Posted on Saturday, November 2, 2024

In Colombia's fast-growing construction and industrial sectors, the importance of choosing the right metal profiles cannot be overstated. Metal profiles form the backbone of many structures, providing strength, stability, and efficiency across various applications. In this blog, we’ll explore how roll forming innovations are optimizing metal profiles in Colombia, contributing to greater structural integrity, cost savings, and project efficiency.

Colombia’s diverse construction and industrial projects demand a variety of metal profiles, each serving specific structural and functional needs. Here are some of the most commonly used metal profiles in Colombian manufacturing:

Each of these profiles is engineered to optimize performance in various environmental conditions across Colombia, from humid coastal areas to high-altitude regions with significant temperature fluctuations.

The primary role of metal profiles in construction and industrial applications is to provide structural integrity. The shape and thickness of each profile contribute to its load-bearing capabilities, distributing weight effectively to prevent deformation and improve stability. Let’s break down how these profiles enhance structural performance:

By choosing the right profiles for each application, Colombian manufacturers can ensure safety and durability in projects across different sectors.

One of the biggest advantages of optimizing metal profiles is the cost savings achieved in material usage and manufacturing. Roll forming innovations enable manufacturers to create profiles with minimal waste, which can have a significant impact on overall project costs. Here’s how:

As a result, optimized metal profiles not only enhance project efficiency but also contribute to environmental sustainability through reduced material waste.

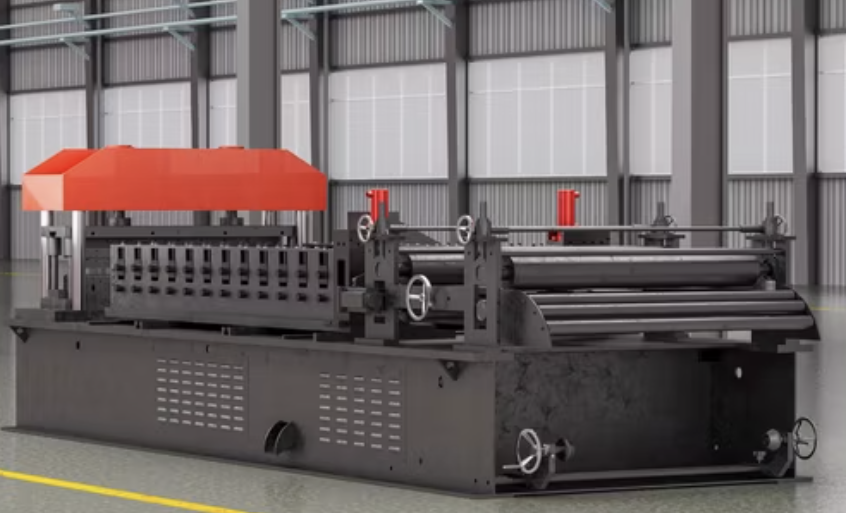

Recent advancements in roll forming technology have opened up new possibilities for manufacturing metal profiles in Colombia. Here are a few innovations that are transforming the industry:

With these advancements, manufacturers can produce high-quality profiles faster, enhancing both productivity and customer satisfaction.

Efficiency in production is essential for maintaining timelines in Colombia’s fast-paced construction sector. Modern roll forming technology has made it possible to produce profiles in large quantities without sacrificing quality. Here’s how roll forming contributes to faster project completion:

By reducing lead times and ensuring a steady supply of profiles, roll forming technology helps Colombian manufacturers keep projects on track, even with tight deadlines.

As Colombia continues to develop its infrastructure and industrial base, the demand for metal profiles will only grow. Here are some trends likely to shape the future of metal profile manufacturing in Colombia:

By staying at the forefront of these trends, Colombian manufacturers can continue to meet the demands of an evolving market while enhancing their competitive edge.

Optimizing metal profiles through roll forming innovations is transforming Colombia’s construction and industrial sectors. By leveraging advanced manufacturing techniques, manufacturers can produce high-quality profiles that enhance structural integrity, reduce material costs, and streamline project timelines. As Colombia’s demand for efficient, durable, and sustainable materials grows, roll forming technology will continue to play a pivotal role in shaping the future of Colombian manufacturing.

With the right metal profiles in place, Colombian companies are better equipped to build stronger, safer, and more efficient structures, contributing to the country’s ongoing growth and development.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.