Posted on Friday, November 15, 2024

Turkey's thriving manufacturing sector makes it an ideal market for roll forming machines. Whether you are buying new or used, understanding your specific needs and the local considerations is essential. This guide breaks down the factors to consider when purchasing roll forming machines in Turkey.

Investing in a new roll forming machine can provide the latest technology, enhanced precision, and lower maintenance costs.

Used machines can be a cost-effective option for businesses with budget constraints.

Q1: Is it better to buy a new or used roll forming machine in Turkey?

A1: It depends on your budget and production needs. New machines offer the latest technology and lower maintenance costs, while used machines can be cost-effective but require thorough inspection and possible modifications.

Q2: How do I ensure the machine is compatible with Turkey's power supply?

A2: Verify the machine's power requirements (voltage and frequency) and ensure they match Turkey's standards (230V/50Hz single-phase or 400V/50Hz three-phase).

Q3: What profiles are most in demand in Turkey?

A3: Common profiles include roofing panels, highway guardrails, and agricultural structures. Your choice should align with the market demand in your industry.

Q4: Can I modify a used roll forming machine to create different profiles?

A4: Yes, but it might require new rollers and adjustments to the hydraulic and PLC systems. Factor in the cost and time for these modifications.

Q5: What after-sales services should I expect from a supplier?

A5: Look for local support, availability of spare parts, operator training, and a warranty for new machines.

This guide aims to equip you with the knowledge to make an informed decision. Whether you choose a new or used roll forming machine, understanding Turkey's unique requirements will ensure a successful investment.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

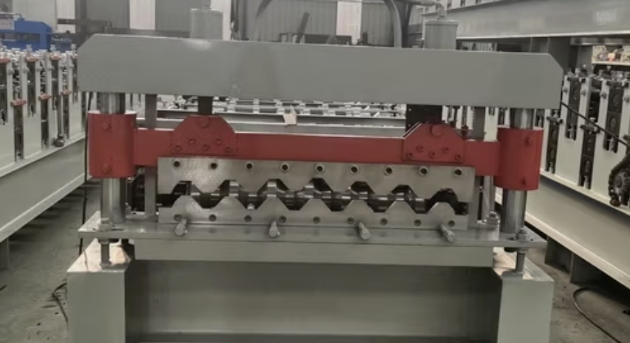

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.