Posted on Tuesday, October 8, 2024

As the roofing industry evolves, the demand for high-quality, durable materials continues to rise. Among these materials, metal drip edges have become essential in ensuring effective water drainage and protecting the structural integrity of roofs. To meet this increasing demand, manufacturers must leverage advanced production techniques, and roll forming technology stands out as a game-changer. In this blog, we’ll explore how roll forming machines enable metal drip edge manufacturers to scale their production effectively while maintaining quality and efficiency.

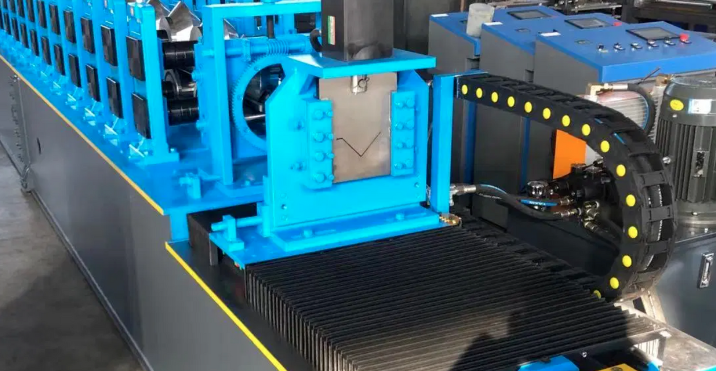

What is Roll Forming?

Roll forming is a continuous bending process that transforms flat metal strips into desired cross-sectional shapes using a series of rollers. This technology is known for its efficiency and precision, making it ideal for producing metal components like drip edges.

Precision and Consistency

One of the primary advantages of roll forming is its ability to produce uniform profiles consistently. The precision of roll forming machines ensures that each drip edge meets stringent industry standards, offering manufacturers a reliable solution for high-quality production. This consistency is crucial for maintaining the integrity and performance of roofing systems.

Increased Efficiency

Roll forming technology significantly enhances production efficiency. Unlike traditional manufacturing methods, which may require multiple setup changes and manual labor, roll forming allows for rapid production rates. Manufacturers can produce thousands of feet of metal drip edges in a fraction of the time, enabling them to meet growing market demands swiftly.

Flexible Configurations

Modern roll forming machines are designed with flexibility in mind. They can be easily adjusted to produce various drip edge profiles, accommodating changes in design and customer preferences. This adaptability ensures that manufacturers can respond quickly to market trends and customer needs without significant downtime or retooling costs.

Automation and Labor Savings

Automation is a key feature of advanced roll forming systems. By minimizing the need for manual intervention, manufacturers can reduce labor costs and human error, leading to greater overall efficiency. Automated systems not only speed up production but also enhance the safety of the manufacturing process, allowing skilled workers to focus on higher-value tasks.

Responding to Trends

The roofing industry is witnessing a shift towards eco-friendly materials and innovative designs. Roll forming technology allows manufacturers to adapt quickly to these emerging trends. For example, producers can experiment with different metal alloys or coatings, ensuring their products meet sustainability criteria while maintaining performance.

Production Capacity

As demand for metal drip edges continues to grow, the scalability of roll forming machines becomes crucial. Manufacturers can ramp up production volumes to meet increasing market demands without sacrificing quality. This ability to scale efficiently helps manufacturers stay competitive in a rapidly changing industry landscape.

Several manufacturers have successfully integrated roll forming technology to expand their production capabilities. For instance, a leading metal roofing company implemented a state-of-the-art roll forming line, increasing their production capacity by over 50% within six months. This investment not only allowed them to meet rising customer demand but also improved their operational efficiency, significantly reducing lead times for projects.

In today’s competitive roofing industry, metal drip edge manufacturers must embrace innovative production technologies to thrive. Roll forming machines offer a powerful solution, enabling manufacturers to scale their production while ensuring quality and efficiency. By investing in roll forming technology, manufacturers can adapt to changing market demands, stay ahead of industry trends, and ultimately enhance their bottom line.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.