Posted on Tuesday, October 21, 2025

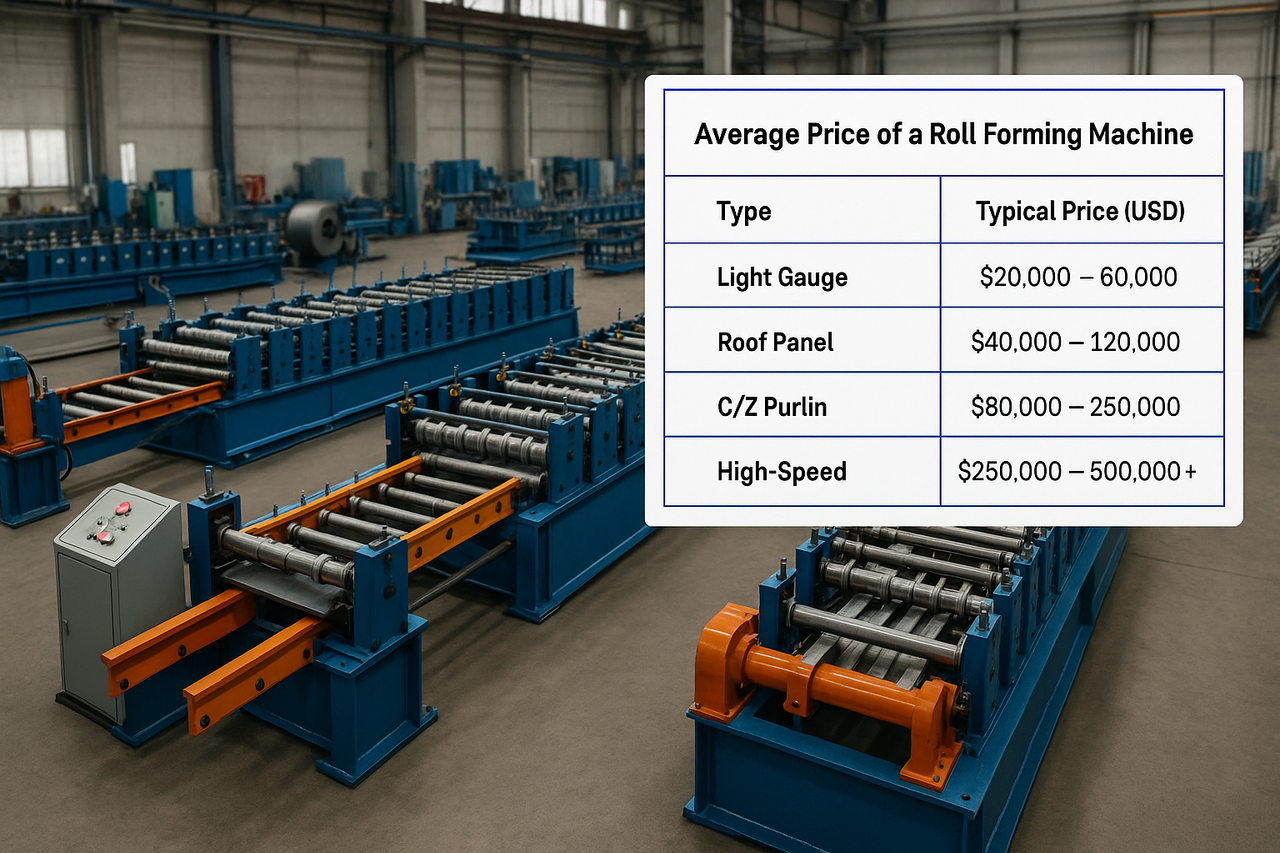

The average price of a roll forming machine can vary widely depending on its type, size, configuration, and degree of automation. Entry-level light-gauge machines may start at around $20,000, while advanced structural or high-speed production lines can exceed $500,000.

At Machine Matcher, all machines are custom-built to your profile and specifications, with prices tailored to your coil width, gauge, material type, and production speed.

| Machine Type | Typical Price Range (USD) | Description |

|---|---|---|

| Light Gauge Stud & Track Roll Former | $20,000 – $60,000 | For drywall and light framing production. Compact and affordable. |

| Roof Panel Roll Forming Machine | $40,000 – $120,000 | Produces corrugated, trapezoidal, or standing seam profiles. |

| C/Z Purlin Roll Forming Machine | $80,000 – $250,000 | For structural steel purlins used in large buildings. |

| Deck Roll Forming Machine | $150,000 – $350,000 | Heavy-duty line for floor decking and composite slabs. |

| High-Speed Metal Roofing Line (with Punching & Flying Shear) | $250,000 – $500,000+ | Advanced automation, PLC controls, and servo cutting. |

| Tube & Pipe Mill | $100,000 – $600,000+ | Designed for round, square, and rectangular tubes. |

| Custom Profile Roll Former | $50,000 – $300,000 | Built for specialized flashings, trims, or channels. |

Profile Complexity – Machines that form multiple shapes, or require interchangeable tooling, cost more.

Material Thickness – Heavier gauges (above 1.5 mm) need stronger frames and higher torque motors.

Automation Level – Servo motors, automatic stackers, and coil cars increase cost but boost efficiency.

Production Speed – A high-speed line (30–60 m/min) requires precision rollers, encoder control, and advanced PLCs.

Punching & Cutting Systems – Hydraulic or servo flying shear systems add to cost but improve output precision.

Country of Manufacture – Machines built in Europe or the USA typically cost more than those from Asia due to labor and component costs.

Shipping, Installation, and Training – Always include logistics, customs clearance, and operator training in your budget.

| Item | Estimated Cost (USD) |

|---|---|

| Roll forming base machine | $80,000 |

| Hydraulic cutting unit | $12,000 |

| PLC control system (Siemens/Delta) | $8,000 |

| Decoiler (5-ton) | $6,000 |

| Hydraulic station | $3,000 |

| Spare roller set | $4,000 |

| Installation & training | $5,000 – $10,000 |

| Total Estimated Price | $118,000 – $125,000 |

💡 Tip: Always request a full quotation including spare parts, training, and warranty terms before placing an order.

Machines in Germany, Italy, and Poland tend to cost 10–25% more due to CE certification and stricter quality standards.

Domestic machines can range from $150,000 to $500,000, but importing from Asia or Eastern Europe may reduce costs by 30–40%.

Most buyers source from China or Turkey, with average prices around $40,000–$150,000 for roofing and purlin machines.

Competitive pricing with strong after-sales support. Machines typically range from $25,000 to $100,000, depending on configuration.

Hydraulic decoilers with coil car tippers

Servo or encoder-controlled flying shear systems

Automatic stackers and conveyors

Remote PLC monitoring systems (for diagnostics and support)

Tooling for multiple profiles

Leveling and feeding systems

Cooling or lubrication systems

These features increase the overall cost but reduce labor, increase safety, and improve production accuracy.

When budgeting, factor in:

Machine base cost

Shipping and insurance

Import duty and taxes

Installation and commissioning

Spare parts and consumables

Operator training and safety equipment

A safe rule of thumb:

Your total project budget should be 20–30% higher than the machine cost alone.

| Category | New Machines | Used Machines |

|---|---|---|

| Price | Higher (custom-built) | Lower initial cost |

| Customization | Fully customizable | Limited to existing profile |

| Warranty | 1–2 years typical | Often sold “as-is” |

| Support | Full technical & remote PLC support | Depends on seller |

| Lifespan | 15–25 years | 5–10 years remaining |

Machine Matcher supplies only new, custom-built machines — ensuring full performance testing, warranty coverage, and compliance with your local power and safety standards.

Machine Type: C Purlin Roll Forming Machine

Material Thickness: 1.5 – 3.0 mm galvanized steel

Profile Width: 100 – 300 mm

Forming Stations: 18

Speed: 25 m/min

Cutting System: Hydraulic flying shear

PLC: Siemens with touchscreen HMI

Estimated Price: $145,000 – $185,000 (FOB)

To receive an exact price, provide:

Profile drawing or sketch

Material type (galvanized, aluminum, etc.)

Coil width and gauge

Required production speed

Power supply details (voltage/frequency)

Destination country and port

Optional extras (stacker, uncoiler, etc.)

Machine Matcher engineers will analyze your data and prepare a custom quotation with delivery, lead time, and warranty details.

Q1: What is the cheapest roll forming machine?

A: Small stud and track roll formers can start at $20,000, ideal for light gauge framing or startup businesses.

Q2: Why do some machines cost over $300,000?

A: These are high-speed or multi-profile production lines equipped with servo drives, punching, flying shear, and automatic stackers.

Q3: How long does a roll forming machine last?

A: With proper maintenance, a well-built machine can last 15 to 25 years or longer.

Q4: Do prices include installation and training?

A: Usually not. Most suppliers quote FOB or CIF prices. Installation, training, and setup are additional and vary by location.

Q5: Can Machine Matcher help find the best price?

A: Yes. Machine Matcher connects you with verified global manufacturers and ensures your quotation meets your technical and financial goals.

The price of a roll forming machine depends on far more than the machine itself — it reflects the level of technology, production efficiency, and reliability you need.

At Machine Matcher, every machine is new, custom-engineered, tested, and supported worldwide. Whether you’re a startup roofing company or a large-scale decking manufacturer, we’ll help you match the right machine to your profile, budget, and market.

Contact Machine Matcher

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.