Posted on Saturday, October 19, 2024

Roll forming machines are a critical investment for manufacturers in Croatia, particularly those involved in industries such as construction, automotive, and renewable energy. However, the cost of acquiring one can vary significantly depending on several factors. This guide breaks down the key elements that influence the price of a roll forming machine and offers advice on how Croatian buyers can budget for their purchase.

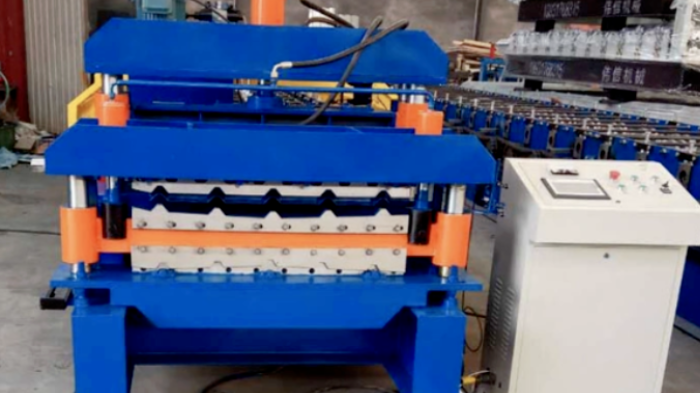

One of the most significant factors influencing the cost of a roll forming machine is its size and complexity. Machines that produce simple profiles such as gutters or roofing panels are generally less expensive than those designed for complex or customized profiles. If your business requires a machine capable of handling multiple profiles or intricate designs, expect the cost to increase.

Tip: Before making a purchase, evaluate the specific profiles your business needs. Opting for a machine with just the right capabilities can help control costs.

The type of material your roll forming machine will work with also impacts its cost. Machines designed to handle thicker materials, such as steel, or more specialized metals like aluminum, are typically more expensive due to the additional strength and precision required. The width and gauge of the metal coils you plan to use also factor into the price, as machines need to be calibrated to handle specific material properties.

Tip: Determine the types of materials and thicknesses your machine will need to process before selecting a model. Tailoring the machine to your exact requirements will help you avoid unnecessary costs.

Modern roll forming machines come equipped with varying levels of automation, from manual systems to fully automated solutions with advanced software controls. Machines that offer automated setups, real-time monitoring, and quality control systems are more expensive but can significantly reduce labor costs and production time, ultimately offering better long-term value.

Tip: Assess whether the additional cost of automation can be justified by the savings in labor and increased production speed. For larger-scale operations, automation may lead to a higher return on investment.

Some industries in Croatia may require roll forming machines with unique capabilities, such as producing specific profiles or accommodating specialized production processes. Customizing a machine to meet these needs typically adds to the overall cost. However, a tailored machine ensures that your production line runs smoothly, especially if you require non-standard profiles.

Tip: Work closely with manufacturers to determine if a standard machine can be adjusted to your needs or if a fully customized machine is necessary.

For Croatian buyers, the cost of shipping and importing the machine from international manufacturers can be a significant expense. Depending on the country of origin, factors like customs duties, taxes, and logistics costs will affect the total price.

Tip: When budgeting for a roll forming machine, be sure to include the cost of shipping and import duties. Working with European suppliers may help reduce these costs.

Roll forming machines are long-term investments, and regular maintenance is essential to keep them running efficiently. Opting for a machine that comes with reliable local technical support can prevent costly downtime. Machines with longer warranties or easy access to spare parts may come at a premium, but these features help ensure continuous operation.

Tip: Choose a supplier that offers local service and maintenance options in Croatia. This will save you time and money in the event of a breakdown or routine maintenance needs.

With rising energy costs in Croatia, energy-efficient machines can help save money in the long run. While energy-efficient models may have a higher initial cost, they can reduce ongoing operational expenses, especially in industries with high production volumes.

Tip: Factor in the machine’s energy consumption and consider the long-term savings on electricity when deciding between different models.

When budgeting for a roll forming machine in Croatia, it’s important to account for not only the purchase price but also the additional expenses that come with installation, operation, and maintenance. Here are a few steps to help you budget effectively:

Investing in a roll forming machine in Croatia requires careful consideration of various factors that affect both the upfront and ongoing costs. By understanding these elements and planning your budget accordingly, you can ensure that your investment delivers long-term value and supports the growth of your business.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.