Posted on Saturday, September 27, 2025

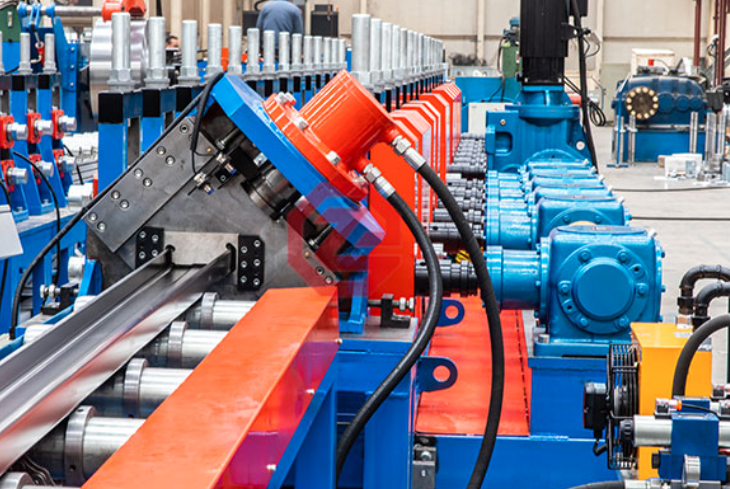

A roll forming machine relies on precise power transmission to deliver consistent profiles, high productivity, and long-term reliability. At the heart of this process is the gearbox, which transfers torque from the motor to the forming rollers. When a gearbox begins to slip, it can compromise product quality, cause machine downtime, and even lead to costly damage if left unresolved.

The gearbox is a mechanical assembly that adjusts speed and torque between the drive motor and the rollers of the machine. In roll forming, the gearbox ensures that every roller station turns in harmony, forming metal sheet or coil into the desired profile without distortion.

A slipping gearbox occurs when the internal gears or coupling surfaces fail to transmit full power. Instead of engaging firmly, they “slip,” causing reduced torque, uneven roller speed, or even complete loss of motion in certain stations.

Product Quality Issues: Misformed panels, uneven dimensions, and visible defects in roofing, cladding, or structural profiles.

Increased Wear: Slippage puts strain on other components such as bearings, chains, and motors.

Downtime and Cost: A failing gearbox can halt production and require expensive repair or replacement.

Safety Risks: Uncontrolled movement or mechanical binding can pose hazards to operators.

Cause: Worn gear teeth, misalignment, or insufficient lubrication.

Solution: Inspect gears for wear, check shaft alignment, and refill or replace gearbox oil.

Cause: Damaged bearings, broken gear teeth, or contamination inside the gearbox.

Solution: Open the housing, replace faulty bearings/gears, and flush before refilling with clean oil.

Cause: Low oil levels, poor lubrication, or excessive load.

Solution: Top up/change oil, ensure correct viscosity, and check for overload or binding.

Cause: Slipping clutches, stripped gears, or loose couplings.

Solution: Replace clutches/gears, tighten or realign couplings.

Cause: Worn or damaged seals.

Solution: Replace seals and gaskets, refill with the recommended lubricant.

Operators can use this step-by-step checklist for fast diagnosis and corrective action:

☐ Listen for unusual noises (grinding, knocking, clunking)

☐ Check gearbox oil sight glass or dipstick (top up if low)

☐ Inspect casing for leaks or overheating

☐ Ensure couplings and fasteners are tight

☐ Check for vibration or jerky roller movement

☐ Inspect shaft alignment and chain/belt tension

☐ Verify that all safety guards and covers are secure

☐ Drain a small oil sample – check for metal particles or contamination

☐ Inspect external seals and gaskets for wear

☐ Clean around breather caps and vents to prevent dust ingress

Shut down & lock out power supply.

Inspect external couplings and chain/belt tension.

Open gearbox housing and check:

Gear teeth condition

Bearings and shafts

Seals and lubrication levels

Replace damaged components (gears, bearings, seals, or clutches).

Flush housing and refill with manufacturer-recommended oil.

Reassemble gearbox and test under no load.

Gradually increase load while monitoring for noise, vibration, or heat.

Regular Oil Changes: Follow the manufacturer’s service schedule.

Routine Inspections: Check gears, bearings, and seals regularly.

Correct Loading: Do not exceed the machine’s rated material thickness.

Proper Alignment: Keep shafts and couplings aligned to reduce strain.

Monitor Vibration: Early changes in vibration can signal internal wear.

A slipping gearbox on a roll forming machine should never be ignored. By paying attention to early symptoms and using a clear inspection checklist, you can prevent costly downtime and extend the life of your machine.

If your roll forming machine is experiencing gearbox issues and you need help sourcing replacement parts or expert guidance, Machine Matcher can assist. Our team specializes in machine support, inspections, and supplying new roll forming equipment tailored to your needs.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.