Posted on Monday, September 30, 2024

Roll forming machines are vital tools in industries such as construction, automotive, and manufacturing. These machines shape metal into precise profiles used for roofing, framing, and more. While the core purpose of roll forming machines is the same across the globe, the designs and technologies vary based on regional preferences and industry demands. Two major regions leading in roll forming machinery are Europe and the United States. In this blog, we will explore the key differences between European and U.S. roll forming machines, highlighting design variations, technological innovations, and market preferences.

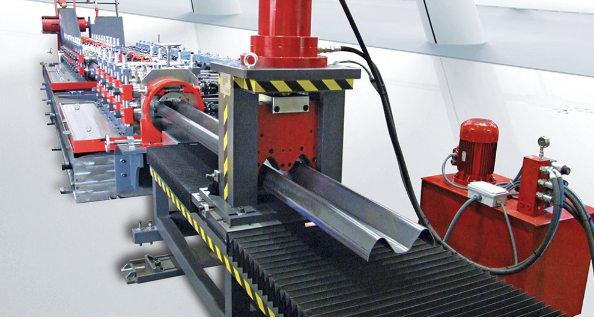

European Roll Forming Machines

European roll forming machines are known for their compact and modular designs. Manufacturers in Europe prioritize flexibility and precision, often catering to industries that require complex and intricate profiles. Due to space constraints in many European manufacturing facilities, these machines are typically more streamlined, maximizing efficiency within smaller production spaces. This focus on compactness makes European machines ideal for high-precision applications where space and flexibility are crucial.

U.S. Roll Forming Machines

In contrast, U.S. roll forming machines are often larger and built for heavy-duty production. U.S. industries, especially in construction, automotive, and steel manufacturing, demand machines capable of handling high volumes over extended periods. As a result, U.S. machines tend to prioritize durability, strength, and throughput. They are designed to operate in large-scale production facilities where space is less of a concern, and the focus is on mass production.

Europe

Europe leads the way in adopting advanced automation technologies and energy-efficient solutions. Many European roll forming machines are integrated with Industry 4.0 technologies, allowing for smart production lines with automated controls, real-time data analysis, and precise adjustments to ensure optimal performance. This focus on automation allows for high-precision manufacturing, reducing human error and making European machines highly efficient in complex, high-precision applications.

European manufacturers also emphasize sustainability, with many machines designed to consume less energy while maintaining peak performance. This emphasis on eco-friendly manufacturing aligns with Europe’s broader push for greener industrial practices.

United States

In the U.S., technology advancements often focus on increasing production speed and output. U.S. machines are designed for industries that need to meet large-scale demands, such as commercial construction and automotive manufacturing. While automation is certainly a part of modern U.S. machines, the focus tends to be on boosting production capacity, enabling manufacturers to meet tight deadlines for large infrastructure projects.

U.S. manufacturers also prioritize ruggedness in their machines. The ability to perform consistently under high-stress conditions and continuous operation is a hallmark of U.S. roll forming equipment, making these machines suitable for demanding environments where uptime and high output are critical.

European Market

The European market tends to favor highly specialized, customized machines tailored to specific industry needs. This reflects Europe’s diversity of architectural styles and manufacturing sectors. European manufacturers are often willing to invest more upfront in machinery that delivers long-term precision, reliability, and energy efficiency. This preference for specialized equipment is driven by smaller, more niche manufacturing operations that need to meet specific requirements rather than mass production.

U.S. Market

In the U.S., the market leans towards machines that offer versatility and can handle a wide range of applications. U.S. manufacturers often prioritize cost-effectiveness, and the ability to adapt machines for various projects without extensive modifications is highly valued. The demand for machines that can quickly switch between different profiles and deliver high-volume production at lower operating costs is a key characteristic of the U.S. market, where industries like construction and automotive rely on fast, efficient production processes.

European Customization

Customization is a significant focus for European roll forming machine manufacturers. Many European companies operate in industries that require specialized equipment capable of producing unique profiles. Whether it’s for custom architectural features, automotive parts, or small-batch production, European roll forming machines are often tailored to meet the specific needs of each project. This makes European machines highly valued in markets where precision and adaptability are critical.

U.S. Standardization

In contrast, the U.S. market tends to favor standardization. U.S. roll forming machines are often built to handle a wide range of profiles with minimal adjustments, making them suitable for mass production. This versatility allows U.S. manufacturers to use the same machine for different projects, reducing the need for frequent retooling. Standardization helps manufacturers lower costs and increase efficiency, especially in industries where large-scale production is the norm.

Europe

While European machines are often more compact and flexible, they excel in precision rather than raw production speed. However, with the integration of advanced automation technologies, European machines can still operate efficiently, especially in industries that require small-batch, high-precision production. The focus is often on delivering consistent quality while minimizing waste, energy consumption, and downtime.

United States

U.S. roll forming machines are built for speed and efficiency, often running at high capacity for large-scale construction and manufacturing projects. Production speed is a key factor, and U.S. machines are designed to handle continuous operation with minimal downtime. This makes them ideal for industries where high-volume output is essential, such as roofing, automotive manufacturing, and large-scale infrastructure projects.

While both European and U.S. roll forming machines offer cutting-edge technology and robust performance, the choice between them ultimately depends on the specific needs of the manufacturer and the market. European machines emphasize precision, flexibility, and sustainability, making them ideal for specialized industries and smaller production spaces. U.S. machines, on the other hand, prioritize durability, high-volume production, and versatility, making them better suited for large-scale projects with high throughput demands.

Whether you need a machine tailored for small-batch, high-precision work or a robust solution for high-speed mass production, understanding the regional differences can help you make an informed choice that best suits your production requirements.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.