Posted on Friday, May 23, 2025

Metal decking is a critical component in modern construction, particularly for buildings that require strength, fire resistance, and cost-effective concrete reinforcement. Whether you're working on commercial floors, industrial mezzanines, or multi-story residential buildings, understanding metal decking types, materials, spans, and manufacturers is key to making informed project decisions.

In this guide, we’ll explore:

Common materials and coatings

Metal deck profile types

Sizing and span capacity

Installation process

Usage with concrete in composite flooring systems

Top manufacturers in the U.S. and globally

Metal decking refers to sheet metal panels, typically galvanized steel, used as structural support for concrete slabs or roofing systems. It acts as a permanent formwork for concrete in composite floor systems and provides lateral stability.

Most metal decking is fabricated from:

Galvanized Steel (G60 or G90 coating): The most common, offering corrosion resistance.

Galvalume (aluminum-zinc coated steel): Enhanced corrosion protection, ideal for coastal or humid climates.

Cold-Rolled Steel: For higher tensile strength applications.

Stainless Steel: For special environments (e.g., chemical plants or marine applications).

Painted Steel or Primed Coated Decking: Often used in visible ceiling systems for aesthetics and additional protection.

Metal deck thickness ranges from:

22 gauge (0.0299") – light-duty

20 gauge (0.0358") – standard for most concrete decking

18 gauge (0.0474") – heavy-duty spans

16 gauge (0.0598") – for long spans or high loads

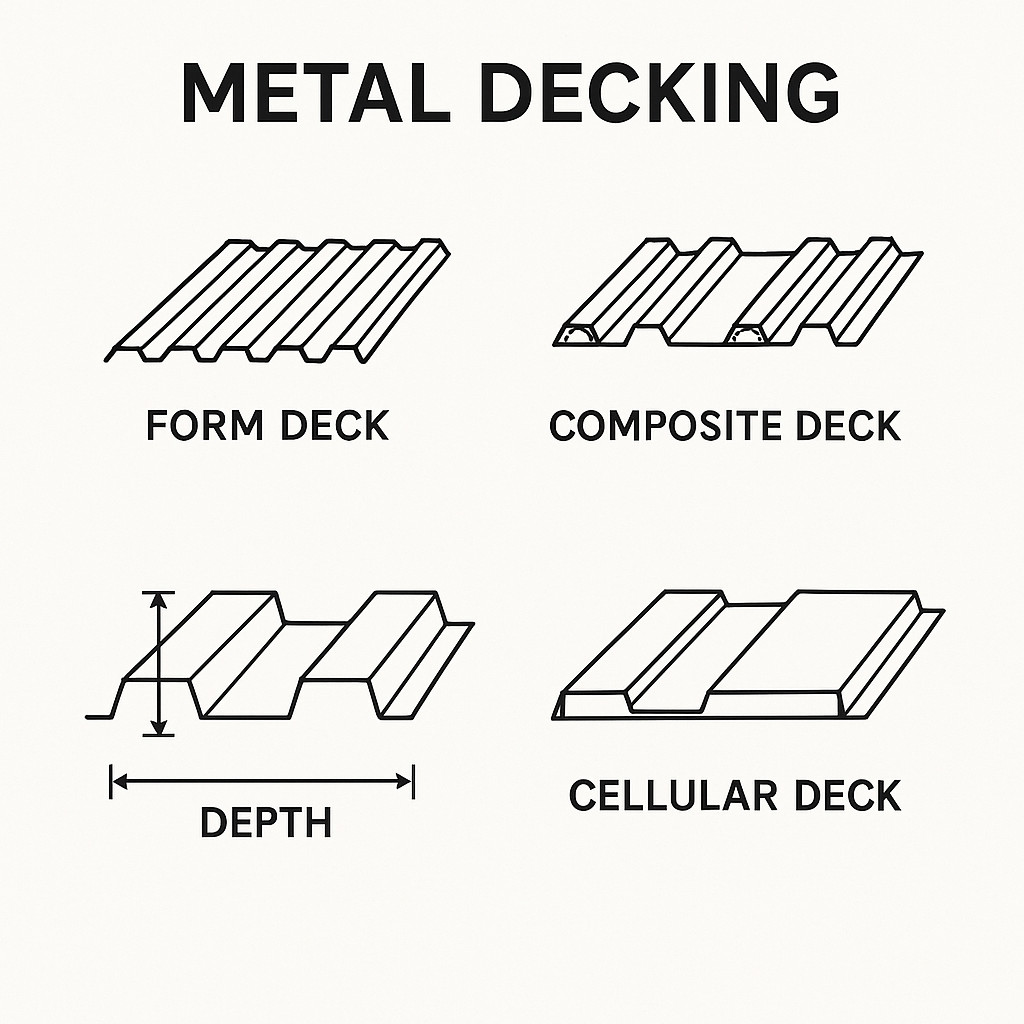

There are three main types of structural metal deck used with concrete:

Used only as a concrete form

Does not bond structurally with concrete

Often used in short-span slab systems

Designed to bond with concrete via embossments and ribs

Carries shear between the steel and concrete slab

Increases load capacity and reduces overall floor thickness

Features a flat bottom surface (used for aesthetics or cable management)

Available as form or composite deck

Can integrate lighting and utilities

Metal decking comes in standardized widths and depths:

| Profile Type | Depth | Cover Width | Typical Gauges |

|---|---|---|---|

| 1.0" Form Deck | 1" | 36" | 22, 20 |

| 1.5" Composite | 1.5" | 36" | 22, 20, 18 |

| 2.0" Composite | 2" | 36" | 22, 20, 18 |

| 3.0" Composite | 3" | 36" | 22, 20, 18, 16 |

| Cellular Deck | 1.5–3" | 36" | 20, 18 |

Span depends on profile depth, gauge, and whether shoring is used. Here's a general guide:

| Deck Profile | Gauge | Max Unshored Span (ft) | Max Shored Span (ft) |

|---|---|---|---|

| 1.5” Composite | 22 | ~5–6 ft | ~8–10 ft |

| 2.0” Composite | 20 | ~6–8 ft | ~10–12 ft |

| 3.0” Composite | 18 | ~9–11 ft | ~12–14 ft |

Always consult manufacturer span tables based on specific concrete thickness and loading conditions.

Layout & Planning

Start with approved drawings. Ensure joists or beams are aligned and ready for deck attachment.

Placing the Deck

Panels are lifted and placed on supports using cranes or forklifts. Workers begin fastening from one end.

Fastening the Panels

Use:

Welds

Screws

Pneumatic pins (like Hilti or Ramset)

Side-Lap Connections

Panels are overlapped and connected using:

Button punch tools

Stitch screws

Shear Stud Installation (for composite decks)

After decking is fastened, shear studs are welded through the deck to connect concrete slab and beams.

Pouring Concrete

Once reinforcement and edge forms are in place, concrete is poured and leveled.

When used in composite systems, metal floor decking forms a key part of a structural slab:

Acts as a working platform during construction

Forms the base for pouring concrete

Bonds with concrete to support live and dead loads

Reduces the need for temporary shoring

Decking can also include embossments to enhance bond strength and cellular sections to accommodate conduits or aesthetic ceilings.

Metal decking is widely used in:

Commercial Buildings (office towers, malls, schools)

Industrial Structures (warehouses, plants, factories)

Residential High-Rises (multistory apartments)

Infrastructure Projects (stadiums, transportation hubs)

Parking Garages (as composite slab formwork)

ASC Steel Deck

New Millennium Building Systems

Canam Steel Corporation

Wheeling-Nisshin

Nucor Building Systems

Verco Decking, Inc.

Centria

ClarkDietrich Building Systems

Cordeck

Metal Deck Supply

Kingspan Group (Ireland)

Tata Steel (UK/India)

BlueScope Steel (Australia)

ArcelorMittal Construction (Luxembourg)

Ruukki Construction (Finland)

Metsec (UK)

JFE Steel Corporation (Japan)

POSCO (South Korea)

SSAB (Sweden)

Bhushan Power & Steel (India)

Dongkuk Steel (South Korea)

HADLEY Group (UK)

Metroll (Australia)

PEMBINAAN PENTA (Malaysia)

Everdeck (UAE)

Zamil Steel (Saudi Arabia)

Kirby Building Systems (Kuwait/India)

Severstal (Russia)

Voestalpine (Austria)

Aluform System GmbH (Germany)

Form deck supports wet concrete only, while composite deck becomes part of the structural slab once cured.

Yes, in roofing applications or mezzanine floors where metal decking alone provides structural support.

Between 0.0299” (22 gauge) and 0.0598” (16 gauge), depending on profile and load requirements.

Galvanized (G90) or Galvalume provides durable corrosion resistance, especially in exposed conditions.

Composite floors may need additional fireproofing depending on building codes, often applied to the underside.

Metal decking is a powerful, efficient solution for concrete flooring systems in commercial, industrial, and multi-residential construction. With numerous profile types, material grades, and design options, understanding how to select and install the right metal deck is essential for structural performance and cost efficiency.

If you’re sourcing metal decking or roll forming machines to manufacture decking profiles, Machine Matcher can help match you with trusted suppliers globally—whether you need raw materials, custom equipment, or full line solutions.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.