Posted on Tuesday, November 19, 2024

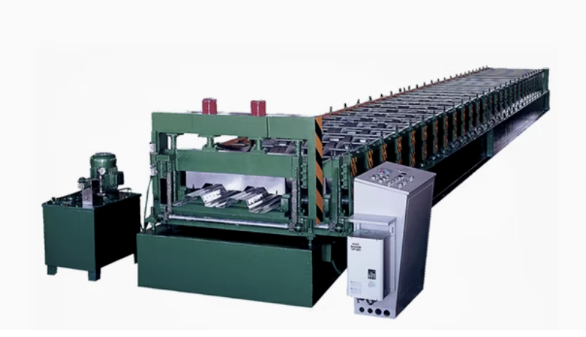

Mozambique's construction industry is experiencing a remarkable boom, fueled by infrastructure projects, urban development, and increasing investments in housing and commercial spaces. As the demand for modern, durable, and cost-efficient construction materials surges, roll forming machines are playing a pivotal role in transforming the industry.

The construction sector in Mozambique is growing rapidly due to:

Roll forming machines are at the forefront of this transformation, enabling the production of high-quality building materials tailored to Mozambique's construction needs. Here’s how:

Roll forming machines produce roofing sheets, wall panels, and structural components faster and more consistently compared to traditional methods. With Mozambique's need for large-scale construction materials, these machines meet deadlines without compromising quality.

Local climate and architectural styles require unique profiles and designs. Roll forming machines allow customization of:

Mass production through roll forming machines minimizes material wastage, reduces labor costs, and ensures affordability, making modern construction materials accessible for local builders and developers.

With the global shift towards sustainable practices, roll forming machines offer an eco-friendly solution. By optimizing raw material use and enabling recyclable steel and aluminum profiles, these machines support Mozambique's green building initiatives.

Roll forming machines produce materials such as lightweight steel profiles that are easy to transport and assemble, ideal for remote areas and rapid urbanization projects.

The production of prefabricated components, such as purlins and trims, is enhanced with roll forming machines, facilitating faster on-site assembly and reduced construction time.

Machines equipped with advanced systems can add protective coatings to materials during production, increasing durability and reducing maintenance needs for structures in Mozambique's tropical climate.

The construction boom in Mozambique is unlocking immense opportunities for roll forming machines to shine as the backbone of the building material production process. These machines are not only driving efficiency and innovation but also empowering the country’s journey toward modern infrastructure and sustainable development. By adopting roll forming technology, Mozambique's construction industry is poised to set a benchmark for growth and resilience in the region.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.