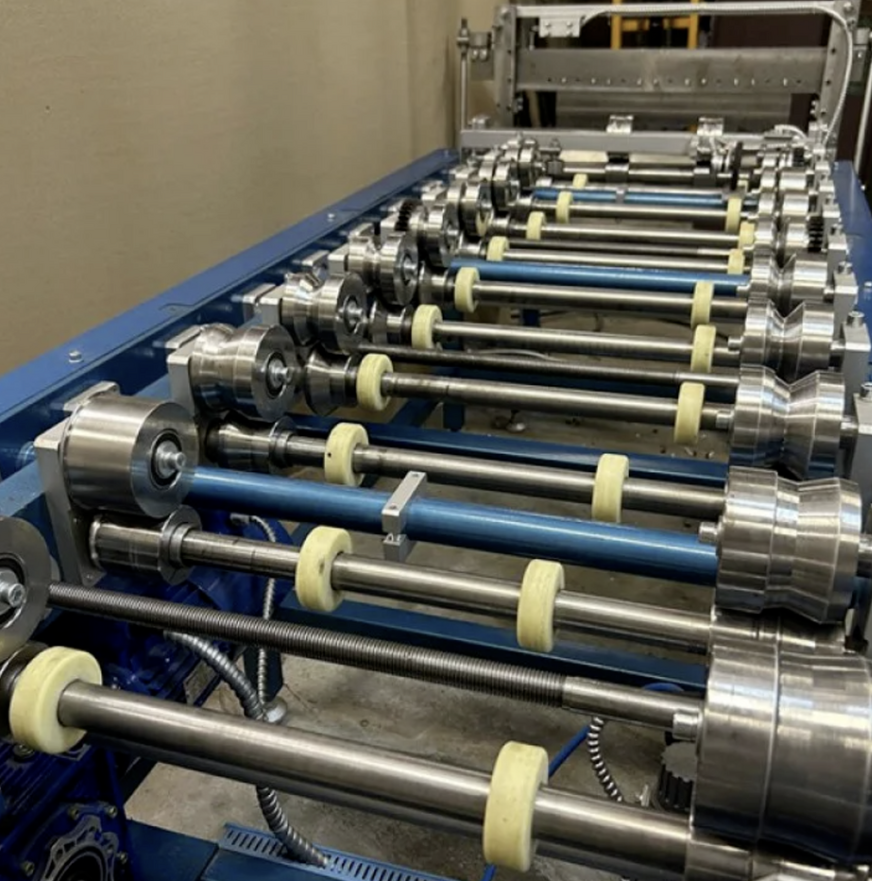

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.