Posted on Sunday, September 28, 2025

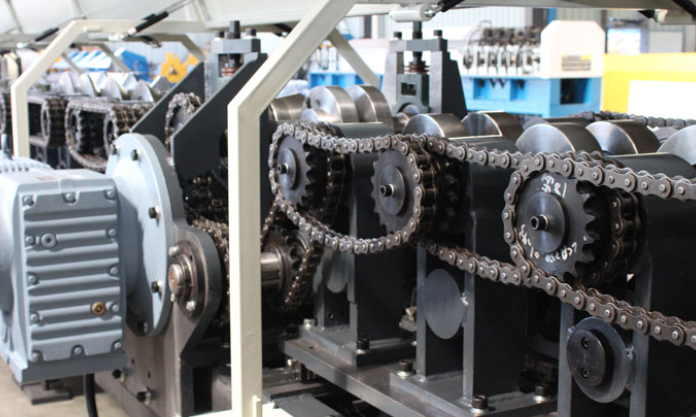

A slipping chain on a roll forming machine is one of those issues that can quietly disrupt operations, reduce efficiency, and even damage other components if left unaddressed. Understanding what causes it, how to spot early warning signs, and how to repair it is essential for every operator and maintenance team. In this guide, we’ll explore the causes, inspection tips, and practical repair ideas to keep your roll forming machine running smoothly.

Most roll forming machines rely on a chain drive system to transmit power from the motor or gearbox to the rollers. The chain ensures that the rollers rotate in sync to shape metal sheets or profiles accurately. When the chain begins to slip, it can result in:

Uneven or inconsistent panel formation

Excessive noise from the drive system

Visible skipping over sprocket teeth

Jerky or irregular machine movement

Left untreated, a slipping chain can compromise product quality and cause additional wear on gears, bearings, and other drive components.

Chains and sprockets are powerful and can cause injury if mishandled. Before any inspection or repair:

Turn off the machine and engage lockout/tagout (LOTO) procedures.

Ensure all moving parts have stopped completely.

Wear gloves and eye protection, as chains often have sharp edges.

Keep the work area clean to prevent accidents.

Never skip safety—many minor chain issues can quickly become hazardous if the machine starts unexpectedly.

Chain slipping generally results from wear, misalignment, or improper maintenance. The most frequent causes include:

Chains naturally stretch over time. Look for:

Elongated links or visible gaps

Loose or stiff links

Measurements exceeding manufacturer specifications

When chain elongation is beyond tolerance, replacement is usually the safest solution.

Sprockets wear in tandem with chains. Common symptoms of worn sprockets include:

Teeth that appear hooked, sharp, or uneven

Noise during operation

Chains skipping over certain teeth

Even minor wear can reduce efficiency. Replacing worn sprockets is typically preferable to attempting minor repairs.

Chains that flap or jump often suffer from improper tension. Causes may include:

Faulty tensioners

Loose mounting points

Natural vibration over time

Check the chain sag and adjust tensioners according to the machine manual.

Even a properly tensioned chain can slip if sprockets are misaligned. Misalignment may result from:

Shifted frames

Loose bolts

Incorrect installation

Use a straight edge or laser alignment tool to confirm alignment both horizontally and vertically.

Chains need lubrication to run smoothly. Signs of insufficient lubrication include:

Squeaking or grinding noises

Rust or dryness on the chain

Rapid wear or sticking

Regularly applying a high-quality industrial chain lubricant is essential for longevity.

Once you’ve identified the cause of slipping, the following solutions can restore optimal performance:

If the chain is stretched, damaged, or worn beyond tolerance, replace it. Make sure the replacement matches the required pitch, width, and type for your machine.

Replace worn sprockets to maintain proper engagement with the chain. Filing or cleaning minor wear is possible, but replacement is usually safer and more effective.

Loosen motor or driven shaft mounts and adjust sprockets to ensure the chain runs straight. Proper alignment minimizes wear and reduces the chance of further slipping.

Follow manufacturer guidelines to set the correct chain tension. Tension should prevent slipping without overloading bearings or shafts.

Use lubricants designed for your operating temperature and environment. Consistent lubrication reduces friction and extends chain life.

Loose bolts or brackets can cause misalignment and chain slippage. Regularly check mounting points and tighten as needed.

| Symptom | Possible Cause | Immediate Action |

|---|---|---|

| Chain skips teeth | Worn chain, worn sprocket, misalignment | Inspect chain length, check sprockets, realign |

| Noise during operation | Lack of lubrication, misalignment | Lubricate chain, align sprockets |

| Uneven profiles | Slipping chain | Check tension, inspect chain and sprockets |

| Visible chain sag | Loose tension | Adjust tensioner or replace tension spring |

Proactive maintenance can prevent chain slipping and extend the lifespan of your roll forming machine:

Inspect chains and sprockets every 500–1000 operating hours.

Lubricate chains weekly or as recommended.

Keep the chain area free from debris.

Maintain a record of inspections, replacements, and adjustments.

Avoid exceeding machine design capacity to prevent excessive wear.

Slipping chains usually stem from wear, misalignment, or tension issues.

Regular inspection, proper lubrication, and correct alignment are critical for preventing problems.

When repairing, always follow safety procedures and manufacturer guidelines.

Timely replacement of worn chains or sprockets ensures consistent product quality and prevents secondary damage.

By understanding the causes and solutions for a slipping chain, roll forming machine operators can maintain optimal performance, reduce downtime, and protect their investment in machinery.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.