Here's a step-by-step guide:

Tools and Equipment Needed:

- New hydraulic hoses (ensure they are the correct size and rating)

- Wrenches (appropriate sizes for fittings)

- Oil spill mats or absorbent materials

- Hydraulic fluid

- Safety gloves and goggles

- Torque wrench (optional but recommended)

- Rags or towels for cleanup

Step-by-Step Process:

1. Turn Off the Machine and Release Pressure

- Power Off: Ensure the roll forming machine is completely powered off. Disconnect it from the electrical supply to prevent any accidental startups.

- Release Hydraulic Pressure: Bleed off any pressure in the hydraulic system by operating any valves or levers that can relieve the pressure within the system.

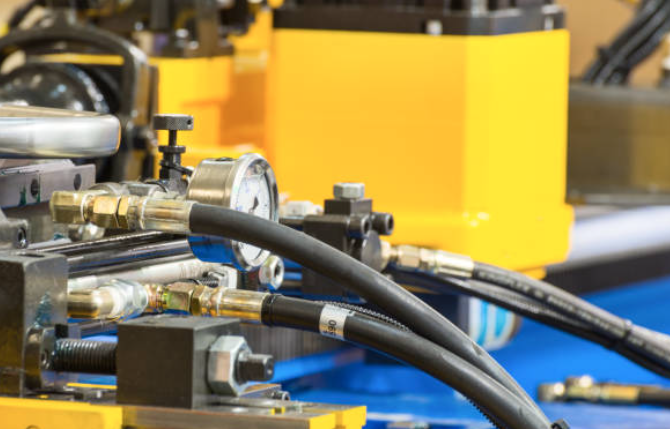

2. Locate the Hydraulic Hoses

- Identify the hoses you need to replace. Check the machine's manual to locate specific hoses and fittings, or follow the hydraulic system’s path to find them.

3. Prepare for Fluid Leaks

- Place oil spill mats or absorbent materials under the area where you’ll be working to catch any hydraulic fluid that leaks out when disconnecting the hoses.

4. Disconnect the Old Hoses

- Loosen Fittings: Use the correct-sized wrench to carefully loosen the fittings at both ends of the hydraulic hose. Be cautious, as some fluid may still be pressurized.

- Remove the Hose: Once the fittings are loosened, remove the old hose. Use rags to wipe any excess fluid from the fittings and surrounding areas.

5. Inspect the Fittings and Surroundings

- Check the hydraulic fittings and surrounding components for signs of wear, damage, or contamination. Clean the fittings thoroughly before attaching the new hose.

6. Install the New Hydraulic Hose

- Check Specifications: Ensure the new hose matches the specifications of the old one, including diameter, length, and pressure rating.

- Attach the New Hose: Attach one end of the hose to the appropriate fitting and hand-tighten the connection. Then use a wrench to secure the fitting, being careful not to over-tighten.

- Attach the Other End: Repeat the process for the other end of the hose, ensuring the hose is not twisted or kinked.

7. Tighten and Torque (if applicable)

- After both ends are connected, use a torque wrench to tighten the fittings to the manufacturer’s recommended torque value, if available. Over-tightening can damage the fittings or the hose.

8. Refill Hydraulic Fluid (if necessary)

- If any fluid was lost during the process, top off the hydraulic reservoir with the appropriate type of hydraulic fluid. Refer to the machine’s manual for the correct fluid specifications.

9. Test the System

- Power On the Machine: Once everything is connected, power on the roll forming machine.

- Test the Hydraulic System: Operate the hydraulic components to ensure the system is functioning correctly and that there are no leaks.

10. Check for Leaks

- Visually inspect the newly installed hose connections for any signs of fluid leakage. If leaks are found, re-tighten the fittings slightly and recheck.

11. Clean Up

- Wipe down any spilled hydraulic fluid and remove absorbent materials from the area.

By following these steps, you can safely change the hydraulic hoses on your roll forming machine while minimizing downtime and ensuring the system operates smoothly.