Posted on Monday, November 4, 2024

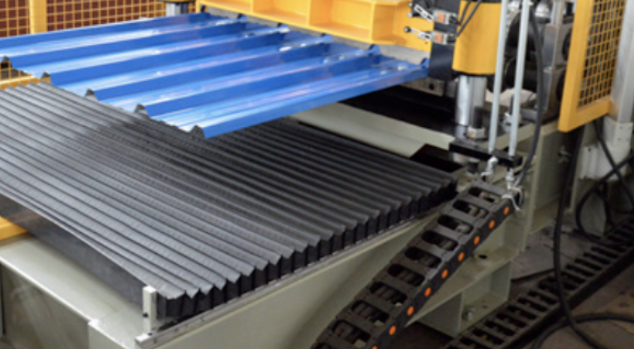

Roll forming machines have become essential for Denmark’s manufacturing and construction industries. These machines, which shape long strips of metal into specific profiles, are widely used in creating roofing, wall panels, steel doors, and structural components. Whether you’re looking to purchase a new or used roll forming machine, there are several important factors to consider. From understanding Denmark’s power supply standards to selecting the right profiles, this guide will walk you through the crucial aspects to ensure a successful purchase.

Buying a new roll forming machine offers several advantages, including the latest technology, customization options, and comprehensive support. However, there are some considerations to keep in mind:

Key Considerations for New Machines

For businesses looking to reduce upfront costs, buying a used roll forming machine can be an excellent alternative. However, evaluating the machine’s condition and compatibility is critical for a wise investment.

Key Considerations for Used Machines

Beyond choosing between new and used machines, other practical considerations will impact the purchasing process.

Q1: What profile types are most suitable for the Danish market?

A: Commonly used profiles in Denmark include roofing panels, wall cladding, and guttering systems. For industrial applications, heavy-duty structural profiles are also popular. Consult with your supplier to ensure the machine can produce the profiles relevant to your market needs.

Q2: Can I buy a roll forming machine from another country and use it in Denmark?

A: Yes, but compatibility with Denmark’s power supply (230V or 400V) is crucial. If the machine’s specifications differ, you may need a transformer or other adjustments. Be sure to confirm power compatibility with the supplier before purchasing.

Q3: How can I determine the quality of a used roll forming machine?

A: Start by inspecting key components like the rollers, motor, and control systems. Request a maintenance history and, if possible, test the machine in operation. Consulting a local technician or supplier for a detailed inspection is also recommended.

Q4: Are there financing options available for buying new or used roll forming machines?

A: Many suppliers offer financing plans, and some Danish banks provide loans specifically for equipment purchases. Look into financing options that offer favorable terms, especially if you’re purchasing a new machine.

Q5: What additional features should I consider for a new machine?

A: Features like automated stackers, remote PLC systems, and safety enclosures can increase efficiency and safety. In high-volume operations, these additions may justify their cost by boosting productivity and reducing operator intervention.

Q6: Do I need special permits or certifications to operate a roll forming machine in Denmark?

A: Generally, operating a roll forming machine doesn’t require special permits, but your machine must comply with Danish and EU safety and environmental standards. Check with local authorities if you’re unsure about specific certifications.

Purchasing a roll forming machine in Denmark requires careful consideration of profile needs, power compatibility, cost factors, and compliance with local regulations. Whether you’re buying new or used, taking the time to evaluate your options will help ensure that your investment supports your business goals effectively. Remember to work closely with your supplier to address any specific needs and to maximize the machine’s lifespan and productivity in your operation.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.