Posted on Sunday, November 23, 2025

Compressed air is critical for the reliable operation of many roll forming machines — especially those equipped with punching units, pneumatic cutters, flying shears, coil clamps, safety devices, lubricators, and automatic stackers.

A poorly designed air system leads to downtime, weak punching, slow shearing, air leaks, and inconsistent production.

This guide explains why air is needed, how it works, what components you need, and how to size both the piping and the air compressor for your roll forming operation.

Most roll forming machines use pneumatic systems to operate:

Punching cylinders

Notching cylinders

Pre-cut or post-cut shears

Flying shear clamps

Coil clamp systems (on decoilers)

Lubrication or misting systems

Air blow-off nozzles

Safety mechanisms & interlocks

Automatic stacker stops

Material alignment cylinders

Without clean, dry, stable air, these systems will:

Fail to clamp or punch properly

Create weak cuts

Cause misalignment

Slow down cycle speed

Damage tooling

Reduce overall machine output

Air is effectively the muscle that moves many of the machine’s critical components.

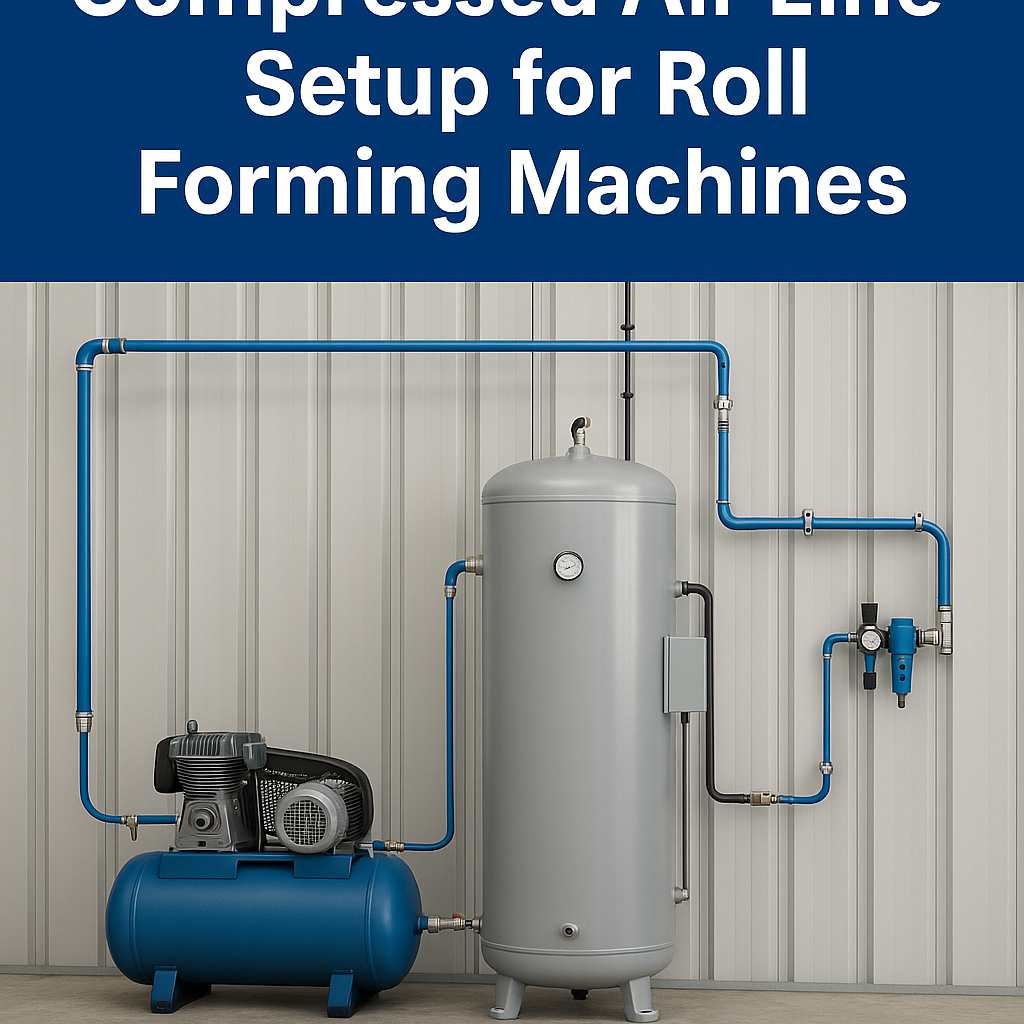

A roll forming machine’s pneumatic system typically includes:

Air compressor – Creates air pressure.

Receiver tank – Stores compressed air to maintain stable supply.

Dryer system – Removes moisture (critical for machine longevity).

Filters & regulators (FRLs) – Clean the air and control pressure.

Piping network – Delivers air to the machine safely.

Pneumatic valves – Direct airflow to cylinders.

Cylinders & actuators – Perform the mechanical action.

The PLC tells the pneumatic valves when to open/close, controlling each motion with precision.

Clean air = consistent punching and cutting.

Dirty/wet air = stuck valves, rusted cylinders, blown seals.

Compressed air powers:

Punch dies (fast, repetitive action)

Notching tooling

Shear clamping

Flying cut-off stabilization

Material hold-down clamps

Coil expansion cylinders

Stacker lifting arms or stops

Air guns for clearing scrap

Lubrication misting

Guard safety activation (in some cases)

Roll forming machines DO NOT use air for the roll forming process itself — only for the automation around the forming line.

You can use:

or

or

They must understand:

Airflow

Pressure drop

Moisture control

Sizing rules

Compressor duty cycles

Pneumatic safety locks

Most factories make the mistake of using a general plumber — this usually results in improper sizing and long-term issues.

For best results:

Machine Matcher can recommend certified compressed-air installers in your region.

Aluminum air pipe (best option)

Stainless steel

Copper

High-pressure rated plastic (PEX-AL-PEX)

❌ PVC — it can explode under pressure

❌ Low-grade rubber hoses — they degrade

❌ Welding air line (dirty inside)

Drop lines with water traps

Slight pipe incline for drainage

Isolation valves for maintenance

Color-coded air lines (optional but recommended)

Shock-proof mounting

Flexible final connection to machine

0.01–0.1 microns filtered

Less than 10% moisture content

Minimal oil contamination

Install the compressor in a ventilated area.

Connect to a receiver tank sized correctly.

Run main piping along the wall or ceiling.

Use drops with drain legs and valves.

Install FRL (Filter–Regulator–Lubricator) unit near machine.

Connect flexible hose from FRL to machine air inlet.

Set correct machine pressure (typically 0.5–0.7 MPa / 70–100 PSI).

Test every cylinder for leaks.

Punching machines MUST have clean, dry air to prevent cylinder seal damage.

Typical airflow consumption:

| Machine Type | Recommended Air Flow |

|---|---|

| Roofing panel roll former | 60–120 L/min (2–4 CFM) |

| Purlin line with punching | 250–700 L/min (9–25 CFM) |

| Decking line with punching | 500–1100 L/min (18–40 CFM) |

| Heavy punching + notching line | 1000–2000 L/min (40–70 CFM) |

Pressure requirement:

0.5–0.7 MPa (70–100 PSI) for most machines.

High punching force = more air usage.

Take the machine’s estimated CFM usage and multiply by 1.5 for reserve capacity.

Small roofing line: 3–5 HP, 10–15 CFM

Standard punching/notching line: 7.5–10 HP, 20–30 CFM

Decking/purlin heavy punching: 15 HP, 40–60 CFM

Large line with many pneumatic stations: 20–30 HP, 70–100+ CFM

Screw compressors (BEST — continuous duty)

Piston compressors (OK for small lines)

An air dryer

A cooling system

Automatic drains

Over-pressure protection

A properly sized receiver tank (at least 250–500L / 60–120 gal)

✔ Level mounting surface

✔ Steel braided hose to reduce vibration

✔ Air dryer installed

✔ Receiver tank drained

✔ Pressure regulator installed

✔ Air leak test performed

✔ FRL tuned to machine’s needs

✔ Moisture traps installed

| Interval | Action |

|---|---|

| Daily | Drain tank, check pressure |

| Weekly | Inspect hoses, check for leaks |

| Monthly | Replace filters, test dryer |

| Quarterly | Check compressor oil, clean intake |

| Annually | Full service / rebuild depending on model |

Skipping air maintenance = blown seals, stuck valves, bad punches, and machine downtime.

Machine Matcher provides:

Air system design & sizing

Compressor recommendations

Full air line installation

Pneumatic troubleshooting

Leak detection

Cylinder repair

FRL system installation

Air dryer setup

Annual maintenance plans

Get your roll forming air system installed properly — avoid downtime, increase punching accuracy, and protect your machine investment.

Machine Matcher now offers full electrical technician services for roll forming machines — including diagnostics, rewiring, testing, encoder calibration, PLC programming, electrical audits, and preventive maintenance.

We support all machine types and all global regions.

Contact us today for immediate technical assistance or to schedule a full electrical inspection at your factory.

Looking for the right roll forming machine or expert guidance on your next project? Machine Matcher is here to help. Our global team provides 24/7 technical support, expert advice, and guidance on machine selection, setup, and maintenance—ensuring your operations run smoothly from day one.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist buyers across the globe. Whether you’re sourcing a single machine or upgrading an entire production line, our experts are ready to provide tailored solutions and support every step of the way.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.