Posted on Sunday, October 5, 2025

Roll-forming machines are precision mechanical systems — their productivity depends on the condition of tooling (rollers), drive components, cutting blades, and control electronics. When a part wears or fails, downtime is expensive. This guide explains the most common spare parts, how to identify the exact item you need, and a step-by-step global ordering process so you can get the right part fast — whether it’s an OEM roller set from Bradbury in the U.S., a shear blade for a CUNMAC machine, or an aftermarket replacement from Roll-Kraft.

Common spare parts (what they are and why they fail)

How to identify the exact spare you need (drawings, part numbers, measurements)

Manufacturer vs aftermarket parts — pros & cons

How to order from manufacturers worldwide — step-by-step

Customs, HS codes, shipping, taxes, and lead time strategies

Manufacturer listing template (ready to fill)

Example manufacturer mini-profiles + common spares (6 examples with sources)

Maintenance & spare-parts inventory best practices

SEO & content ideas to attract spare-parts buyers

FAQ

Most roll-forming lines need the following categories of spares:

Rollers / tooling sets — the forming dies that shape the metal; wear changes profile accuracy. (roll tooling is the most specialized, often custom-machined). Machine Matcher

Shafts, keys, and couplings — transfer torque between gearboxes and rollers; fatigue or key shear is common. Roll-Kraft

Bearings & bearing housings — support rotating shafts; contamination and lubrication issues cause failure. Machine Matcher

Drive components: motors, gearboxes, belts, chains — powertrain wear or gear teeth failure. Roll-Kraft

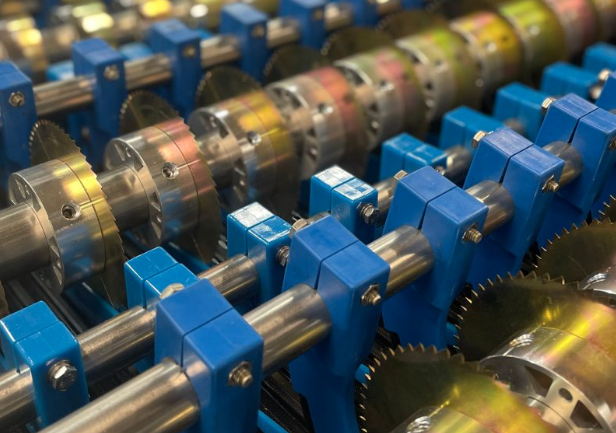

Cutting blades / shear systems — replace when chipped/dull to avoid burrs and scrap. Machine Matcher

PLC, HMIs, encoders, drives (VFDs) — control electronics and feedback devices. Keep model numbers and firmware versions. Machine Matcher

Hydraulic components: pumps, valves, cylinders, seals — seals and valves are common service parts.

Sensors & pneumatics: proximity sensors, cylinders, solenoids — inexpensive but critical for operation.

Fasteners, guards, covers, guide rails — small parts that cause safety or alignment problems when missing.

(Each of the above categories should be accompanied by part numbers, drawings, and photos when you place your order.)

Always collect this minimum data before contacting a supplier:

Manufacturer & model number (plate or docs).

Serial number — many OEMs cross-reference parts by serial.

Part number printed on the part or in the spare parts manual.

Clear photos of both sides of the part (include scale / measuring tape).

Critical dimensions (shaft diameter, key size, tooth count, roller OD/width, hole patterns).

Material / hardness if roller or die (e.g., hardened tool steel, nitrided).

Electrical data for motors/drive modules (voltage, phase, rpm, encoder type).

Operating environment (salt spray, high humidity, abrasive materials), so vendor can recommend coatings.

Tip: a short video of the failing behavior (audio helps for bearings/gearbox noise) speeds diagnosis.

OEM parts: expensive but guaranteed fit, recommended for rollers/tooling and electronics. OEM support pages and service networks exist for major brands. (Examples: Bradbury, CUNMAC, HGG offer local service/support). Bradbury Group+2Cunmac+2

Aftermarket / replacement: often faster and cheaper (companies like Roll-Kraft produce cross-brand spares), ideal for generic items (bearings, belts, simple gears). But check tolerances and material specs. Roll-Kraft+1

Prepare a parts request document (see template below).

Email the OEM parts department with photos, serial, model, and desired delivery time. For urgent parts, request “expedite” and confirm shipping options. (Use OEM support pages to find contacts). HGG Group+1

Is this the exact OEM part number for my serial number?

Is the part new/OEM or remanufactured? Warranty?

Exact lead time, shipping method, and Incoterm.

Can the part be serialized? Any calibration needed?

Confirm compatibility: For tooling/rollers ask about tolerances and materials. For electrical parts ask firmware and connector compatibility.

Get a formal quote with the line-item HS code (for customs), total price, and payment terms.

Place the order with PO that includes full ship-to details, contact, and technical contact. Retain the OEM quotation for customs.

Track and inspect on arrival: verify serials, perform incoming inspection checks and photograph items before installation.

Dispose or return: for returns follow OEM RMA policy; for exchanges agree on core charges if remanufactured.

Request the HS/HTS code on the vendor quote — this speeds customs clearance and tax calculation.

For critical spares, use air freight and choose a customs broker that knows machinery parts.

Consider local stocking of high-failure items: rollers (spare set), bearings, shear blades, and seals.

If lead times are long from the OEM, identify an approved aftermarket supplier that can deliver faster.

BRADBURY, headquartered in Kansas, USA, is a leading manufacturer serving industries such as roofing, construction, and metal framing. Renowned for precision engineering, durability, and high-speed roll forming solutions, BRADBURY produces machines capable of creating a wide range of metal profiles, including roofing panels, wall cladding, and structural sections.

Common BRADBURY roll forming machine parts include rollers, shafts, bearings, shear blades, hydraulic components, PLC/control cards, gearboxes, and other essential tooling. These components are designed to ensure smooth operation, extend machine life, and reduce production downtime. Replacement parts for BRADBURY roll formers are available worldwide, with ordering options supporting global shipping and distributor networks.

Whether you need to order BRADBURY spares, buy BRADBURY tooling, or source replacement parts for BRADBURY roll formers, our directory connects you with the right components quickly and efficiently. Visit the full spare parts page to explore the complete range of BRADBURY roll forming machine parts. View more

Samco Machinery, headquartered in Toronto, Canada, is a leading provider of custom roll forming solutions for industries including metal roofing, construction, automotive, and solar energy. Known for precision engineering and high-speed production, Samco machines create a wide range of metal profiles, including framing, decking, and structural components.

Common Samco roll forming machine parts available in Toronto and worldwide include rollers, shafts, bearings, shear blades, hydraulic components, PLC/control cards, gearboxes, and other essential tooling. These replacement parts are engineered to ensure smooth operation, maximize machine life, and minimize downtime.

Whether you are looking to order Samco spares in Canada, buy Samco tooling, or source replacement parts for Samco roll formers, our directory connects you with reliable suppliers and worldwide shipping options. Visit the full spare parts page to explore the complete range of Samco roll forming machine parts.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.