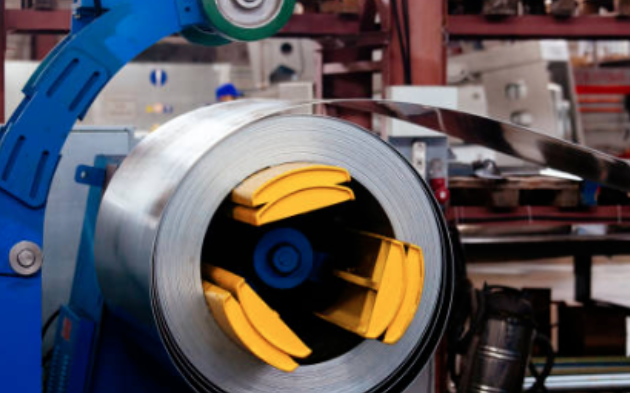

Proper coil alignment is crucial for the efficient operation of roll forming machines. When coils are misaligned, it can lead to a range of issues that affect both production quality and machine longevity. This blog post will highlight the importance of coil alignment and provide practical tips to maintain it, ensuring optimal performance in your roll forming operations.

Why Coil Alignment Matters

- Smooth Operation: Proper alignment ensures that the coil feeds smoothly into the roll forming machine. Misalignment can cause the coil to snag or bind, leading to increased wear on machine components and potential breakdowns.

- Quality of Finished Products: Misaligned coils can lead to inconsistencies in the formed metal profiles, resulting in defects such as uneven edges, irregular shapes, and compromised structural integrity. Ensuring proper alignment helps maintain the quality standards expected in the industry.

- Reduced Downtime: Coil slippage or deformation can halt production, leading to costly downtime. Maintaining alignment minimizes these risks, allowing for continuous and efficient operation.

- Cost Efficiency: Ensuring proper coil alignment reduces waste generated from defective products and minimizes the need for repairs or replacements of damaged equipment. This contributes to overall cost savings in the production process.

Practical Tips for Maintaining Coil Alignment

- Regular Inspection: Implement a routine inspection schedule to check the alignment of coils before and during production. Look for signs of misalignment, such as uneven coil edges or signs of wear on the feeding mechanism.

- Use of Alignment Tools: Invest in specialized tools and equipment designed to assist with coil alignment. These tools can help adjust and maintain the correct position of the coil as it feeds into the roll forming machine.

- Proper Coil Handling: Ensure that operators are trained in the correct handling of coils during loading and setup. Improper handling can lead to coil deformation or slippage, affecting alignment.

- Adjust Roll Forming Equipment: Regularly calibrate and adjust the roll forming machine’s components, such as rollers and guides, to ensure they are functioning correctly and maintaining coil alignment throughout the forming process.

- Monitor Coil Tension: Proper tension on the coil is essential for maintaining alignment. Too much tension can cause deformation, while too little can lead to slippage. Monitor and adjust the coil tension as needed to keep it within optimal levels.

- Address Environmental Factors: Keep the production area free from dust, debris, and moisture that can affect coil performance. Environmental factors can lead to coil expansion or contraction, which may impact alignment.

- Feedback Mechanisms: Implement a feedback system where operators can report alignment issues immediately. This will help identify patterns or recurring problems, allowing for timely interventions and adjustments.

By emphasizing the importance of coil alignment and implementing these practical tips, roll forming manufacturers can enhance their operational efficiency, improve product quality, and ultimately reduce costs. Properly aligned coils are the backbone of a smooth and productive roll forming process, making it essential to prioritize this aspect of machine operation.