Posted on Monday, September 30, 2024

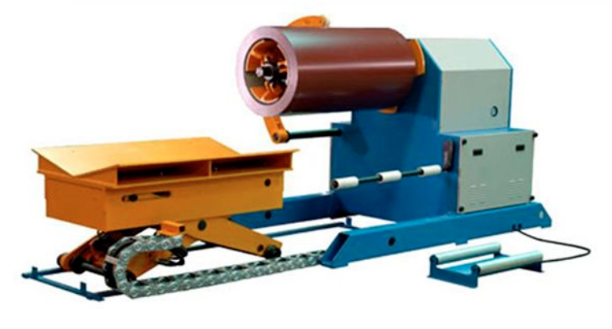

An uncoiler is an essential machine in the roll forming process, responsible for feeding metal coils into the roll forming line. The uncoiler holds and unwinds large coils of metal (such as steel, aluminum, or copper), preparing them to be shaped into specific profiles by the roll forming machine. It is the first stage in the production process, and its smooth operation is critical for maintaining the continuous flow of material.

In summary, an uncoiler plays a vital role in ensuring that the roll forming line operates efficiently, reducing downtime and enhancing the overall quality of the finished product.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.