A 90-degree style drip edge helps direct water away from the edge of the roof and into the gutters, preventing water damage to the roof deck and underlying structure.

This type of drip edge typically features:

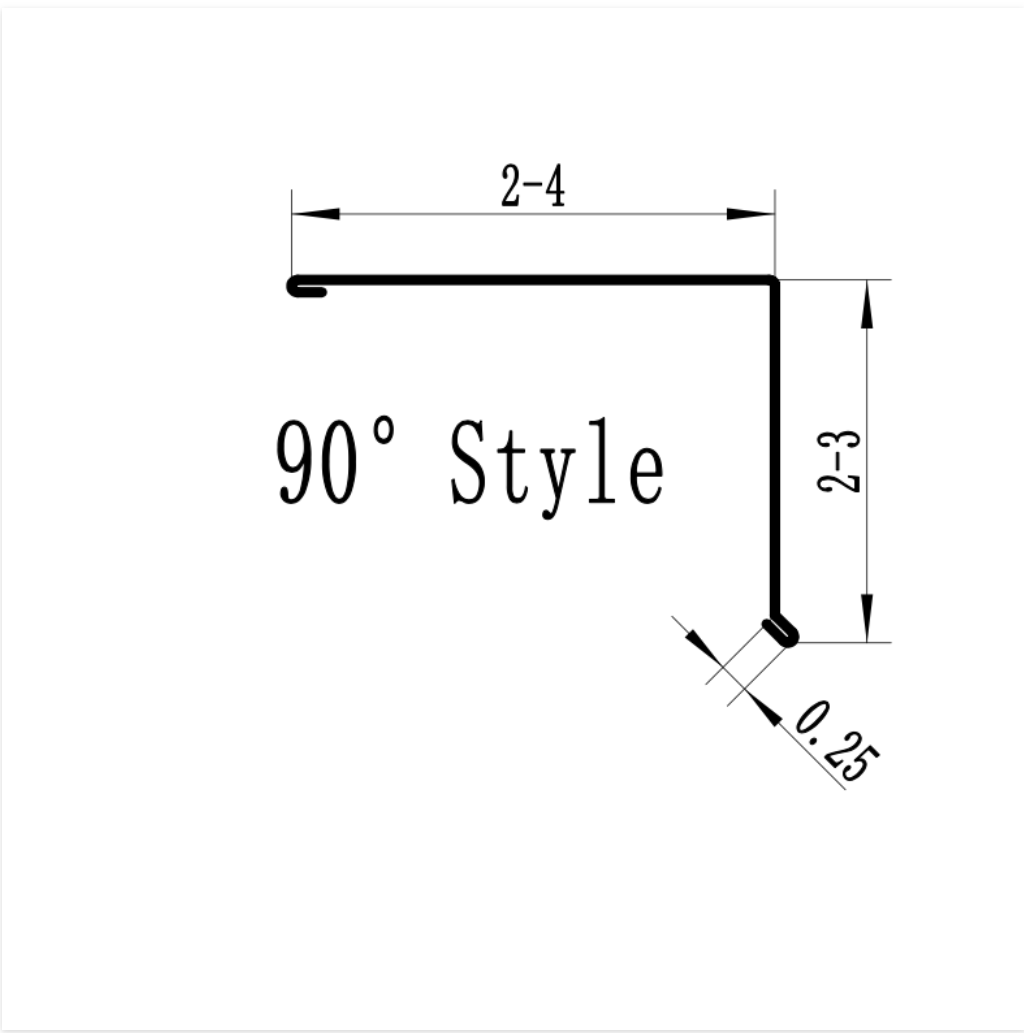

- A 90-degree bend, creating a clean, straight corner that aligns with the roof's edge.

- A bottom lip that extends outward slightly, allowing water to drip off the edge instead of clinging to the surface.

- It is usually made from metal, such as aluminum, galvanized steel, or copper, to ensure durability and weather resistance.

It is often used in residential and commercial roofing applications, particularly where a crisp, angular appearance is desired for aesthetic and functional purposes.

A roll forming machine that produces a 90-degree style drip edge profile is a specialized piece of equipment designed to continuously shape metal coils into the desired drip edge profile through a series of precisely positioned rollers. Here's a breakdown of how it works and the machine's capabilities:

Features of a Roll Forming Machine for 90-Degree Drip Edge Profile

- Material Compatibility:

- The machine can work with various materials like aluminum, galvanized steel, copper, or other metals commonly used in roofing.

- It can handle coils in different thicknesses, typically ranging from 0.2 mm to 1.0 mm, depending on the specific requirements of the drip edge.

- Customizable Profiles:

- The machine can be adjusted to create various drip edge profiles, including different angles (such as 90-degree, 45-degree, etc.) and customizations like bottom lips for water runoff.

- Lengths can be customized as well, allowing manufacturers to produce drip edge in precise lengths according to project specifications.

- High Production Speed:

- Roll forming machines are known for their efficiency, producing drip edge profiles in large quantities at high speed with minimal manual intervention.

- Speeds can vary depending on the machine model but typically range between 10 to 30 meters per minute, making it suitable for high-volume production.

- Precision and Consistency:

- Roll forming machines are designed to produce highly accurate and consistent profiles with every pass. The rollers gradually shape the metal to ensure there are no deformities, ensuring perfect 90-degree angles for drip edges.

- The machine's computerized control system ensures each part is identical, reducing errors and material waste.

- Cutting System:

- The machine often comes equipped with a cutting unit (either hydraulic or pneumatic) that can automatically cut the drip edge to the desired length without interrupting the production process. This can be done on-the-fly or at set intervals.

- Automatic and Manual Controls:

- Advanced machines are typically CNC-controlled, allowing for easy setup and adjustment through digital interfaces. Operators can input custom parameters to adjust the profile's size, angle, and length.

- Manual adjustments can also be made for fine-tuning, making it versatile for both custom and standard drip edge profiles.

- Coil Feeding and Uncoiling Systems:

- A key component is the uncoiler/decoiler, which automatically feeds the metal coil into the machine. This ensures a smooth and continuous operation, minimizing downtime and maximizing production efficiency.

Benefits of a Roll Forming Machine for Drip Edge Profiles

- Efficiency and Speed: Continuous production allows manufacturers to meet high demand for drip edges without sacrificing quality or consistency.

- Versatility: These machines can create various styles of drip edges (including 90-degree) by adjusting the rollers and angles, allowing for custom designs as needed.

- Cost Savings: The roll forming process minimizes material waste, reduces labor costs due to automation, and ensures precise cutting for optimal material usage.

- Durability: The machine is built to handle tough materials like galvanized steel and copper, making it a durable solution for producing metal roofing components.

Key Industries for This Machine

- Roofing Contractors: Primarily used by manufacturers supplying roofing components to residential and commercial building projects.

- Metal Fabricators: Companies specializing in producing custom metal roofing accessories often use these machines for various roofing profiles, including drip edges.

- Construction Suppliers: These machines are key for large-scale production of standard drip edge profiles distributed to construction projects.

In conclusion, a roll forming machine designed for a 90-degree drip edge profile is a powerful tool for roofing manufacturers and suppliers, enabling them to produce high-quality, consistent, and customizable profiles efficiently.