Posted on Wednesday, November 13, 2024

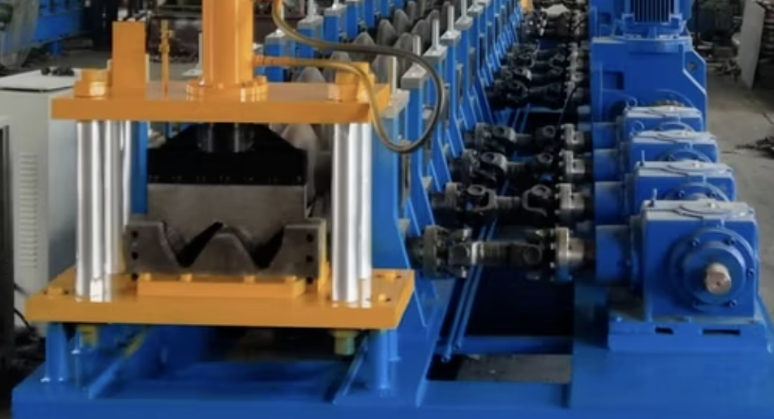

Roll forming machines are essential in Zimbabwe’s manufacturing and construction industries. They provide an efficient, high-speed method to produce metal profiles used in building materials, agricultural tools, and infrastructure. However, purchasing a roll forming machine in Zimbabwe requires careful consideration of local market demands, power supply standards, and available infrastructure. This guide will walk you through the most critical factors to consider, whether you’re looking for a new or used machine, and provide answers to common questions to help you make an informed decision.

When purchasing a new roll forming machine in Zimbabwe, focus on factors that can influence its performance, longevity, and suitability for your specific needs.

Opting for a new roll forming machine offers several benefits:

If your budget is limited, a used roll forming machine can be a practical alternative. However, it’s essential to examine the machine’s condition and determine if it can meet your business needs.

In addition to choosing between new and used, consider these factors to make the most suitable choice for your business:

Q1: What profile should I choose for my roll forming machine?

A: This depends on your industry and customer demand. For construction, roofing profiles are popular, while agricultural and structural profiles are commonly used in industrial applications. Research the local market to determine which profiles are in demand.

Q2: How do I ensure compatibility with Zimbabwe’s power supply?

A: Verify that the machine supports the power supply standards in your region, either 220V or 380V. Machines with voltage regulation or that are compatible with generators are ideal in areas with inconsistent power.

Q3: Are there financing options for roll forming machines in Zimbabwe?

A: Yes, many international suppliers offer financing options, and some local banks may offer loans for industrial equipment. Check both sources to find flexible financing plans that suit your business needs.

Q4: Is it better to buy a new or used roll forming machine for Zimbabwe’s market?

A: This depends on your budget and production requirements. New machines come with a warranty and latest features but are more expensive. Used machines offer cost savings but may have maintenance needs. Consider your priorities and consult a trusted supplier.

Q5: What should I look for when buying a used roll forming machine?

A: Inspect the machine’s condition, check for any repair history, and ensure that spare parts are readily available. It’s also advisable to test the machine before purchase to confirm it meets your production needs.

Q6: What’s the best way to handle shipping and import for a roll forming machine?

A: Partner with a logistics provider who understands Zimbabwean import regulations. They can help manage customs, shipping insurance, and ensure the machine is delivered safely and efficiently.

Investing in a roll forming machine in Zimbabwe can significantly boost your production capabilities and meet local market demands. Whether you choose a new or used machine, carefully consider the profiles, power requirements, and logistical factors that affect your decision. With the information in this guide, you’ll be well-equipped to make an informed purchase that supports your business goals in Zimbabwe’s dynamic industrial landscape.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.