Posted on Friday, November 15, 2024

Tunisia's construction and manufacturing industries are witnessing significant growth, driving the demand for roll forming profiles. With the country's focus on infrastructure development, housing projects, and industrial expansion, specific roll forming profiles have emerged as essential to meet market needs.

Demand: Roofing sheets are one of the most in-demand profiles in Tunisia due to their widespread use in residential, commercial, and industrial buildings. The country's climate, with its hot summers and occasional heavy rains, necessitates durable and weather-resistant roofing solutions.

Applications:

Materials:

Demand: Cladding panels are gaining popularity in Tunisia for their aesthetic appeal and functional benefits, such as insulation and protection. They are particularly used in modern architecture to create visually appealing facades.

Applications:

Materials:

Demand: Fencing panels are widely used in Tunisia for residential, agricultural, and industrial purposes. Their modular nature and durability make them a practical choice for securing properties and demarcating boundaries.

Applications:

Materials:

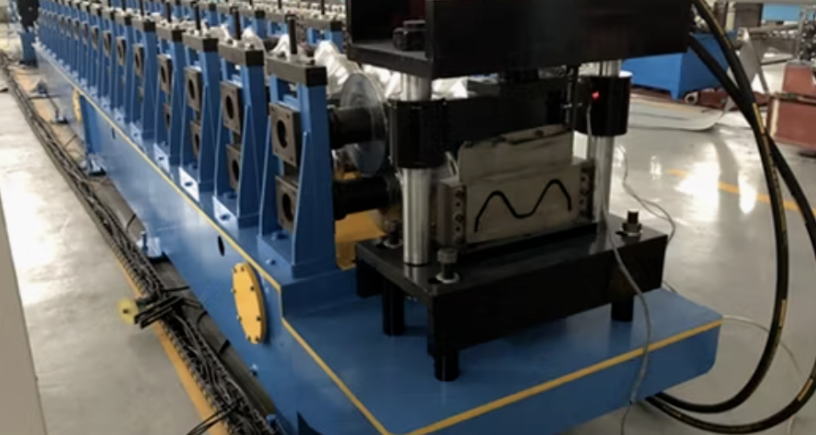

For roll forming machine manufacturers, Tunisia presents a lucrative market to supply machines that produce these profiles. Customizing machines to local requirements, such as specific material gauges and profile dimensions, can help businesses gain a competitive edge.

Suggested Machine Features:

Tunisia's roll forming industry is poised for steady growth as demand for roofing sheets, cladding panels, and fencing panels continues to rise. By understanding the market’s needs, businesses can tap into this opportunity and contribute to the country's development.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.