Posted on Thursday, October 3, 2024

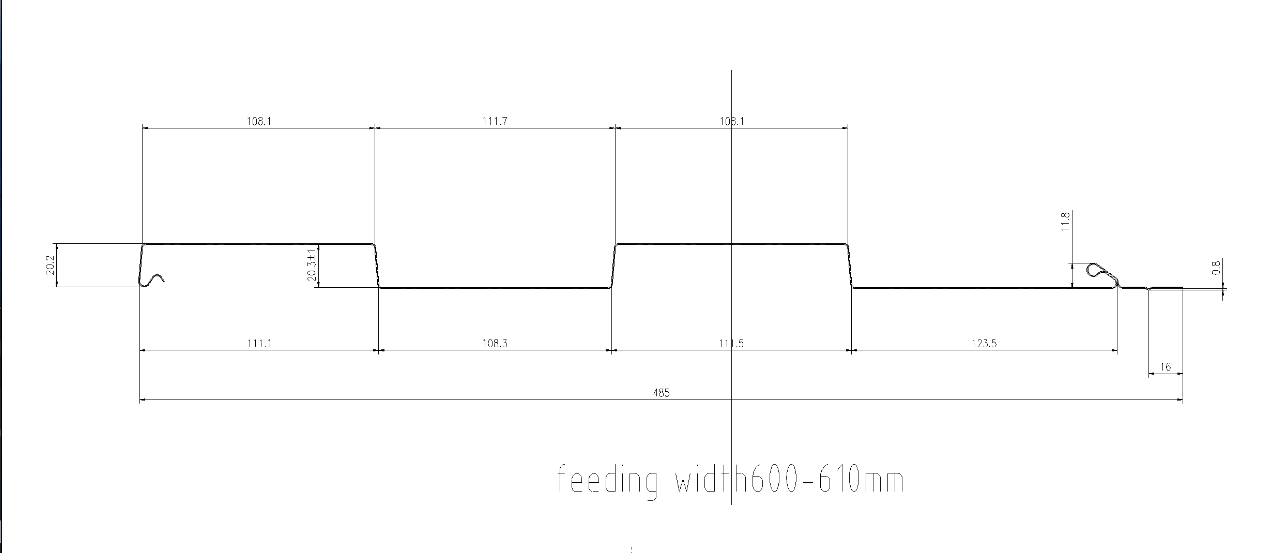

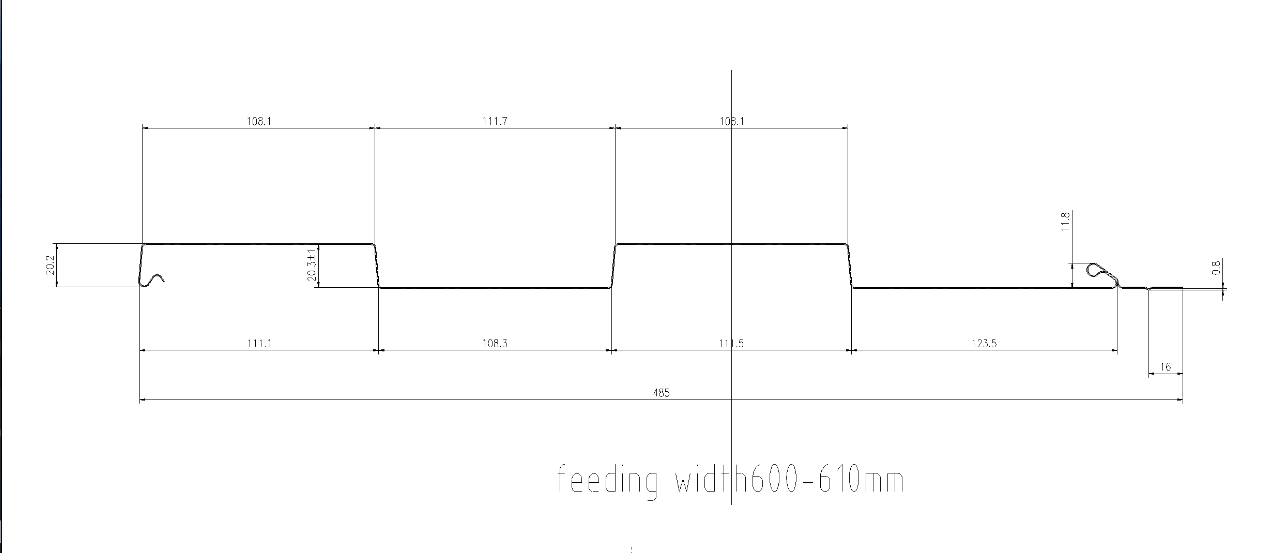

The Box Rib Wall Panel Roll Forming Machine is designed to produce high-strength, durable wall panels with a distinctive box rib profile, ideal for industrial, commercial, and agricultural buildings. These panels offer excellent structural performance and aesthetic appeal, making them popular in modern construction. The machine forms metal sheets into precise box rib profiles, ensuring consistency in panel design, strength, and weather resistance.

Key features:

Box rib wall panels are commonly used for siding, cladding, and roofing applications, providing a balance of durability, weather resistance, and aesthetics.

The Box Rib Wall Panel Profile is characterized by its bold, square-shaped ribs that provide both strength and visual appeal. This profile is commonly used in commercial, industrial, and agricultural buildings for wall cladding and sometimes roofing. The ribs enhance the panel's load-bearing capacity, making it suitable for both structural and non-structural applications. The design also offers improved resistance to wind and water, making it a durable option for exterior use.

The Box Rib Wall Panel Profile is a versatile, long-lasting solution that combines aesthetic appeal with functional performance, making it a popular choice in various construction projects.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.