Posted on Monday, November 4, 2024

Investing in roll forming machines can significantly enhance the production capabilities of small businesses in Jordan, enabling efficient manufacturing of metal profiles for various applications. To make this investment cost-effective, consider the following strategies:

1. Assess Your Production Needs

2. Explore Budget-Friendly Machine Options

3. Evaluate Financing Options

4. Consider Total Cost of Ownership

5. Plan for Future Expansion

By carefully assessing your needs, exploring various machine options, and considering flexible financing solutions, your small business in Jordan can effectively invest in roll forming machines to enhance production capabilities and support growth.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

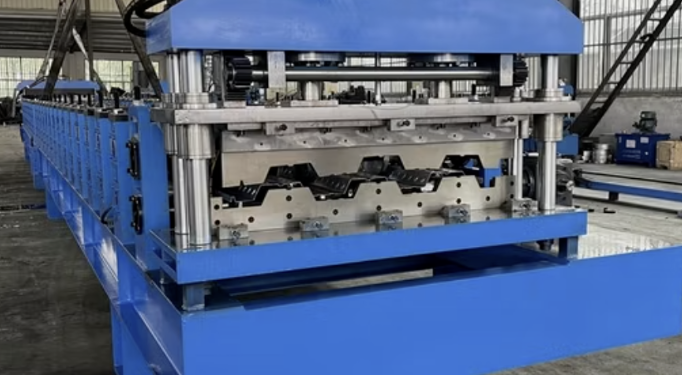

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.