Posted on Thursday, October 31, 2024

In today's competitive manufacturing landscape, every edge counts. For Hungarian manufacturers, investing in the right machinery can mean the difference between barely breaking even and achieving record-setting efficiency and profitability. This case study explores the journey of Kovács Metalworks, a mid-sized Hungarian manufacturer specializing in metal components for the construction and automotive industries, as they transformed their production with a strategic upgrade to their roll forming machinery.

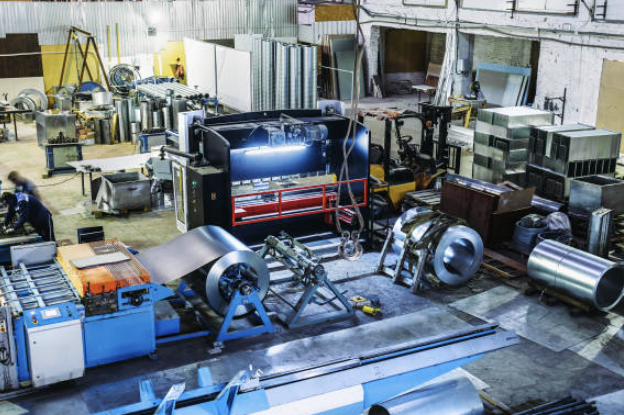

Kovács Metalworks had been facing rapid growth in demand for customized metal profiles. While demand is always a good problem to have, Kovács's existing equipment struggled to keep pace. Their older roll forming machine, purchased nearly a decade ago, required frequent repairs, limited production to a narrow range of profiles, and lacked the flexibility necessary for today’s highly customized orders. Additionally, the machine's lower production speed made it difficult to meet growing customer demands, leading to longer lead times and, ultimately, customer dissatisfaction.

The main challenges faced were:

Kovács Metalworks decided it was time to upgrade. After consulting with industry experts, they chose a modern, fully automated roll forming machine tailored to their specific needs. The new machine provided increased versatility, allowing Kovács to quickly switch between profiles with minimal downtime. Additionally, its advanced software made it easier to adjust settings for highly customized orders, a key advantage for meeting the diverse needs of Hungary’s booming construction and automotive industries.

The chosen machine included:

Once the machine was installed, Kovács’s production team underwent a thorough training program to familiarize themselves with the new equipment’s capabilities. Training was conducted by the equipment supplier, who tailored sessions to Kovács’s specific needs. This included instruction on handling the machine’s advanced software, profile adjustments, and basic troubleshooting techniques.

With only a few weeks of training, Kovács’s operators were able to make full use of the machine’s customizable features. The learning curve was manageable, and Kovács saw minimal downtime during the transition phase. The supplier’s comprehensive support ensured that Kovács’s team could smoothly implement the machine and transition to full-scale production quickly.

The impact of this upgrade was quickly evident. Within six months, Kovács Metalworks experienced remarkable improvements:

Kovács Metalworks’ investment in the new roll forming machine has transformed the company's operations, positioning them as a leader in custom metal profiles in Hungary. The upgrade has allowed them to not only meet but exceed customer expectations, ensuring a competitive edge in a challenging market.

Key Takeaways for Other Hungarian Manufacturers:

For Kovács Metalworks, upgrading to a modern roll forming machine was a strategic move that transformed their business operations. By embracing modern technology and training their team, they not only boosted production efficiency but also increased their market reach. Hungarian manufacturers looking to stay competitive can learn from Kovács's experience, illustrating that the right investment in technology can deliver unparalleled advantages in today’s dynamic market.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.