Posted on Monday, October 7, 2024

In the ever-evolving landscape of the Canadian construction industry, selecting the right roll forming machine is crucial for contractors and erectors looking to stay competitive. With diverse regional demands, stringent compliance regulations, and technological advancements, making an informed choice can significantly impact project success. This blog aims to provide practical tips for contractors in Canada on how to choose the right roll forming machine to meet their unique needs.

Canada's construction market is characterized by varying demands across regions. From high-rise commercial buildings in urban centers like Toronto to residential developments in suburban areas, understanding the local market's needs is essential. Contractors should analyze:

Canada has a robust framework of building codes and regulations that govern construction practices. It is vital for contractors to familiarize themselves with local compliance requirements, as this can affect both machine selection and project execution. Consider the following:

Canada's construction industry commonly uses steel and aluminum, each with distinct properties and processing requirements. Ensure that the machine you select can handle the specific materials relevant to your projects.

Assess your expected production volume. A higher production volume may necessitate a machine with greater capacity and speed, while smaller operations may benefit from more compact, versatile options. Consider your workflow and the types of projects you typically handle.

In a competitive market, the ability to produce custom profiles can set you apart. Evaluate whether the machine can accommodate various designs and specifications, enabling you to meet diverse client needs.

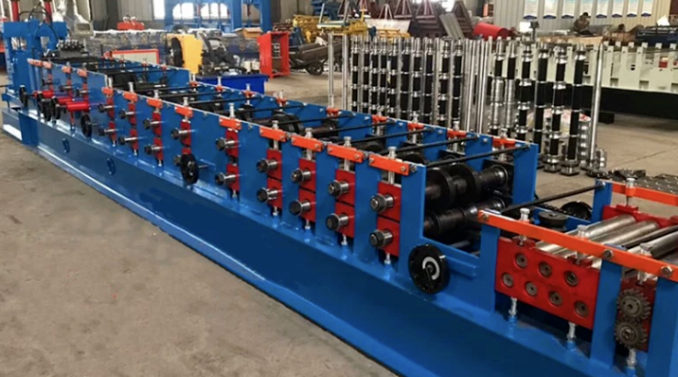

Modern roll forming machines come equipped with advanced features that enhance productivity and ease of use. Look for machines with automation capabilities, user-friendly interfaces, and precise control systems that can streamline operations and minimize manual labor.

Reliable support and maintenance options are crucial for minimizing downtime. Investigate the availability of local service technicians and spare parts to ensure that your machine operates smoothly and efficiently throughout its lifecycle.

Balancing cost with quality and capability is essential when selecting a roll forming machine. Establish a clear budget that includes not only the initial purchase price but also ongoing operational costs such as maintenance, energy consumption, and potential upgrades. Additionally, explore financing options available for contractors in Canada, as many manufacturers offer flexible payment plans to facilitate your investment.

Choosing the right roll forming machine is a strategic decision that can influence your project's success and your business's competitiveness in the Canadian market. By understanding local demand, complying with regulations, and carefully considering key factors such as material compatibility and technological features, contractors can make informed decisions that align with their operational needs.

In an industry where precision and efficiency are paramount, taking the time to evaluate your options thoroughly is crucial. Don’t hesitate to seek expert advice or reach out for personalized recommendations to help guide your decision-making process.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.