Posted on Monday, September 29, 2025

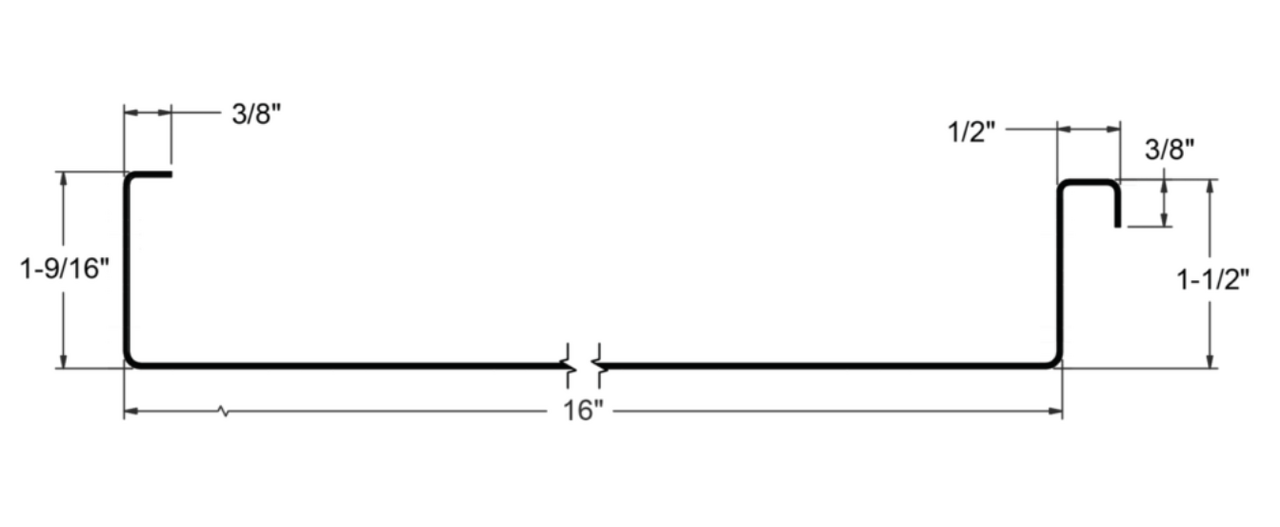

Standing seam metal roofing has become something of a “go-to” for architects, contractors, and homeowners aiming for durability, aesthetics, and low maintenance. But “standing seam” is not a single product — it’s a family of panel styles, dimensions, gauges, and seam types. In this post, we’ll explore what panel styles and sizes are most popular in the U.S., how regional climate influences those choices, and include a sample profile drawing to help you visualize what we’re talking about.

Before we dive into numbers, let’s define what “popular” means in this context. A panel style or size becomes popular when it hits a sweet spot of:

Performance (wind uplift resistance, leak prevention, structural strength)

Cost efficiency (material cost, ease of installation, waste)

Aesthetics (clean lines, pleasing proportions)

Availability / manufacturability (ease to roll-form, standard coil widths)

Because of these trade-offs, you’ll often see certain panel dimensions and styles repeated across many projects.

Here are some of the “go-to” or “most used” spec ranges for standing seam metal roofing in the U.S.:

| Parameter | Common / Popular Range | Notes & Examples |

|---|---|---|

| Panel (exposed) Width | ~12″ to 18″, with 16″ very common | Many manufacturers list 12″, 16″, 18″ widths. MBCI+2Copper Development Association+2 |

| Seam / Rib (vertical leg) Height | ~1″ to 2″ | E.g. MBCI LokSeam has a 1⅞″ rib (1.75 in) in many cases. MBCI+1 |

| Metal Gauge / Thickness | 22 to 26 gauge, with 24 gauge being the “standard sweet spot” | 24 gauge is thick enough for strength but still economical. Sheffield Metals+2Western States Metal Roofing+2 |

| Panel Length | Custom / cut-to-length; can go very long (30 ft, 40 ft, 50 ft, depending on manufacturer) | Many roofs use field roll forming or factory lengths tailored to the building span. |

| Fastening / Seam Type | Concealed clips + either snap-lock or mechanically seamed (single lock / double lock) | Snap locks are faster to install; mechanical seams are more robust, especially in extreme weather. Sheffield Metals+3Western States Metal Roofing+3McElroy Metal+3 |

| Minimum Slope | ~2:12 to 3:12 (varies by profile) | Some highly engineered structural panels can go down to ~1:12 in extreme cases. McElroy Metal+1 |

A frequently seen “typical” (but not universal) specification is: 16″ wide exposure, ~1.75″ rib height, 24 gauge, snap-lock with concealed clips.

The “best” or “most used” panel in, say, Florida is different from what you might choose in Idaho or Minnesota. Here’s how region changes things:

High wind (hurricane) zones — uplift resistance is critical

Greater concern for corrosion, salt, UV exposure

Preference for heavier gauge (24 ga or even 22 ga when needed)

Panels must often meet strict building code / product approval (e.g. Florida product approvals)

Efficient installation (snap-lock) helps control labor in humid conditions

In Florida specifically, you’ll see panels that carry Florida product approval (e.g. the 16″ standing seam “Minor Rib” version is cited as having Florida approval. Metal Roofing Source

Snow loads, freeze-thaw cycles, thermal movement take priority

Mechanical seam (double-lock) more common, especially for steeper slopes

Heavy gauge (thicker than 24 ga) sometimes used

Rib height may be higher to help shed snow and standing water

Very high wind, sometimes extreme loads, wide temperature swings

Materials with strong coatings (for corrosion resistance under UV)

More frequent use of custom / engineered panels

In milder climates, 26 ga might suffice in many places; in more extreme climates, 24 or even 22 ga is safer. Western States Metal Roofing+2Western States Metal Roofing+2

Panels with striations or stiffening ribs are often used to reduce “oil canning” (visual distortion) especially in wider panels. Sheffield Metals+1

In coastal or salt exposure zones, premium coatings (PVDF / Kynar) and attention to galvanic isolation are common additional specification constraints.

If I were to pick what people in Florida / Gulf Coast region often choose (or target), it might be:

16″ exposed width

~1.75″ vertical rib height

24 gauge Galvalume or painted steel

Snap-lock (concealed clip)

PVDF / Kynar 500 finish (for durability in sun / salt)

Field-formed or factory-cut to length

In contrast, in a Northern snowbelt region, you might often see:

12″ or 16″ widths

2″ rib height

24 ga, sometimes 22 ga

Double-lock mechanical seams in higher exposure locations

More robust warranties and thicker coatings

Span & engineering: Longer spans or heavier snow/wind loads may require narrower panels or stronger seams.

Oil canning: Wider panels (e.g. 18″ or more) are more prone to visible waviness; using stiffening ribs or striations helps.

Installation speed: Snap-lock is faster (less labor) than mechanical seaming.

Climate & exposure: In coastal, high-wind, or hail zones, err on the side of stronger/gauge and high-quality coatings.

Panel length & waste: Custom lengths reduce seams and waste if the panel lengths are well optimized.

Aesthetic proportions: The visual spacing of ribs relative to building scale matters — sometimes designers prefer narrower exposed widths for a particular look.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.