Posted on Monday, September 22, 2025

If you’ve just connected your roll forming machine to a three-phase power supply and noticed that the rollers are turning in the wrong direction, you are not alone. This is one of the most common electrical issues operators encounter during installation or relocation of equipment. The good news is that it is easy to diagnose and even easier to fix.

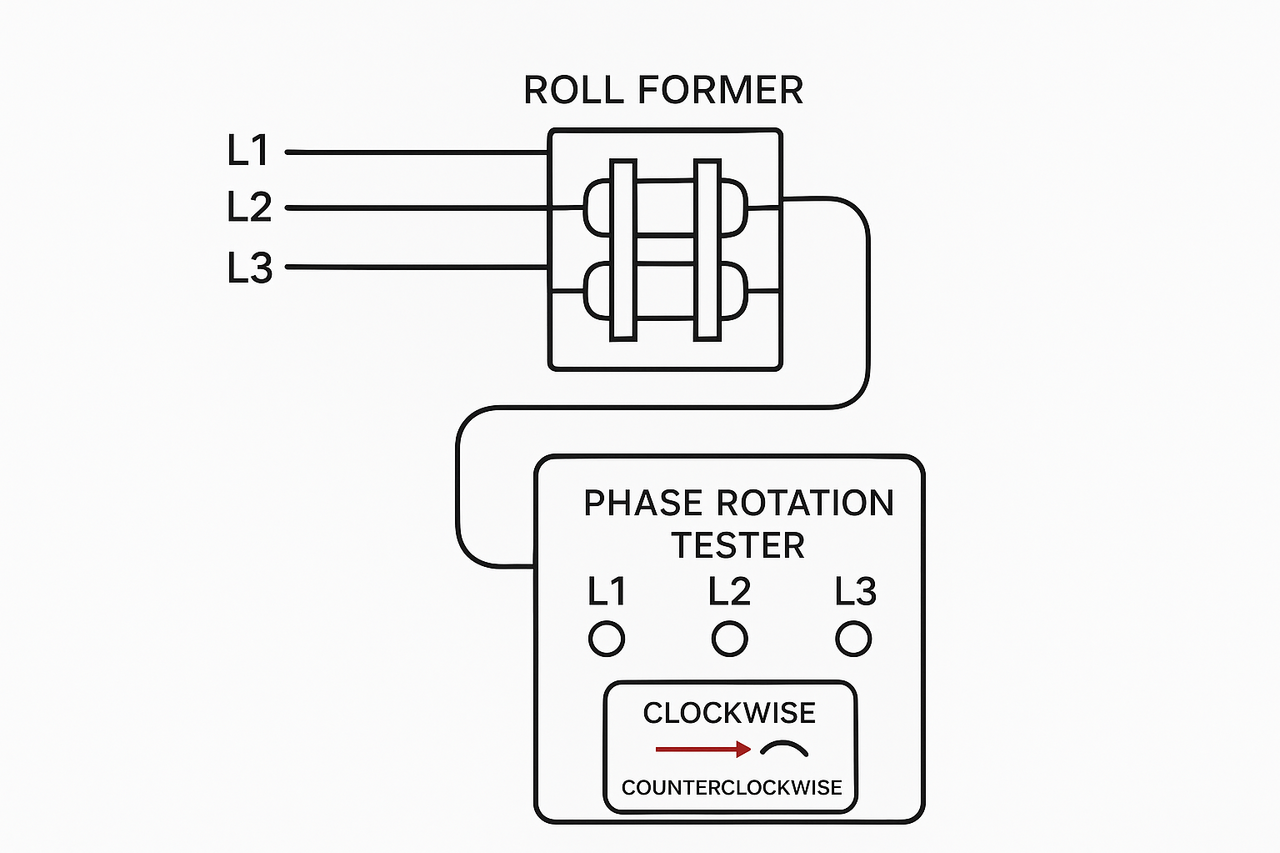

Three-phase motors, which power most industrial roll forming lines, depend on the order of the incoming phases (L1, L2, L3) to determine the direction of rotation. This order is called the phase sequence.

If two of the three supply wires are connected in the wrong order, the motor will rotate backwards. That means your roll former rollers will turn in reverse — pulling material the wrong way or preventing the machine from feeding correctly.

This is not a fault with the motor or the roll former itself. It is simply an electrical connection issue.

Rollers turning backwards when the motor starts.

Material being pushed out instead of fed in.

No warning alarms or unusual motor noises.

Everything else on the machine appears normal.

There are two main ways to check phase rotation:

Connect the tester probes to the three supply phases (L1, L2, L3).

Switch the supply on (but keep the machine off).

The tester will show Clockwise (correct) or Counterclockwise (reverse).

Briefly jog the motor and observe the roller direction.

If they move backwards, the phases are out of order.

⚠️ Always isolate power and follow safety procedures before touching wiring. Only qualified electricians should carry out electrical work.

Power down and lock out the machine.

Open the incoming supply terminal box.

Swap any two of the three supply leads (e.g., L1 and L2).

Close the panel securely.

Restore power and jog the motor.

Rollers should now rotate in the correct forward direction.

If not, repeat the swap until the machine runs as expected.

Mark the correct phase sequence once it’s set, to avoid confusion during future reconnections.

If your roll former uses a VFD (variable frequency drive), the motor direction can often be changed through programming instead of rewiring.

Double-check the forward/reverse switch (if installed) before swapping wires.

Rollers turning wrong way? → Phase rotation issue.

Solution → Swap any two supply phases.

Always test rotation after rewiring.

Label wires for future reference.

Incorrect roller rotation on a three-phase roll forming machine is one of the simplest problems to fix, but it can cause major downtime if not addressed quickly. By understanding phase rotation and following the steps above, you can restore proper operation in minutes.

At Machine Matcher, we support customers with both new and used roll forming equipment worldwide. Our team not only matches buyers with the right machines but also helps ensure smooth installation and operation.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.