With Qatar’s expanding industrial sector, roll forming machines have become essential for construction, manufacturing, and other industries. However, buying the right machine—whether new or used—requires a careful approach to ensure it meets both local standards and specific business needs.

1. New Roll Forming Machines for Sale in Qatar

New roll forming machines offer a variety of benefits, from cutting-edge technology to warranties and minimal maintenance concerns. However, to get the most out of your investment, it’s essential to choose a machine that’s compatible with Qatar's industrial requirements.

- Advantages of New Machines: New roll forming machines come with factory warranties, cutting-edge features, and are generally more reliable for high-volume production. With fewer maintenance issues, new machines offer peace of mind and faster return on investment.

- Choosing the Right Profile: Profiles are the shapes or patterns produced by roll forming machines. In Qatar’s construction-heavy market, popular profiles include roofing panels, wall panels, C and Z purlins, and structural profiles. Ensure that the machine you choose can produce profiles that match industry demands or project specifications in Qatar.

- Power Supply Considerations:

- Qatar’s power grid primarily operates at a voltage of 240V (single-phase) or 415V (three-phase). Ensuring your machine matches these standards is critical to avoid costly modifications.

- Before purchasing, verify the power requirements of the machine and ensure they align with the local supply. Some machines might require transformers or other adjustments to function optimally in Qatar.

- Material Compatibility:

- Different roll forming machines are designed to work with various materials like galvanized steel, aluminum, and even stainless steel. Knowing the type and thickness of the material commonly used in Qatar’s projects is crucial for selecting the right machine.

- Choose a machine that can handle the gauge (thickness) of materials you’ll be working with, as thicker or denser materials require more powerful machinery.

- Maintenance and Support:

- In Qatar, the availability of local service centers or trained technicians is essential for keeping your machine in peak condition. Many reputable manufacturers offer maintenance plans and local support, making maintenance manageable.

- Additionally, review the warranty options provided by manufacturers to see if extended warranties or service contracts are available.

2. Used Roll Forming Machines for Sale in Qatar

For companies aiming to reduce upfront costs, buying a used roll forming machine can be a cost-effective option. However, a used machine may come with limitations and require more due diligence to ensure it meets your operational needs.

- Advantages of Buying Used Machines: Used machines are typically more affordable and are available faster than new models. For businesses starting with limited budgets or lower production needs, a used machine can be an excellent choice.

- Assessing Machine Condition:

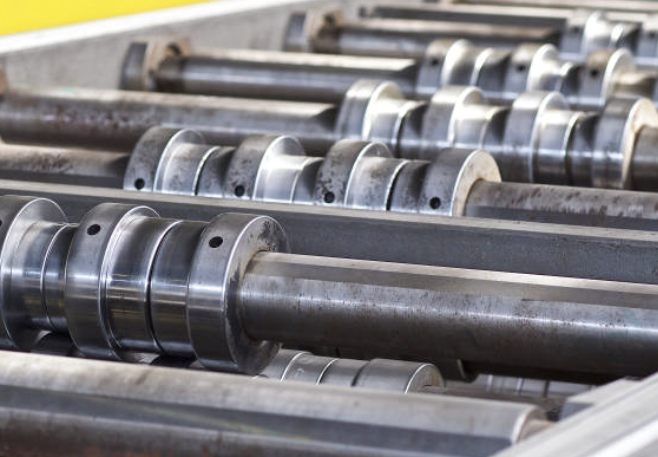

- Inspect the machine for wear and tear, especially in critical areas like rollers, which endure the most stress. Check the electronics and the overall structure to confirm they’re in good working order.

- Many sellers allow a testing period. It’s wise to run a few sample pieces through the machine to identify any operational issues.

- Power Supply Compatibility for Used Machines:

- Used machines imported from other countries may have different power requirements. For example, machines from North America may operate on 220V or 110V, while those from Europe may be similar to Qatar’s 240V.

- Ensuring compatibility with Qatar’s power standards is crucial, and adjustments may involve additional costs. Work with a trusted technician to assess and modify power settings as needed.

- Profile Limitations:

- Unlike new machines, used machines often have limited profile flexibility. They may only support specific profiles, which can limit your product range if you need to meet diverse client demands.

- Check that the used machine supports the profiles most requested in Qatar’s market to avoid costly upgrades or custom modifications.

- Documentation and History:

- To protect your investment, ensure the machine comes with detailed documentation, including maintenance records and any previous repairs. This history can provide insights into potential future issues and help you negotiate pricing.

- When possible, consider having a third-party inspection performed to validate the machine’s condition and identify any hidden issues.

3. Comparing New vs. Used Machines for Different Use Cases in Qatar

When deciding between a new and a used roll forming machine, consider these factors based on Qatar’s unique industrial needs:

- Budget Considerations: New machines have a higher upfront cost but may offer better long-term value with lower maintenance. If you have a limited budget, used machines are a viable option, though you should account for possible upgrades or repairs.

- Production Volume Needs: High-volume production is typically better suited to new machines, which are optimized for efficiency and reliability. Used machines may suffice for lower-volume needs or businesses in the early growth phase.

- Energy Efficiency:

- Qatar’s hot climate makes energy efficiency an essential factor in keeping costs low. Newer machines are often designed with energy efficiency in mind, helping to reduce power costs, which is a critical advantage in Qatar’s energy-intensive industrial settings.

- Flexibility in Profile Adjustments:

- A key advantage of new machines is their adaptability; many modern roll forming machines allow for profile adjustments to meet changing client demands. This is especially valuable in Qatar, where construction needs can vary widely.

- For used machines, ensure any necessary profile adjustments are feasible without excessive modification costs.

Conclusion

Investing in a roll forming machine in Qatar requires a thorough assessment of your business needs, budget, and local conditions. Whether you’re considering a new or used machine, take the time to evaluate factors like power supply compatibility, profile requirements, and material handling capabilities. For businesses in Qatar, a carefully chosen roll forming machine can support efficient production and help achieve a competitive edge in the thriving industrial landscape.

Choosing wisely will not only optimize productivity but also help avoid costly modifications, ensuring your machine serves as a valuable asset for years to come.