Posted on Wednesday, October 9, 2024

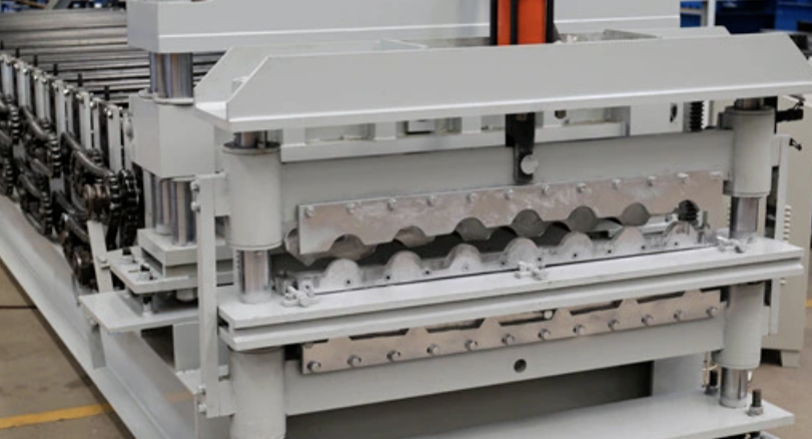

In the diverse landscape of global construction and manufacturing, the demand for specialized solutions is on the rise. At MachineMatcher, we understand that different regions have unique requirements, influenced by factors such as local building codes, environmental conditions, and industry standards. Our custom roll forming machines are designed to meet these specific needs, ensuring that manufacturers can produce tailored products that cater to their markets.

One of the most significant applications of our custom roll forming machines is in the production of unique roofing profiles. Different regions often have preferred styles and materials for roofing, influenced by local climate, aesthetics, and building regulations. For instance, areas prone to heavy rainfall may require roll forming machines that produce roofing profiles with enhanced drainage capabilities. In contrast, regions with high temperatures may benefit from profiles designed for better thermal efficiency. Our team works closely with clients to understand their specific requirements and design machines that produce these tailored profiles efficiently.

The industrial construction sector also presents unique challenges that our custom roll forming solutions address. Different industries, from automotive to aerospace, require specific metal components that meet stringent performance standards. MachineMatcher’s ability to create bespoke roll forming machines allows manufacturers to produce components with precise dimensions and tolerances, essential for applications such as structural supports, frames, and panels. By integrating the latest technology into our designs, we ensure that these machines are not only efficient but also capable of adapting to evolving industry needs.

As the world shifts towards sustainable energy solutions, the demand for customized roll forming machines in renewable energy projects has increased. Whether it’s producing solar panel mounting systems or wind turbine components, MachineMatcher designs machines that facilitate the efficient production of these critical parts. Our expertise allows us to tailor machinery to handle the unique specifications required for renewable energy applications, helping clients contribute to the global sustainability movement.

Custom roll forming machines from MachineMatcher are not just about machinery; they represent a commitment to understanding and meeting the diverse needs of global markets. By collaborating with our clients to create tailored solutions for roofing, industrial construction, and renewable energy projects, we empower manufacturers to thrive in their respective industries. Our focus on customization ensures that each machine we design is perfectly aligned with the specific requirements of the region, enhancing efficiency, quality, and ultimately, competitiveness in the global marketplace.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.