Posted on Monday, October 7, 2024

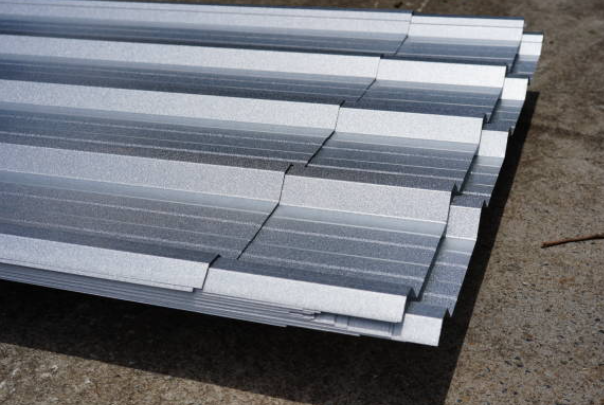

In the competitive landscape of the construction industry, steel deck manufacturers must continually seek ways to improve efficiency, reduce costs, and enhance product quality. One of the most impactful strategies for achieving these goals is investing in or upgrading roll forming machines. This blog delves into the financial benefits that steel deck manufacturers can achieve through such investments, highlighting how modern roll forming technology can maximize return on investment (ROI).

To appreciate the potential ROI of roll forming machines, it is essential to understand the cost structures involved in traditional manufacturing processes. Conventional methods often involve higher labor costs, significant material waste, and lower production speeds. In contrast, roll forming technology requires a higher initial investment but offers substantial long-term savings.

One of the most significant advantages of roll forming machines is their ability to increase production efficiency. These machines are designed to produce large quantities of steel decking quickly and with precision. For instance, manufacturers that have adopted modern roll forming technology report throughput increases of up to 50%. This enhanced efficiency allows companies to meet rising demand without compromising quality.

Another critical financial benefit of roll forming is the reduction in material waste. Traditional manufacturing processes can lead to significant scrap metal due to cutting and shaping techniques. Roll forming, however, uses continuous strips of metal, allowing manufacturers to optimize material use effectively. Studies indicate that companies utilizing roll forming technology can reduce material waste by 20% or more, translating directly into cost savings.

Automation plays a crucial role in modern roll forming systems, reducing the reliance on manual labor. Advanced roll forming machines can operate with minimal human intervention, which lowers labor costs significantly. Manufacturers that have invested in automated systems often see a reduction in labor costs by up to 30%, enhancing their overall profitability. Additionally, the reduced need for manual labor allows companies to allocate resources more effectively, focusing on higher-value tasks.

Quality control is paramount in the manufacturing of steel decking. Roll forming machines deliver high precision and consistency in product quality, which helps to minimize rework and scrap. When manufacturers produce high-quality products, they reduce the costs associated with returns and customer dissatisfaction. Enhanced quality can also open doors to premium pricing, further improving profit margins.

In today's market, energy efficiency is becoming increasingly important. Modern roll forming machines are engineered to consume less energy than older models. By investing in energy-efficient machinery, manufacturers can reduce their utility bills significantly over time. Some companies report energy savings of up to 40%, contributing to a lower cost of production and higher overall ROI.

Older roll forming machines often require more maintenance and are prone to breakdowns, leading to costly downtime. In contrast, new roll forming technology features improved reliability and requires less frequent maintenance. Manufacturers that transition to modern machinery typically experience reduced downtime, which can save thousands of dollars annually in lost production and repair costs.

Investing in advanced roll forming machines can position steel deck manufacturers as leaders in quality and efficiency. As customers increasingly demand quick turnaround times and custom solutions, the ability to deliver high-quality products quickly becomes a competitive advantage. Companies equipped with modern roll forming technology are better equipped to meet these demands, ensuring they remain relevant in a fast-paced market.

The construction industry is evolving, with trends such as sustainability and modular construction gaining traction. Roll forming machines can be quickly adjusted to produce a variety of profiles and designs, allowing manufacturers to respond rapidly to changing market needs. This adaptability can enhance a company's reputation and increase customer loyalty.

Several steel deck manufacturers have successfully maximized their ROI by investing in roll forming technology. For example, a leading steel deck manufacturer in the Midwest reported a 40% increase in production capacity and a 25% reduction in material waste after upgrading to a new roll forming line. Their improved efficiency and reduced costs translated into increased profits and market share.

Another company in the Southwest highlighted that their investment in automation not only reduced labor costs by 30% but also improved product quality, resulting in fewer returns and higher customer satisfaction.

Investing in or upgrading roll forming machines is a strategic move for steel deck manufacturers seeking to maximize their ROI. By enhancing production efficiency, reducing material waste, lowering labor costs, and improving product quality, these machines provide significant financial benefits. Additionally, the long-term advantages, such as energy efficiency and reduced downtime, make roll forming technology a smart investment for sustainable growth.

Manufacturers should evaluate their current operations and consider the advantages of modern roll forming technology. By making this investment, steel deck manufacturers can secure their position in the industry, increase profitability, and ultimately contribute to the success of their businesses.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.