Posted on Sunday, October 6, 2024

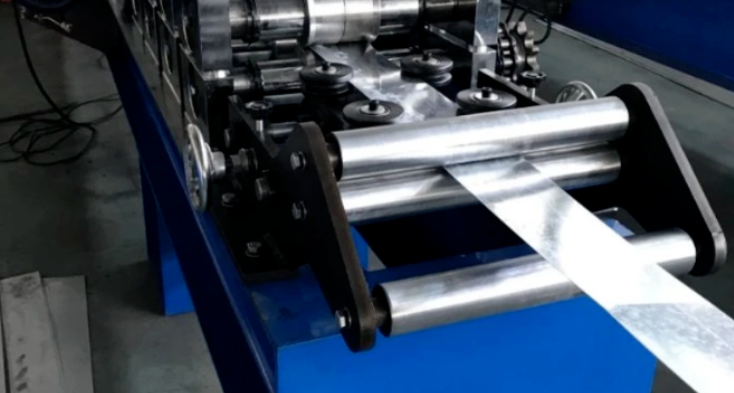

When it comes to outdoor structures like pergolas and patios, durability and weather resistance are paramount. The materials used must be able to withstand the elements while maintaining their structural integrity and aesthetic appeal. Roll forming technology has emerged as a game-changer in producing metal components specifically designed for outdoor applications. This blog will explore how roll-formed metal components excel in durability and weather resistance and the benefits of coatings and finishes that enhance their longevity.

Resistance to Rust

One of the standout features of roll-formed metals, particularly galvanized steel and aluminum, is their resistance to rust. Traditional materials, such as wood or untreated metals, are susceptible to moisture, leading to decay and corrosion over time. In contrast, roll-formed metals undergo treatment processes that protect against rust formation, making them ideal for outdoor use. The protective coatings applied during production prevent moisture from penetrating the surface, ensuring that your structures remain robust and reliable for years to come.

Weather Resistance

Roll-formed metal components are engineered to endure a range of harsh weather conditions. Whether it's relentless rain, snow, or intense UV exposure, these metals are designed to resist the damaging effects of the elements. Unlike wood, which can warp and weaken over time, roll-formed metals maintain their structural integrity, offering peace of mind for homeowners and contractors alike. With roll forming, you can invest in outdoor structures that withstand the test of time, regardless of the weather conditions.

Long-Term Wear

The structural integrity of roll-formed metals is another reason they are favored for outdoor applications. These components are designed to endure mechanical stresses and physical wear without compromising strength. The lightweight yet sturdy nature of roll-formed metals makes them ideal for supporting structures like pergolas and patios, ensuring that they remain stable and functional over long periods.

Coating Options

To further enhance the durability of roll-formed metal components, various coatings can be applied during the roll forming process. Powder coating is one popular option, providing a tough, protective layer that shields the metal from corrosion and UV damage. Anodizing, commonly used for aluminum, adds an extra layer of protection while also improving aesthetic appeal. These coatings not only enhance the longevity of the materials but also minimize maintenance needs, making them a practical choice for outdoor structures.

Finishing Techniques

In addition to protective coatings, various finishing techniques can improve both the appearance and functionality of roll-formed metal components. Finishing processes ensure that the surfaces are smooth and free from imperfections, enhancing their aesthetic appeal. Moreover, finishes can be tailored to meet specific project requirements, allowing for greater customization. Whether you prefer a sleek, modern look or a more traditional finish, roll forming offers the flexibility to achieve your desired design while ensuring durability.

Structural Components

Roll-formed metal components are integral to the construction of pergolas and patios. Elements such as beams, rafters, and brackets are commonly produced using roll forming technology. These components contribute significantly to the overall durability and stability of the structures. By utilizing roll-formed metals, contractors can create robust designs that not only look great but also stand strong against the elements.

Design Flexibility

Another advantage of roll forming is its versatility in design. The technology allows for custom profiles and shapes, enabling manufacturers to produce components that meet specific aesthetic and functional requirements. This flexibility ensures that each pergola and patio can be tailored to fit the unique needs of the project while maintaining the highest standards of durability and weather resistance.

In conclusion, roll forming technology offers numerous benefits for producing durable and weather-resistant metal components for outdoor structures. The resistance to rust, ability to withstand harsh weather conditions, and long-term wear make roll-formed metals an ideal choice for pergolas and patios. Additionally, the option to apply protective coatings and finishes enhances their lifespan and aesthetic appeal.

By choosing roll-formed metal components for your outdoor projects, you can ensure that your structures are not only beautiful but also built to last. Whether you’re a homeowner looking to enhance your outdoor space or a contractor seeking reliable materials for your projects, roll forming provides a robust solution that stands the test of time.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.