Posted on Tuesday, November 26, 2024

Metal fabrication involves transforming raw metal materials into finished products and structures used across industries. The machines involved in metal fabrication are diverse, each serving specific purposes to ensure precision, efficiency, and durability.

Top 5 Machines Transforming Metal Fabrication in the U.S.

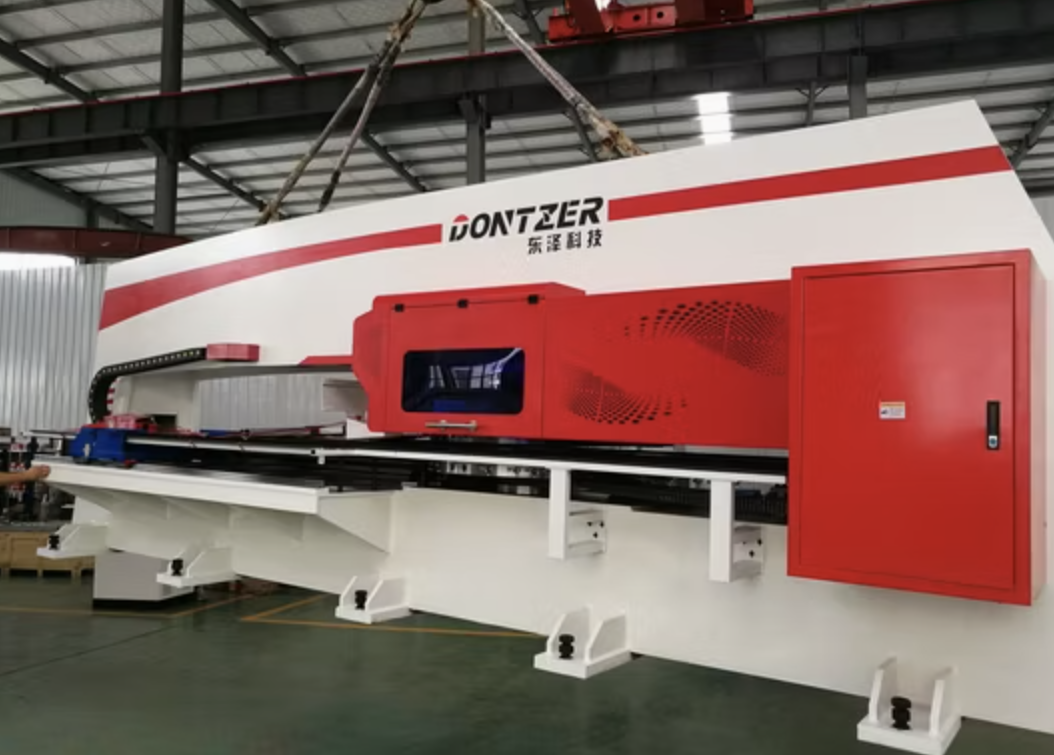

Roll forming machines play a critical role in the U.S. steel industry by offering a highly efficient way to produce consistent and customized steel profiles. These machines are pivotal in manufacturing components for construction, transportation, and infrastructure development.

Plasma and laser cutting machines are indispensable in the metal fabrication process due to their precision and versatility. From cutting intricate designs to shaping industrial parts, these machines cater to both creative and structural needs.

Q: What is the most versatile machine in metal fabrication?

A: CNC machining centers are considered the most versatile due to their ability to perform multiple operations like milling, drilling, and cutting.

Q: How are roll forming machines contributing to sustainable practices?

A: By minimizing material waste and enabling efficient production, roll forming machines support eco-friendly manufacturing processes.

Q: Can laser cutters handle heavy-duty industrial applications?

A: While laser cutters are precise, plasma cutters are better suited for heavy-duty applications involving thick materials.

Metal fabrication in the U.S. is driven by innovation and efficiency. Machines like roll formers, CNC machining centers, and laser cutters are transforming the industry by enabling high-quality, cost-effective, and sustainable production. Whether you're in construction, automotive, or aerospace, these machines are shaping the future of manufacturing.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.