Posted on Monday, November 4, 2024

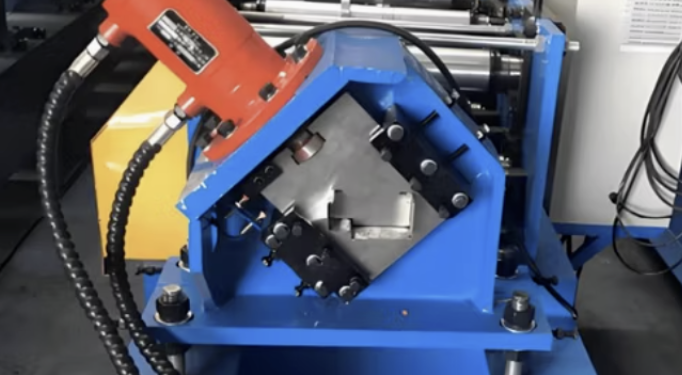

Jordan’s construction sector is expanding rapidly, driven by growing infrastructure projects, urban development, and increased demand for commercial and residential buildings. As the industry evolves, efficient manufacturing and construction processes are becoming essential to keep up with the rising demand. Roll forming machines play a pivotal role in this context by enabling the production of high-quality, customizable building materials. In this blog, we’ll explore how roll forming machines are supporting Jordan’s construction needs, the popular profiles and materials used, and the opportunities and challenges within this market.

Roll forming machines offer unmatched efficiency and speed in producing metal profiles. In the context of Jordan’s growing construction market, speed is critical, especially for large-scale projects with tight timelines. Roll forming machines can produce continuous lengths of precise metal profiles, reducing manufacturing time and allowing construction to progress without delays.

One of the main advantages of roll forming is its cost-effectiveness. By producing profiles in long lengths with minimal waste, roll forming machines lower material costs, saving contractors and developers significant expenses. Moreover, reducing the need for extensive manual labor in manufacturing and assembly helps cut labor costs—a crucial consideration in Jordan, where construction budgets can be tight.

Roll forming machines offer exceptional customizability, making it possible to create profiles suited to specific structural needs. This adaptability is valuable in Jordan’s construction sector, where projects vary widely, from residential buildings to commercial complexes and public infrastructure. Roll forming machines can produce various shapes, such as roofing panels, wall studs, and deck panels, ensuring that every construction requirement is met.

Jordan’s construction sector relies on specific profiles and materials that cater to local needs. Here are some of the most widely used profiles and materials, along with their significance.

Each of these materials and profiles aligns with Jordan’s construction requirements, where quality, durability, and efficiency are paramount.

Roll forming machines are pivotal across multiple industries within Jordan’s construction sector. Here’s a look at the main areas benefiting from these machines:

Jordan’s housing market is expanding to accommodate its growing population. Roll formed products, such as roofing and structural components, are crucial for residential projects, where quick and efficient building methods are essential to meet housing demands. Wall framing, roofing panels, and drywall studs allow contractors to complete projects faster while maintaining quality.

With a rise in urbanization and the establishment of new shopping centers, office buildings, and industrial parks, the demand for commercial buildings is high. Roll formed profiles, like deck panels and structural beams, are extensively used in constructing these structures. The precision and uniformity of roll formed components provide the strength needed for larger structures and ensure long-lasting durability.

Infrastructure projects in Jordan, including bridges, roads, and government buildings, rely on resilient materials to withstand wear and tear. Roll forming machines support the production of robust profiles, such as guardrails and structural steel beams, essential for these public works projects. As Jordan’s government invests in enhancing infrastructure, roll forming technology will play an increasingly vital role.

One example of how roll forming machines are transforming Jordan’s construction sector is Amman Steel, a local company specializing in metal fabrication for residential and commercial projects. To meet the rising demand for durable and customized building materials, Amman Steel invested in state-of-the-art roll forming machines. These machines enabled them to produce high-quality roofing and decking panels tailored to client specifications, reducing material costs and production time. Amman Steel’s success demonstrates the value of roll forming technology in Jordan’s competitive construction landscape, showcasing how companies can leverage this technology to gain a competitive edge.

As Jordan’s construction sector continues to grow, roll forming machines have become essential tools for meeting the industry’s demands. They offer efficiency, cost savings, and the ability to produce customized profiles tailored to Jordan’s unique building needs. With various profiles, from roofing panels to decking systems, and materials like steel and aluminum, roll forming machines are well-suited to support the country’s infrastructure and development goals.

Investing in roll forming technology can lead to higher efficiency, reduced costs, and more sustainable construction practices. As the demand for advanced building solutions increases, roll forming machines will play an even more prominent role in shaping the future of Jordan’s construction industry.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.