Posted on Saturday, November 16, 2024

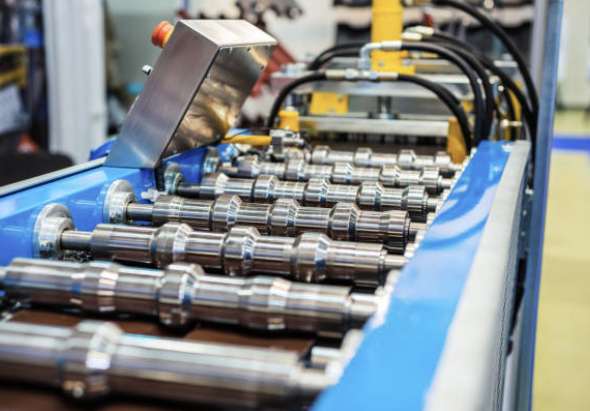

Automation in the roll-forming industry is revolutionizing how businesses operate, offering unmatched benefits in efficiency, precision, and scalability. This blog not only explores the advantages and implementation strategies for automation but also features a practical case study to illustrate its transformative potential.

Roll-forming businesses face constant pressure to deliver high-quality products at competitive prices. Automation directly addresses these challenges by:

Company: MetalForm Solutions Inc.

Industry: Roofing and Cladding Profiles

Location: United Arab Emirates

Challenge:

MetalForm Solutions struggled with meeting high-volume orders for custom roofing profiles due to manual processes, which led to frequent errors, delays, and increased labor costs.

Solution:

They invested in an automated standing seam roll-forming machine featuring:

Outcome:

ROI: Achieved within 18 months due to increased order capacity and reduced labor costs.

Evaluate areas like:

Select machines that align with your production needs. For example:

Invest in machines with IoT and real-time monitoring capabilities to optimize production.

Upskill your workforce to operate, maintain, and troubleshoot automated systems.

Ensure new machines can communicate with existing infrastructure for seamless operations.

Automation allows roll-forming machines to operate at speeds of up to 40m/min, depending on the profile and material.

Automated adjustments ensure consistent profile dimensions and material gauge.

Easily switch between profiles with minimal downtime using pre-programmed settings.

Automating your roll-forming business is not just a technological upgrade—it’s a strategic investment in the future. Companies like MetalForm Solutions have demonstrated how automation can enhance efficiency, reduce costs, and improve customer satisfaction.

By carefully planning and implementing automation, your business can stay ahead in an increasingly competitive market. From reducing errors to achieving faster production times, automation is a game-changer for roll-forming manufacturers.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.