Posted on Friday, May 23, 2025

Metal studs are a vital component in modern construction, providing lightweight, fire-resistant, and durable framing systems for both residential and commercial buildings. From interior partitions to complex curtain wall systems, metal studs are widely used across industries. This guide explores everything you need to know about metal studs—including materials, sizes, profiles, installation methods, and a list of the top manufacturers in the USA and globally.

Metal studs are framing components made from cold-formed steel, typically used as a substitute for wood in non-load bearing wall applications and increasingly in load-bearing walls due to improved engineering standards. They are primarily made from galvanized steel and are shaped through roll forming.

Galvanized Steel (G40, G60, G90) – Zinc-coated for corrosion resistance

Stainless Steel – For marine or corrosive environments

Aluminum – Lightweight and corrosion-resistant, but less common

Cold-Rolled Steel (CRS) – Used in high-strength applications

ASTM A653 is the common standard for cold-formed galvanized steel.

Galvanization levels (G40, G60, G90) indicate zinc thickness and corrosion protection.

Optional coatings: epoxy, powder coating, or paint (for custom applications)

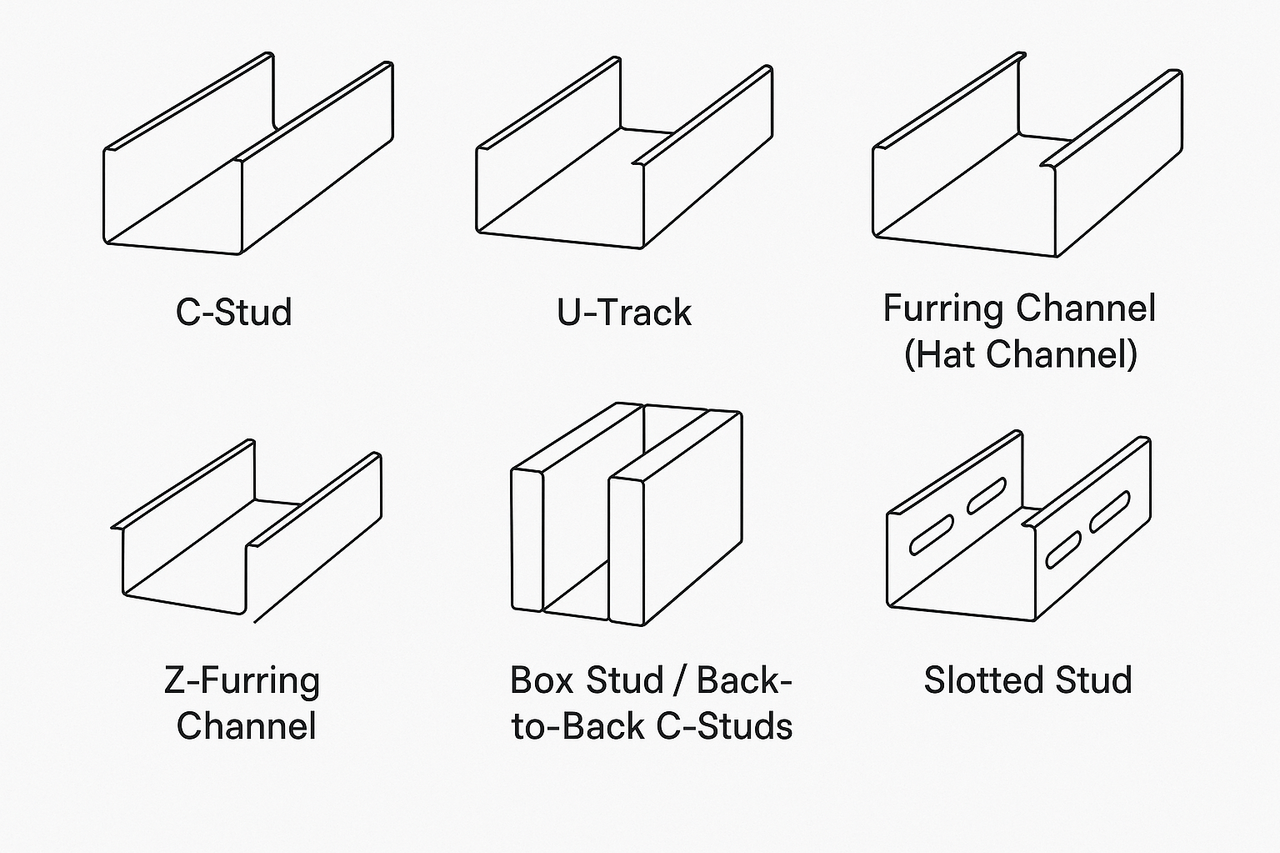

Most commonly used in wall framing.

Available in various flange widths and depths.

Has small return lips for strength and screw anchoring.

Used at the top and bottom of a wall system to receive the studs.

Typically the same width as the stud it supports.

Shaped like a hat, used to fur out walls or ceilings.

Common in acoustic and drywall applications.

Designed for thermal insulation systems and used vertically on walls.

Used for high-load conditions such as wind-bearing or axial-load walls.

Allow vertical deflection movement without affecting wall integrity.

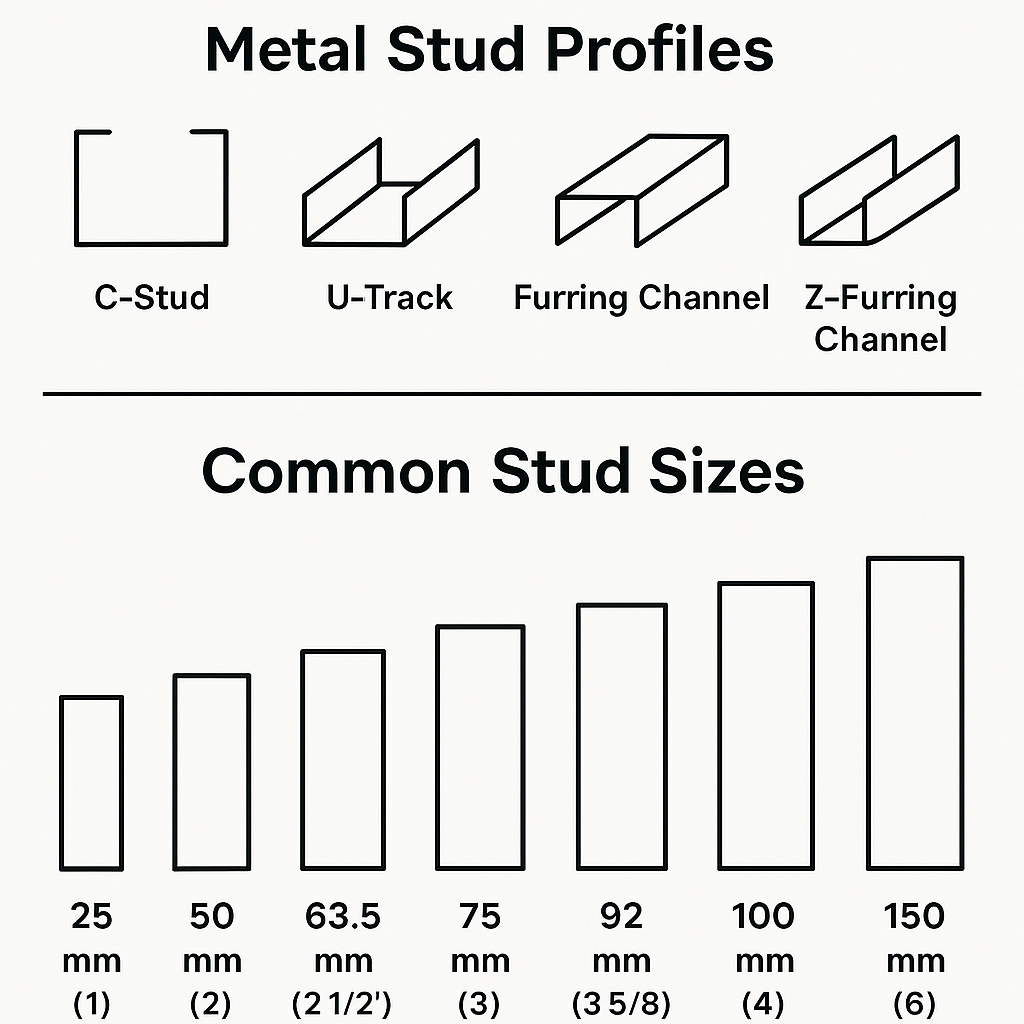

| Stud Width (mm/inch) | Common Applications |

|---|---|

| 25mm / 1" | Light furring, ceiling channels |

| 50mm / 2" | Non-loadbearing walls |

| 63.5mm / 2.5" | Interior partitions |

| 75mm / 3" | Light commercial walls |

| 92mm / 3.625" | Higher sound rating walls |

| 100mm / 4" | Shaft walls and fire-rated partitions |

| 150mm / 6" | High partition or load-bearing systems |

Thickness: 0.4 mm to 2.5 mm (16–25 gauge)

Lengths: Typically 2.4m, 2.7m, 3m, or cut-to-length up to 6m+

Interior partition framing

Curtain wall systems

Soffits and ceilings

Cleanrooms and controlled environments

Warehousing partitions

Steel framing for modular buildings

Office partitions

Retail shopfitting

Hotels and hospitals

Basement wall framing

Drywall support systems

Load-bearing steel framing in multi-story homes

Fire-resistant: Non-combustible material

Durability: No rot, termites, or warping

Consistency: Precision-formed from roll forming machines

Lightweight: Easier to handle and install

Sustainable: 100% recyclable steel

Step 1: Measure and snap lines on the floor and ceiling

Step 2: Secure the bottom and top tracks

Step 3: Cut studs to size and insert into the track

Step 4: Screw studs through track flanges using self-drilling screws

Step 5: Install electrical and plumbing through pre-punched holes

Step 6: Add drywall and finish

ASTM C645 – Non-structural framing

ASTM C955 – Load-bearing steel framing

AISI S240 – North American standard for cold-formed framing

UL Listings – For fire-rated assemblies

| Manufacturer | Headquarters | Notes |

|---|---|---|

| ClarkDietrich | Ohio | Largest in North America, wide product range |

| Marino\WARE | New Jersey | Strong in commercial framing |

| CEMCO | California | Western U.S. leader in metal framing |

| AllSteel & Gypsum Products | Georgia | Known for framing accessories and products |

| Telling Industries | Ohio | Full range of structural/non-structural studs |

| Steel Construction Systems | Florida | Innovative prefabricated steel systems |

| Nucon Steel | Texas | Custom roll formed steel framing |

| Caddy (nVent) | Minnesota | Supplies mounting, bracketing systems |

| Dale/Incor | Texas | Major Gulf Coast supplier |

| TSI Corporations | Maryland | Specializes in curtain wall framing |

| Manufacturer | Country | Key Highlights |

|---|---|---|

| ClarkDietrich | USA | North America market leader |

| Saint-Gobain (Gyproc) | France | Major drywall/stud supplier worldwide |

| Knauf | Germany | Global producer of framing and drywall |

| Fermacell (James Hardie) | Germany | Fire-rated systems and steel profiles |

| Metsec (voestalpine) | UK | Structural framing systems |

| Kingspan Steel | Ireland | Framing and envelope systems |

| USG Boral | Australia | Strong Asia-Pacific footprint |

| Alstrong | India | Metal wall panels and partition framing |

| Everest Industries | India | Pre-engineered and dry construction products |

| JFE Shoji | Japan | Steel processing and distribution |

| Hadley Group | UK | Cold roll forming for global export |

| Baosteel Construction | China | Domestic and overseas projects |

| Boral Steel Framing | Australia | Part of Boral Group (roofing, wall systems) |

| Siniat (Etex Group) | Belgium | Offers full wall systems including studs |

| KNAUF UAE / KNAUF Egypt | UAE/Egypt | Middle East and Africa markets |

| Wuhan Iron & Steel | China | Supplies to construction and infrastructure |

| Framecad | New Zealand | Software-integrated light gauge systems |

| Rondo Building Services | Australia | Commercial stud framing and accessories |

| Tata Steel | UK/India | Framing solutions and coated steel |

| POSCO | South Korea | Steel supply to global manufacturers |

Q: What gauge metal stud is used for load-bearing?

A: Typically 16 to 20 gauge (1.2mm to 1.5mm thick) studs are used for structural load-bearing walls.

Q: Are metal studs cheaper than wood?

A: In many regions, especially in commercial projects, metal studs can be more cost-effective due to durability and lower maintenance.

Q: Can metal studs hold heavy weight like TVs or cabinets?

A: Yes, with proper backing or fasteners, metal studs can support significant weight.

Q: Are metal studs recyclable?

A: Yes, they are 100% recyclable and are often made from recycled steel.

Q: Can you cut metal studs on-site?

A: Yes, using snips for light-gauge studs or power tools for thicker ones.

Metal studs are indispensable in today’s fast-paced construction environment. They offer versatility, precision, and durability across a wide range of industries and projects. Whether you're outfitting a high-rise in New York or installing drywall in a suburban home, metal studs provide a dependable framework for your structure.

For professionals, architects, and contractors looking to source metal studs or framing machines, platforms like Machine Matcher can connect you with trusted manufacturers across the globe.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.