Posted on Tuesday, October 1, 2024

A runout gauge in roll forming is a precision tool used to measure the straightness and accuracy of the profile's final dimensions after it exits the roll forming machine. It plays a critical role in maintaining product quality by detecting any deviations or imperfections in the length, width, or alignment of the rolled metal.

By monitoring the dimensional consistency of roll-formed products, the runout gauge helps manufacturers produce high-quality components for industries where precision is critical, such as construction, automotive, or aerospace.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

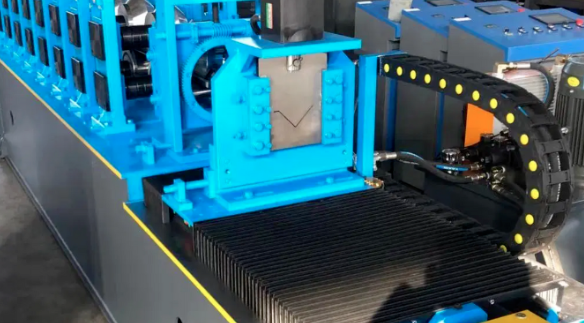

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.