Posted on Monday, September 22, 2025

Modern roll forming machines rely on PLCs (Programmable Logic Controllers) to automate coil feeding, forming, cutting, and punching. If you’re an operator, engineer, or maintenance technician, understanding how PLC programming works can save downtime, improve productivity, and keep your line safe.

This guide walks through the basics — from whether you really need coding skills, to examples in the three most common PLC languages used in roll forming.

Not always. It depends on the type of change you’re making:

Simple adjustments (no coding needed):

Cut length

Punch spacing

Machine speed

Batch quantities

👉 These are done on the HMI (touchscreen) and don’t require editing the PLC program.

Complex changes (coding required):

Adding a new punching head or forming station

Changing cut-to-length logic

Integrating servo drives or sensors

Modifying safety interlocks

👉 These require reprogramming the PLC with vendor software (e.g., Siemens TIA Portal, Rockwell Studio 5000).

PLCs don’t run on Python or Java. They use IEC 61131-3 industrial languages.

Looks like an electrical relay diagram.

Easiest for electricians and machine operators.

Common for safety and sequencing.

Uses blocks connected by wires.

Great for timers, counters, and encoders.

Text-based, like Pascal or BASIC.

Best for math, servo control, and advanced cut optimization.

(There’s also Sequential Function Chart and Instruction List, but they’re less common in roll forming.)

Here’s a simplified cycle we’ll program three different ways:

Press Start → machine runs.

Motor feeds coil through rollers.

Encoder measures length.

When target length is reached → cutter fires.

Cycle repeats until Stop/E-Stop is pressed.

| Start PB Stop PB E-Stop Run Latch

|----||-------|/|-------|/|-----------------( M0.0 ) |

| Run Latch Roll Motor

|----||----------------------------------------( Q0.0 ) |

| Run Latch Length Reached Cutter

|----||---------||-----------------------------( Q0.1 ) |

| Cutter Reset Counter

|----||----------------------------------------( R C1 ) |

🔍 How to read it:

Start button energizes the “Run Latch.”

Run latch drives the motor.

When length is reached, cutter fires.

Counter resets for next cycle.

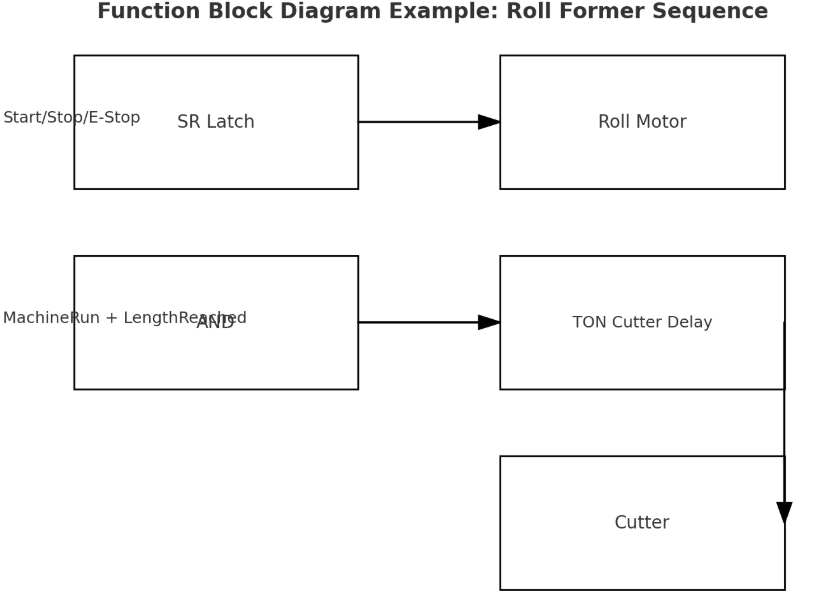

[Start] --->(S) SR (R)<---[Stop/E-Stop]

|

v

MachineRun ----> RollMotor (Q0.0)

MachineRun ----> AND ----> [LengthReached] ----> TON (CutterDelay)

|

v

Cutter (Q0.1)

Cutter ----> CTU (BatchCounter)

🔍 How to read it:

SR latch holds the machine run signal.

AND block ensures cutter only fires when running and length is reached.

TON block delays the cutter output for smooth operation.

CTU counts cuts toward batch quantity.

// Machine Run Latch

IF Start AND NOT Stop AND NOT EStop THEN

MachineRun := TRUE;

END_IF;

IF Stop OR EStop THEN

MachineRun := FALSE;

END_IF;

// Motor Control

RollMotor := MachineRun;

// Cutter Control

IF MachineRun AND LengthReached THEN

CutterTimer(IN := TRUE, PT := T#500MS);

ELSE

CutterTimer(IN := FALSE);

END_IF;

Cutter := CutterTimer.Q;

// Batch Counting

IF Cutter THEN

BatchCounter(CU := TRUE, PV := 100);

ELSE

BatchCounter(CU := FALSE);

END_IF;

IF BatchCounter.Q THEN

MachineRun := FALSE;

END_IF;

🔍 How to read it:

If Start is pressed, the machine runs until Stop/E-Stop is pressed.

Motor runs when MachineRun is true.

Cutter fires for 0.5s when length is reached.

Counter tracks parts cut, and stops the machine after the batch is complete.

✅ Back up before changes – always save the original program.

✅ Don’t bypass safety – E-stops, guards, and interlocks must stay active.

✅ Test step by step – check motor, cutter, and counter separately.

✅ Use the right language for the job – Ladder for safety, FBD for timing, ST for advanced servo logic.

✅ Document everything – update I/O maps and save final versions.

Simple changes like adjusting cut lengths can be done by operators via HMI. But logic changes, servo integration, or troubleshooting crashes should be left to trained PLC engineers. Mistakes in programming can cause coil waste, tooling damage, or safety risks.

Reprogramming a PLC on a roll forming machine doesn’t always mean “coding.” Sometimes it’s just entering new values on the touchscreen. But when it does involve programming, knowing how Ladder, FBD, and Structured Text work will help you understand what’s happening behind the scenes.

Whether you’re adjusting parameters or developing full automation logic, always prioritize safety, documentation, and testing.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.