Posted on Monday, November 17, 2025

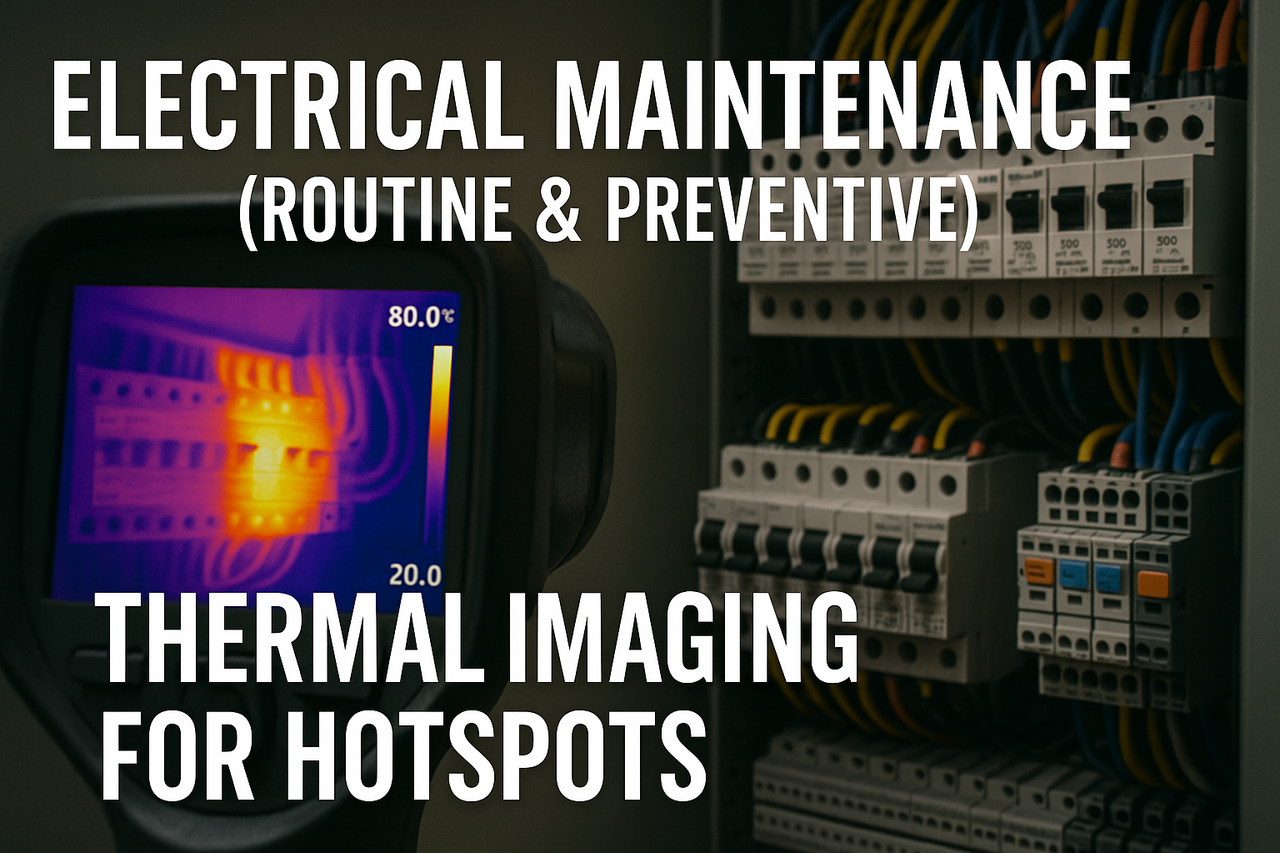

Thermal imaging is one of the most powerful diagnostic tools in modern electrical maintenance. On a roll forming machine, electrical hotspots often develop long before a failure occurs — sometimes weeks or even months ahead of the first noticeable problem.

Using infrared thermal cameras, technicians can detect rising temperatures in:

Electrical terminals

Breakers

Contactors

Overload relays

VFDs and servo drives

Power supplies

Transformers

Motors

Busbars

Encoder power circuits

Safety relays

Cable connections

A hotspot is usually the first sign of a hidden electrical issue such as loose terminals, high resistance, overloaded circuits, harmonics, or failing components. Without thermal imaging, these problems are invisible — until the machine suddenly stops, a breaker trips, or a component burns out.

This guide explains why thermal imaging is essential for roll forming machines, how hotspots develop, and how Machine Matcher technicians use professional infrared inspections to prevent major electrical failures.

Roll forming machines operate in high-load, high-vibration, high-duty environments, making them especially vulnerable to electrical heating problems.

Loose or under-torqued terminals

Breakers and contactors degrading over time

Overloaded motors

VFD and servo drive overheating

Poor grounding or phase imbalance

Harmonics generated by multiple drives

Dust buildup restricting airflow

Undersized cables

Oxidized or corroded connections

Because heat rises gradually before failure, thermal imaging provides early detection and helps prevent:

Motor burnout

Component fires

VFD failure

PLC shutdowns

Random machine stoppages

Costly production downtime

Machine Matcher uses infrared inspections to monitor every heat-critical component.

PLC modules

VFDs

Servo drives

Power supplies

Relays

Breakers

Contactors

Overloads

Terminal blocks

DC power rails

Grounding busbars

Loose terminals

Internal contact welding

DC supply overload

Overheated drive IGBTs

Ventilation failure

Windings

Bearings

Junction boxes

Cable terminations

Overloading

Misalignment

Bearing failure

Weak insulation

Phase imbalance

Harmonics

Overcurrent

Incorrect parameters

Cooling fan failure

Internal board overheating

Bad heat sinks

Hot drives are a major cause of unexpected shutdowns.

Pump motors

Solenoid valves

Coil windings

HPU motor contactors

Overheating here causes pressure loss and hydraulic timing problems.

Although low voltage, these components can still heat due to:

High resistance

Poor shielding

Power supply noise

Loose wiring

This leads to cut-length errors and inconsistent feedback.

Thermal thresholds vary, but general guidelines include:

Normal operating range (depending on component).

Warning zone — rising temperature indicates resistance or load.

Critical zone — failure imminent.

Danger — immediate shutdown or component replacement required.

Machine Matcher uses calibrated infrared tools to measure exact temperatures and compare them to component ratings.

Below are the most common reasons for electrical heating in roll forming machines.

High resistance

Heat buildup

Arcing

Erratic signals

VFD undervoltage

Motor overheating

This is the #1 cause of electrical hotspots.

Undersized motors

Wrong breaker or overload setting

Excessive coil load

Running heavy panels or thick material

Overloaded components run hot before failing.

High harmonic distortion heats:

Transformers

VFDs

Power supplies

Motor cables

Neutral conductors

Common in factories with multiple drives and welders.

Dust and metal debris restrict airflow, causing:

VFD temperature faults

Servo drive derating

Breakers running hot

Old components increase resistance and heat:

Breakers

Contactors

Relays

Overloads

Power supplies

Aging components often show heat months before they fail.

Machine Matcher technicians follow a structured infrared inspection procedure:

Check previous fault logs:

VFD trips

Motor overload history

PLC resets

Sensor instability

Capture thermal images of:

Drives

Contactors

Breakers

Power rails

Modules

Wiring ducts

Load conditions reveal real heating patterns.

Identifies imbalance or overload.

Any component >10–15°C above similar components indicates a fault.

Examples:

Loose terminal

Failing contactor

Blocked ventilation

Undersized cable

VFD with internal damage

Includes:

Infrared images

Temperature readings

Fault description

Risk level

Corrective actions

Replacement recommendations

Thermal imaging is one of the highest ROI maintenance tools available.

We provide:

Full infrared electrical inspections

Load-based temperature analysis

VFD & servo thermal testing

Motor thermal analysis

Breaker/contactors temperature evaluation

Harmonic & grounding diagnostics

Full preventive maintenance packages

Panel cleaning & cooling upgrades

24/7 remote support

Each service includes:

Thermal photos

Temperature reports

Risk scoring

List of improvements

Technician recommendations

Thermal imaging is a critical tool for maintaining healthy electrical systems in roll forming machines. By identifying hotspots before they turn into failures, Machine Matcher helps factories reduce downtime, improve safety, and protect valuable equipment.

Machine Matcher now offers full electrical technician services for roll forming machines — including diagnostics, rewiring, testing, encoder calibration, PLC programming, electrical audits, and preventive maintenance.

We support all machine types and all global regions.

Contact us today for immediate technical assistance or to schedule a full electrical inspection at your factory.

Looking for the right roll forming machine or expert guidance on your next project? Machine Matcher is here to help. Our global team provides 24/7 technical support, expert advice, and guidance on machine selection, setup, and maintenance—ensuring your operations run smoothly from day one.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist buyers across the globe. Whether you’re sourcing a single machine or upgrading an entire production line, our experts are ready to provide tailored solutions and support every step of the way.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.