Posted on Tuesday, November 19, 2024

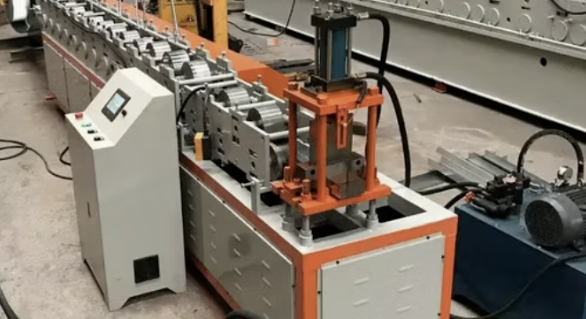

Panama's strategic location and thriving economy provide a ripe market for industries that rely on roll forming machines, particularly in construction, infrastructure, and manufacturing. To capitalize on this growing demand, businesses need to optimize their roll forming production processes for maximum efficiency and quality. Here are key strategies to help manufacturers meet local and regional demands effectively.

Panama’s booming construction sector, driven by infrastructure projects and real estate developments, is fueling demand for specific roll-formed products such as roofing sheets, structural profiles, and cladding. Manufacturers should:

Efficiency is critical in meeting increasing demand without compromising quality. Investing in modern, high-speed roll forming machines can:

Panama's unique geographical and climatic conditions call for products with specific features. Roll forming machines tailored to these needs can:

Automation and digital technologies are game-changers for production optimization:

Panama’s position as a logistical hub offers significant opportunities but also challenges:

Sustainability is increasingly important in Panama’s market, with many projects aiming for eco-friendly certification:

Flexibility to meet diverse customer needs is a competitive advantage:

Maximize the potential of your machinery with a skilled team:

Collaborate with local distributors, engineers, and architects to better understand regional demands and strengthen your market presence.

By aligning your roll forming production processes with Panama's growing economic and industrial demands, you can enhance efficiency, increase profitability, and establish a strong foothold in this vibrant market. Leveraging advanced technology, local insights, and sustainable practices will position your business as a key player in Panama's roll forming industry.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.