Posted on Thursday, November 14, 2024

In today’s competitive global market, quality and compliance are more than just regulatory requirements—they are a commitment to excellence and customer satisfaction. For Israeli industries relying on roll forming machines, ensuring compliance with both Israeli and international quality standards is essential to remain competitive and meet customer expectations. This guide provides an overview of key compliance and quality assurance considerations for roll forming machine usage in Israeli industries.

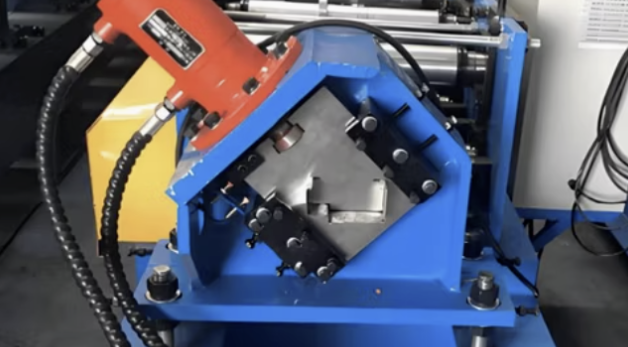

Roll forming machines are integral to various Israeli industries, including construction, automotive, agricultural, and manufacturing sectors. Ensuring these machines meet regulatory standards is crucial for delivering products that are both reliable and safe. Compliance with quality standards assures customers that products will meet specific performance criteria, withstand environmental conditions, and be safe for use. Moreover, adherence to standards boosts credibility and enhances the company’s market reputation.

Israeli industries must often comply with a combination of local and international standards. Here are some essential standards to consider:

These standards help align production practices with globally accepted quality levels, ensuring compatibility with the broader market and enhancing product reliability.

Sourcing compliant roll forming machines is critical to maintaining quality standards in production. Here are some steps to ensure machine compliance:

Establishing rigorous quality control practices is fundamental for consistent, high-quality outputs. Here are some common practices:

Trained operators are critical to achieving and maintaining compliance. Training ensures that operators understand how to use the machines effectively, monitor quality, and adhere to regulatory guidelines.

Environmental and safety compliance are vital components of responsible production. Israeli industries are increasingly expected to consider environmental impacts, particularly in waste management and energy efficiency.

Even with strict adherence to guidelines, challenges can arise in ensuring compliance. Here are a few common issues and ways to address them:

Compliance with quality and regulatory standards is a long-term investment that pays off through improved product reliability, higher customer satisfaction, and increased market credibility. By adopting rigorous quality control practices, training operators, and selecting machines that meet Israeli and international standards, companies can achieve consistent excellence in roll forming production. For Israeli industries, compliance is not only a requirement but also a powerful strategy for growth and competitiveness in the global market.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.