In the world of modern viticulture, efficiency, durability, and precision are crucial for vineyard infrastructure. Vineyard post roll forming machines have revolutionized the way vineyard posts are manufactured, enabling consistent quality and customization options to meet varying vineyard needs.

1. Overview of Vineyard Post Roll Forming Machines

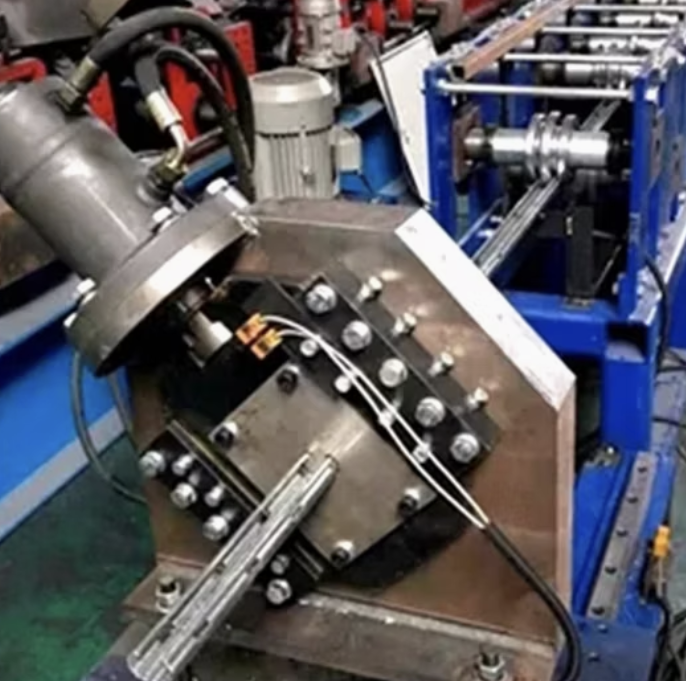

Vineyard post roll forming machines are designed specifically for producing high-strength posts that can support vines in various climates and terrains. This machinery is highly specialized, capable of handling tough materials to produce durable, corrosion-resistant posts that withstand the elements and provide long-term stability. The machine’s design allows for flexibility in size and profile, enabling vineyard managers to customize posts to suit specific vineyard requirements.

2. Key Specifications of Vineyard Post Roll Forming Machines

Each component of a vineyard post roll forming machine contributes to its overall performance. Here’s a breakdown of the specifications that make these machines so effective:

- Roller Materials: The rollers are often made from hardened steel or chrome-coated materials. These materials provide durability and a smooth surface that prevents damage to the metal during the forming process.

- Punching and Notching: Vineyard posts often need holes and slots for mounting, so punching and notching capabilities are essential. These features allow customization of posts to suit different installation and attachment requirements.

- Servo Motors: High-quality servo motors are used for precision control. These motors ensure that each profile is produced with consistency, making adjustments easy and enhancing production efficiency.

- Hydraulic Cutting Systems: The hydraulic cutting system provides clean cuts without warping or damaging the material, an essential feature for producing strong and reliable vineyard posts.

- Frame Size: The robust frame provides stability and supports the machine's operation, especially when handling heavy-gauge materials.

- Motors: High-torque motors power the machine, suitable for continuous operation without overheating, ensuring productivity even in large-scale production runs.

- PLC System: The programmable logic controller (PLC) system automates functions and offers a user-friendly interface, allowing operators to control speed, adjust profiles, and monitor production with ease.

- Machine Speed: Speeds can vary but typically range between 20 and 60 meters per minute, making these machines ideal for high-volume production.

- Safety Guards and Enclosures: Safety is paramount. The machine includes guards and enclosures to protect operators from moving parts and ensure compliance with industry safety standards.

3. Profile Description

Vineyard posts require specific characteristics to meet the demands of the agriculture sector. Here’s a closer look at the profile this machine produces:

- Materials: Common materials for vineyard posts include galvanized steel and aluminum, both known for their durability and resistance to rust and corrosion.

- Sizes: Vineyard posts come in various lengths and widths, depending on the crop and terrain. These machines can produce multiple size profiles to suit different vineyard layouts.

- Material Gauge: Typical gauges range from 1.5 to 3 mm, balancing strength with flexibility. Thicker gauges offer additional strength for areas exposed to strong winds or for supporting heavier vines.

- Market Size: The demand for vineyard posts is substantial, particularly in wine-producing regions with large vineyards requiring robust infrastructure.

- Industries Using the Profile: Primarily used in viticulture, the profile is also beneficial in other agricultural sectors requiring similar support structures.

- Popular Countries and Reasons: This machine is most popular in countries with established viticulture industries, such as France, Italy, the United States, and South Africa. The machine’s versatility and the demand for durable vineyard infrastructure make it a top choice in these regions.

4. Optional Extras and Enhancements

To enhance the machine’s functionality, several extras can be added:

- Stackers: Useful for automatically stacking posts post-production, reducing labor requirements.

- Remote PLC Systems: Allow operators to monitor and control the machine remotely, adding convenience and flexibility.

- Coil Car Tippers: Simplifies the loading and unloading of coils, reducing setup time.

- Uncoilers and Recoilers: Improve material handling efficiency by managing coil feeding and recoiling for continuous production.

- Automatic Stackers: A higher-grade option that organizes profiles immediately after production.

- Leveling System: Ensures the material is fed smoothly, preventing misalignments or bending.

- Coil Handling Systems: Streamline workflow and minimize downtime, particularly useful for larger production facilities.

5. Machine Pricing

Pricing for vineyard post roll forming machines can vary widely depending on configurations, capabilities, and additional features. Here’s a general range:

- Budget Options: $50,000 - $100,000, suitable for small to medium-scale production without extensive automation or extras.

- Mid-Range Options: $100,000 - $200,000, includes additional features like advanced PLC systems and basic automation.

- High-End Options: $200,000 and above, equipped with full automation, remote control capabilities, high-speed production, and top-tier safety features.

6. Setup and Installation

Setting up a vineyard post roll forming machine requires specific steps to ensure smooth operation:

- Space and Power Requirements: Ensure adequate space and stable power supply, as these machines require substantial power, especially at high speeds.

- Initial Assembly: While many machines come partially assembled, professional installation is recommended for optimal setup and calibration.

- Calibration: Calibrate the machine to the required profile specifications before starting production.

- Test Runs: Run initial tests to confirm accuracy and adjust settings as needed to ensure the machine is ready for continuous operation.

7. Maintenance Tips

Regular maintenance is essential for the longevity and performance of your vineyard post roll forming machine:

- Routine Lubrication: Lubricate moving parts to prevent wear and tear, particularly on the rollers and hydraulic system.

- Inspection and Cleaning: Regularly inspect and clean rollers, the PLC system, and sensors to ensure smooth operation.

- Parts Replacement: Monitor and replace components, such as cutters and rollers, as they wear over time.

- PLC System Updates: Keep the PLC software updated to benefit from new features and improved efficiency.

8. Frequently Asked Questions

- Q: What thickness can this machine handle?

A: The machine can typically handle gauges from 1.5 to 3 mm, making it suitable for standard vineyard posts. - Q: Can I customize the post design?

A: Yes, the machine’s punching and notching features allow for custom hole placement and profile designs. - Q: What are the average lead times for machine delivery?

A: Lead times depend on customization, but they generally range from 8 to 12 weeks for fully customized machines. - Q: What power supply does the machine require?

A: The machine typically operates on a three-phase industrial power supply, but specific requirements vary based on the model.

Conclusion

A vineyard post roll forming machine is a valuable investment for vineyard owners and manufacturers, offering customization, durability, and high-speed production for consistent and reliable posts. By understanding the specifications, installation, and maintenance needs of these machines, you can make an informed decision and optimize your production line.

If you’re considering a vineyard post roll forming machine, explore the available options and consult with industry experts to ensure you select the right model for your needs.