As the manufacturing landscape in Vietnam continues to expand, roll forming machines have become essential assets for businesses involved in metalworking, roofing, and construction materials production. However, purchasing a roll forming machine can be a complex decision, especially with the differences between new and used options.

New Roll Forming Machines for Sale in Vietnam

Investing in a new roll forming machine offers several benefits, from the latest technology to minimal wear. However, to make the most of this investment, consider the following factors:

1.1 Profile Selection

- Profile Variety: One of the most crucial aspects when buying a roll forming machine is ensuring it supports a wide range of profiles. In Vietnam, popular profiles include roofing sheets, wall panels, and even custom profiles for specific industrial applications. Choosing a machine that allows for flexibility and customization in profile production can add significant value, especially for businesses targeting both local and export markets.

- Market Trends: The demand for specific profiles may change over time. If you’re in a competitive market or export-oriented, consider machines that allow you to quickly adjust or add new profiles, ensuring your investment stays relevant to market demands.

1.2 Power Supply Compatibility

- Local Power Standards: Vietnam’s power grid operates at 220 volts and 50 hertz. If you are importing a roll forming machine, especially from countries like the United States (110V, 60Hz) or Japan (100V, 50Hz), make sure the machine’s power requirements align with Vietnam’s standards. Machines compatible with local power standards often operate more efficiently and require less adaptation.

- Adaptability for Export: If your business plans to sell profiles in international markets or plans to export the machine later, choose one that can handle dual voltage or frequency standards. Many new machines now offer flexibility in power compatibility, allowing them to operate smoothly in multiple countries.

1.3 Technological Advancements

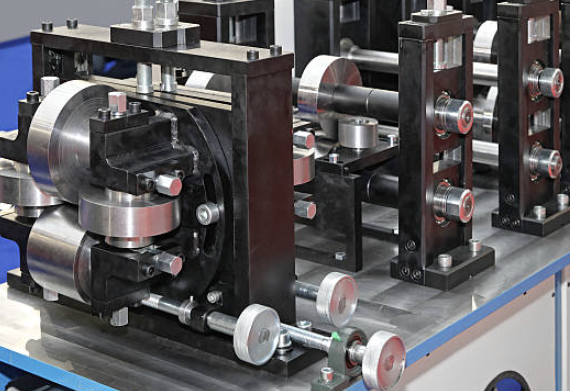

- New roll forming machines come equipped with advanced features that make operations smoother and more efficient. Automation, digital controls, and precision tooling options are standard in many modern machines. These features not only improve productivity but also help maintain consistent product quality, which is a huge advantage when trying to meet the demands of high-volume production.

1.4 Warranty and After-Sales Support

- Purchasing a new machine often comes with a warranty, which can be invaluable. Warranties cover manufacturing defects, and some may include routine maintenance, significantly lowering your operational costs. Additionally, after-sales support from manufacturers or authorized agents is crucial for troubleshooting, maintenance, and accessing spare parts. This level of support is often much better with new machines and should be a top consideration for long-term success.

Used Roll Forming Machines for Sale in Vietnam

Buying a used roll forming machine can be a budget-friendly option, especially for businesses looking to keep their initial investment low. However, used machines require careful consideration to ensure they will meet your needs:

2.1 Condition of Machine and Profile Availability

- Inspect Profile Compatibility: When looking at used machines, verify the profiles it can produce. Some machines may be limited to specific profiles, and modifying them for new profiles can be challenging and costly. Make sure the machine can handle the profiles your business requires or check if it’s possible to add new tooling for additional profiles.

- Profile Wear and Maintenance: The tooling on used machines may show signs of wear, which can lead to inconsistent profiles and increased maintenance costs. It’s essential to thoroughly inspect the machine’s condition, especially the dies and rollers, to ensure they can produce the desired profiles without issues.

2.2 Power Supply Modifications

- Assessing Power Supply Requirements: Power compatibility is especially important with used machines, which may have older or non-standard power configurations if imported from other countries. If the machine is from a country with a different voltage or frequency (e.g., 110V or 60Hz), converting it to work on Vietnam’s 220V, 50Hz power grid may require additional equipment.

- Conversion Equipment: If the used machine isn’t compatible with Vietnam’s power supply, you may need a transformer or power converter, which adds cost and can sometimes affect machine performance. Be sure to factor in these potential expenses when comparing used machines to new ones.

2.3 Cost Savings vs. Long-Term Maintenance

- Initial Savings: One of the main reasons buyers opt for used machines is the lower initial cost. However, be aware that older machines may need more frequent maintenance and repairs, especially if they’ve been heavily used. While these machines can be a great bargain upfront, it’s essential to weigh the initial savings against the potential long-term maintenance costs.

- Access to Spare Parts: Another factor with used machines is the availability of spare parts. Some older models may no longer have manufacturer support, which can make finding parts difficult. If parts are not readily available, the machine may end up costing more in repairs or downtime. It’s a good idea to choose a model with readily available parts, or a brand with a strong aftermarket network in Vietnam.

Conclusion

Choosing the right roll forming machine for your business in Vietnam involves more than just comparing prices. Factors like profile versatility, power supply compatibility, machine condition, and after-sales support can significantly impact your operation’s productivity and profitability. By carefully considering these aspects, you can ensure that your investment in either a new or used roll forming machine will meet your business needs now and in the future.