Posted on Monday, November 4, 2024

Denmark’s manufacturing sector is known for its focus on innovation, sustainability, and high-quality products. Metal profiles play a significant role in this industry, particularly within the construction, storage, and logistics sectors. The growing demand for durable, eco-friendly, and efficient building materials has highlighted the importance of roll forming machines, which are essential for producing high-quality profiles that meet market demands. In this blog, we’ll dive into the top profiles used in Denmark and explore how roll forming machines are essential in shaping these products to meet the needs of various industries.

Standing seam panels are highly popular in Denmark, especially in roofing and cladding applications. Known for their sleek aesthetics, durability, and weather resistance, these panels are a preferred choice for architects and builders focused on sustainable construction. Standing seam panels interlock tightly, making them highly resistant to Denmark's windy and often unpredictable climate. Their metal construction also contributes to energy-efficient buildings by reflecting sunlight, reducing indoor cooling costs, and minimizing the environmental impact.

Snaplock panels are another favorite in Danish construction, known for their ease of installation and strong resistance to moisture. The interlocking design provides a clean, modern finish, making them an ideal choice for residential and commercial projects. Snaplock panels are well-suited for Denmark’s aesthetic preferences, which often emphasize minimalism and functionality. Builders favor these panels for their quick installation and secure fit, which ensure both durability and design flexibility.

Roof ridge caps are essential in creating a finished edge on roofs and sealing joints to protect against water ingress. In Denmark, they are commonly used in residential construction, where the focus on energy efficiency and moisture protection is paramount. The demand for ridge caps with unique designs that blend aesthetics and functionality is on the rise, as architects and builders seek options that enhance a building's appearance while offering practical benefits.

With the growth of e-commerce, logistics, and retail in Denmark, the demand for durable storage solutions has surged. Shelf panels are widely used in warehouses, retail spaces, and commercial settings. These profiles need to be lightweight yet strong enough to handle substantial weight, making them ideal for shelving in both small shops and large distribution centers. Danish manufacturers favor materials that are recyclable and environmentally friendly, aligning with Denmark’s sustainability goals.

Apart from the profiles mentioned above, Denmark also uses various structural profiles in construction and infrastructure projects, such as wall panels and floor decking profiles. These profiles are crucial in building frameworks that meet stringent durability and efficiency standards, especially for projects focused on reducing energy consumption.

Several factors drive the demand for these specific profiles in Denmark. First, the country’s focus on sustainable construction has increased the preference for materials that contribute to energy efficiency and environmental responsibility. Durable, recyclable metal profiles align with Denmark’s eco-friendly values and support long-lasting, low-maintenance buildings.

Additionally, Denmark’s climate, which includes a mix of cold, wet winters and warmer, humid summers, necessitates construction materials that can withstand diverse weather conditions. Profiles like standing seam and snaplock panels offer superior protection against moisture and wind, while roof ridge caps add an extra layer of security by sealing roof edges. Danish builders and architects are increasingly drawn to profiles that balance practicality with aesthetic appeal, further fueling demand for versatile and customizable roll-formed profiles.

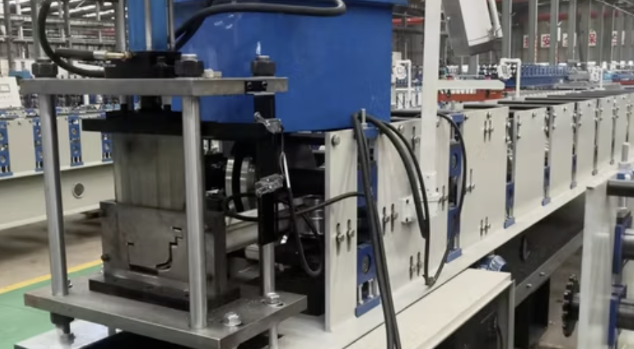

Standing seam roll forming machines are specially designed to handle the precise requirements of standing seam profiles. These machines are equipped with precision rollers and hydraulic cutting systems that ensure smooth edges and consistent dimensions. Customizable settings allow for various panel widths, catering to the unique design needs of each project. With options for additional components like stackers, these machines improve productivity while reducing material waste.

Snaplock roll forming machines offer high-speed production capabilities, essential for meeting the growing demand in Denmark. They allow for easy adjustments to accommodate different panel widths and thicknesses, making them versatile for a range of applications. Many models also come with add-ons like uncoilers and automatic stackers, which streamline the manufacturing process and minimize downtime. With their flexibility and efficiency, snaplock machines are ideal for the fast-paced Danish construction industry.

Roof ridge cap roll forming machines are specialized to create the unique shapes required for ridge caps. These machines are equipped with servo motors, PLC systems, and hydraulic cutting functions to ensure precise shaping and clean cuts. Ridge cap machines cater to the demand for customized designs, allowing manufacturers to produce both standard and unique styles that blend aesthetics and functionality.

Shelf panel roll forming machines are designed to handle various sizes and thicknesses, providing the strength needed for heavy-duty shelving. These machines offer flexibility in production, allowing Danish manufacturers to meet the specific requirements of retail and logistics companies. Additional features like automatic stackers and leveling systems make production more efficient, aligning with Denmark's focus on productivity and eco-friendly practices.

Roll forming machines have become a cornerstone of Denmark’s manufacturing sector. By automating the production of high-quality profiles, these machines improve efficiency and reduce waste, which is vital in Denmark’s eco-conscious market. Roll forming machines support Denmark’s sustainability goals by using minimal energy and generating little scrap. They also enable manufacturers to respond quickly to changing demands, allowing for the production of customized profiles that cater to both aesthetic preferences and structural requirements.

Moreover, roll forming machines incorporate advanced automation features that contribute to worker safety and streamline operations. Automation minimizes manual labor and enhances precision, which is essential for creating profiles that meet Denmark’s strict quality standards. By reducing production time and improving quality, roll forming machines help Danish companies maintain a competitive edge in the global market.

Denmark’s manufacturing sector relies heavily on metal profiles that meet high standards of quality, sustainability, and functionality. Profiles like standing seam panels, snaplock panels, and shelf panels are integral to Denmark’s construction, logistics, and commercial industries. Roll forming machines play a critical role in shaping these profiles, offering Danish manufacturers the tools they need to produce customized, high-quality profiles efficiently.

As Denmark continues to focus on eco-friendly construction and innovative building materials, the demand for specialized roll-formed profiles is expected to grow. Future trends will likely include even greater customization options, improved automation, and further advancements in energy-efficient manufacturing processes. Roll forming technology will undoubtedly remain at the heart of Denmark’s manufacturing landscape, supporting the country’s goals for a sustainable and efficient future.

Machine Matcher – Supplying Quality Roll Forming Machines Worldwide

Machine Matcher is your trusted source for high-quality, affordable roll forming machines, serving customers in the United States, Canada, South America, Africa, the Middle East, and Europe. With a diverse selection of machines to fit any budget, we’re here to meet your manufacturing needs.

Order Process

Each machine is custom-built to meet your specifications. A 50% deposit is required upon ordering, and typical delivery is 4 months from the order date.

Specifications Required

For precise manufacturing, we request a detailed profile drawing with measurements and material gauge, to be approved and signed before production begins.

Shipping & Warranty

Shipping costs are based on the port of origin, and every machine includes a 1-year manufacturer’s guarantee for peace of mind.

Set-Up & Training

For a seamless start-up, our experienced engineers offer on-site setup and operator training at an additional cost.

Check Out Our Machines Today!

Explore our extensive range of roll forming machines and find the perfect fit for your project. Contact us for a quote and take the first step toward enhancing your production capabilities.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.